C6.3.2/0416-0716/E

7

2.6.3 Digital control

Capacity modulation is achieved by energizing and de-energizing the solenoid valve. When the

solenoid valve is de-energized, the Digital bank capacity is 100%. When the solenoid valve is

energized, the Digital bank capacity is zero. Therefore, the capacity achieved is the time average

capacity.

Example: In a 20-second cycle, if the solenoid is de-energized for 16 seconds, and then

energized for 4 seconds, the resulting capacity will be approximately 80%.

For 4M*D Stream compressors, one bank of the compressor remains loaded 100% while the

Digital bank will modulate 0 to 100% to provide the additional capacity. The capacity is 50 to

100% as one bank is modulating.

On a 6M*D Stream compressor with blocked suction, the blocked suction bank will unload when

demand capacity is less than 67% and load when the demand capacity is higher than 67%. The

Digital bank will continue to load and unload providing continuous capacity across the 33 to

100% range.

2.6.4 Recommended application settings for modulation on Stream Digital compressors

The Digital modulation recommended cycle time is 20 seconds. For other values, check with

Application Engineering.

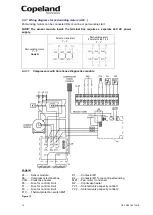

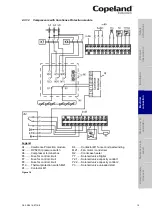

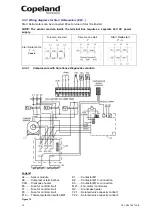

Figure 6: The digital signal from the controller activates the unloading

The load and unload times will give the compressor an operating range during a 20-second

cycle. Minimum percent capacity would be 50% for 4M*D and 33% or 67% for 6M*D, depending

on compressor configuration. The compressor can also operate at a 100% load for the full

modulation sequence.

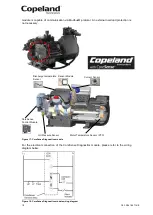

2.6.5 Digital solenoid valve / Gaskets

Due to the high life cycle requirements in a hot gas environment, a special valve has been

developed. Due to reliability requirements, only Emerson solenoid valves may be used. All

compressor warranties are null and void if the Emerson valve is not used. Solenoid coils will be

sold separately for all Stream Digital compressors.

The solenoid coil is available for several voltages: 24V, 120V and 240V.

Stream Digital compressors use special head and valve plate gaskets which have modifications

to ensure gas flow for proper Digital modulation. Only Emerson gaskets may be used. All

compressor warranties are null and void if the Emerson gaskets are not used.

2.6.6 Compressor cooling

Compressor motors must always be cooled, and cylinder head cooling may also be needed at

certain operating conditions.

All Stream Digital compressors are suction-gas cooled. With suction-gas cooled compressors,

the motor is cooled by refrigerant gas that is led over the motor. An additional fan may be

required

depending

upon

the

operation

conditions

(see

Select

software

at

).

2.6.7 Unloaded start

With direct starting the motor of a compressor is switched directly into the mains by means of a

switch. The resulting breakaway starting current amounts to multiple times the rated motor

current operating maximum without consideration being given to transient phenomena.

S

afet

y

in

stru

ctio

n

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Dismant

ling

&

d

ispo

sa

l