16

C6.3.1/0116-0716/E

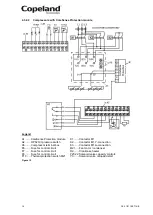

For the electrical connection of the CoreSense Diagnostics module, refer to the wiring diagram

below:

Figure 14: CoreSense module wiring diagram

NOTE: For more information please refer to Technical Information D7.8.4 "CoreSense

™

Diagnostics for Stream refrigeration compressors".

4.6 CoreSense

™ Protection

4.6.1 Motor protection

Stream compressors with "-P" at the end of the description are equipped with a CoreSense

Protection device. The temperature-dependent resistance of the thermistor (also PTC-

resistance) is used to sense the winding temperature. Two chains of three thermistors each

connected in series are embedded in the motor windings in such a manner that the temperature

of the thermistors can follow with little inertia.

The CoreSense Protection module switches a control relay depending on the thermistor

resistance. It is installed in the terminal box to which the thermistors are connected.

Caution: The maximum test voltage for thermistors is 3V.

The total resistance of the thermistor chains on a cold compressor should be ≤ 1800Ω.

Protection class of the module: IP20.

IMPORTANT

Different sources for power supply and contact 11-14! Module

malfunction!

Use the same potential for the power supply (L) and the switch

contact of the control loop (11-14).

Control circuit wiring:

Figure 15: Control circuit wiring diagram