C6.3.1/0116-0716/E

17

4.6.2 Oil pressure control

The oil pressure switch breaks the control circuit when the pressure difference between the oil

pump outlet and the crankcase is too low. The switch must be properly adjusted and tamper-

proof. If the oil differential pressure drops below the minimum acceptable value the compressor

will be stopped after a 120-second delay. After having solved the problem the control has to be

reset manually.

NOTE: Proper oil pressure safety control with an approved switch is a condition of

warranty!

The following oil pressure switches can be delivered as accessories:

Electronic oil pressure switch OPS2

Mechanical oil pressure switch ALCO FD-113ZU

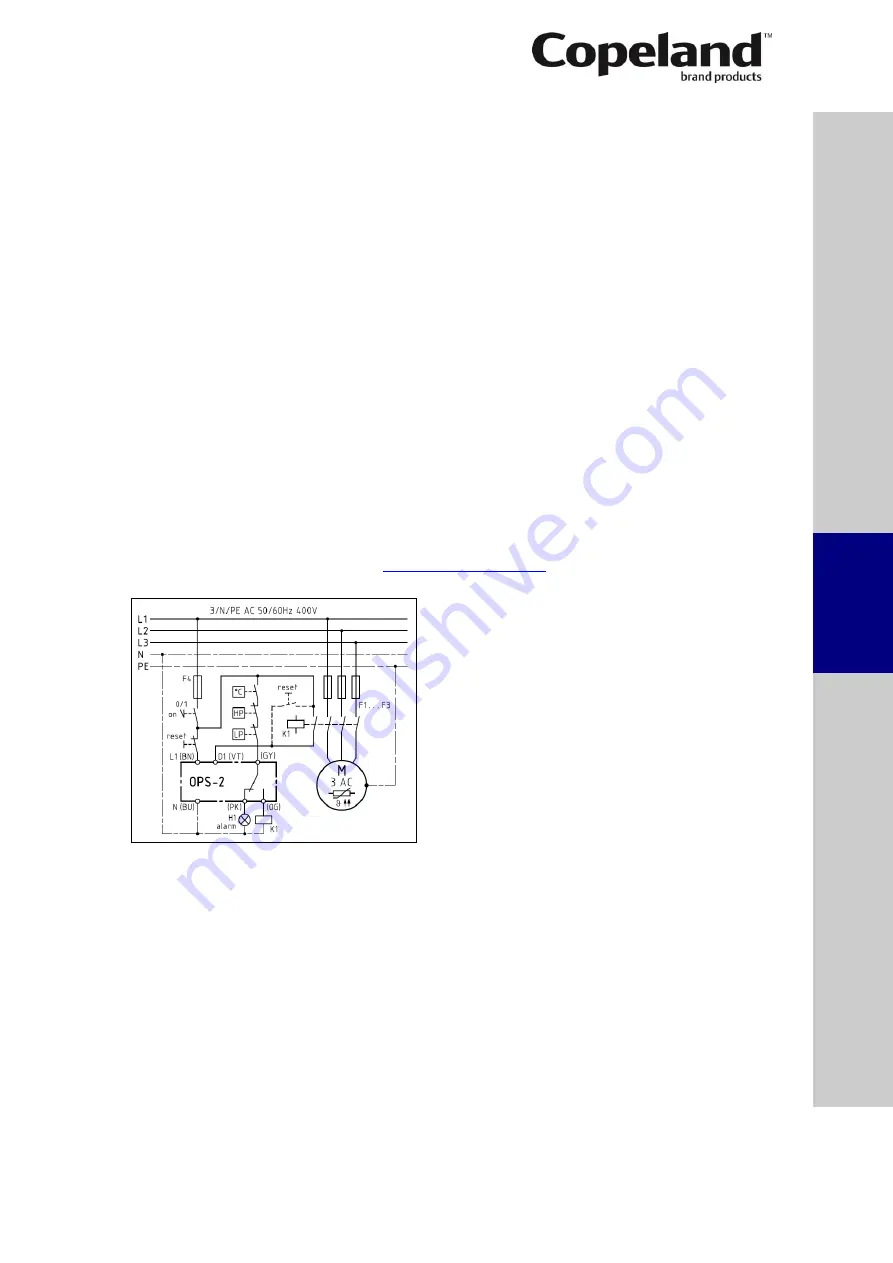

4.6.2.1

Electronic oil pressure switch

– OPS2

The specifications for the OPS2 oil pressure switch are as follows:

Differential pressure:

0.95 ± 0.15 bar

Time delay:

120 ± 15 sec.

Where there is a 5-wire cable connection between the electrical control panel and the

compressor terminal box to the OPS module, the same wires can be applied to the OPS2 which

will give the functions of an OPS1 module.

To obtain use of all of the features of the OPS2 a 7-wire cable between the electrical control

cabinet and the compressor terminal box should be used. Wiring diagrams for OPS2 are shown

in Technical Information D7.8.3 "DWM Copeland

™ Semi-hermetic Compressor Oil Pressure

Differential Switch OPS2" available at

. The wiring diagram relates to an

option using a 7-wire cable.

Wiring:

Brown (BN) = Power supply input

Violet (VIO) = Running signal from the compressor

Grey (GR) = Input changeover contact from the

daisy chain

Orange (OG) = Output changeover contact linked to

the compressor contactor

Pink (PK) = Output changeover contact linked to the

alarm

Blue (BU) = Power supply output

Figure 16

NOTE: Where a 5- or 7-wire cable is stated a 4- or 6-wire cable is required. In some

countries only a 5- or 7-wire cable is available. See more information about OPS2 in

Technical Information D7.8.3 "DWM Copeland

™ Semi-hermetic Compressor Oil Pressure

Differential Switch OPS2".

S

afet

y

in

struct

ion

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Dismant

ling

&

d

ispo

sa

l