C6.3.1/0116-0716/E

5

2.5.2 Application limits

For application envelopes please refer to Copeland brand products Select software at

2.6 Design features

2.6.1 Compressor construction

All compressors are fitted with Stream valve plates which cannot be dismantled. To maintain the

high capacity of these compressors in case of exchange, the correct valve-plate-to-body gasket

must always be selected.

Each cylinder head has 2 plugged 1/8" - 27

NPTF tapped holes for connecting high-

pressure switches.

These high-pressure switches must be

calibrated and tested before putting the

compressor into service. They must stop the

compressor if the allowable pressure is

exceeded.

The complete cylinder head is under

discharge pressure.

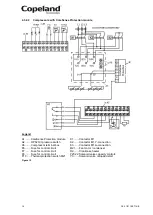

Figure 2

2.6.2 Compressor cooling

Compressor motors must always be cooled, and cylinder head cooling may also be needed at

certain operating conditions.

All Stream compressors are suction gas-cooled. With suction gas-cooled compressors, the

motor is cooled by refrigerant gas that is led over the motor. An additional fan may be required

depending upon the operating conditions (see Copeland brand products Select software at

2.6.3 Demand cooling

"Demand Cooling" as the term implies means liquid refrigerant injection on demand.

For low temperature applications with R407F, R407A, R448A, R449A and R22, Demand Cooling

can be required on the following compressors:

4MF-13X

4ML-15X

4MM-20X

4MT-22X

4MU-25X

6MM-30X

6MT-35X

6MU-40X

NOTE:

R22 is no longer allowed for new refrigeration systems in Europe.

2.6.4 Unloaded start

With direct starting the motor of a compressor is switched directly into the mains by means of a

switch. The resulting breakaway starting current amounts to multiple times the rated motor

current operating maximum, without consideration being given to transient phenomena.

In the case of high-powered motors the breakaway starting currents become so large that they

lead to disruptive voltage dips in the mains. The compressors that are subject to current

limitation must therefore by all means be equipped with starting load reduction to guarantee

perfect starting even when the voltages amount to less than approximately 85% of the voltage

on the nameplate.

2.6.5 Capacity control

For 4M* and 6M* compressors a mechanical capacity control is available. The system used is

blocked suction. Be aware that unloaded operation changes the application range of the

compressor.

NOTE: For the application range of the compressors with capacity control, refer to

Technical Information D7.21.2 "Stream semi-hermetic compressor capacity control".

S

afet

y

in

struct

ion

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Dismant

ling

&

d

ispo

sa

l