4

C6.3.2/0416-0716/E

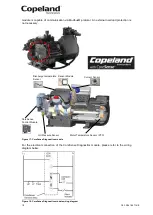

2.4 Nameplate information

All important information for identification of the compressor is printed on the nameplate located

below the compressor oil pump.

The type of refrigerant used should be stamped on the nameplate by the installer.

The year and month of production are shown as a part of the serial number (Jan. = A, Feb. = B,

… Dec. = L).

Figure 1: Nameplate position

2.5 Application range

2.5.1 Qualified refrigerants and oils

WARNING

Use of R450A and R513A refrigerants! Risk of compressor damage!

Refrigerant migration of R450A or R513A into the compressor crankcase

could cause low oil viscosity, which could lead to compressor damage. When

using R450A or R513A it is critical to meet the following requirements:

maintain adequate superheat settings with a minimum superheat of 8-10K;

no liquid refrigerant migration into the compressor at any time, especially

during standstill, during or after defrost, or after reverse mode for example

in heat pumps;

pumpdown is recommended;

the use of a crankcase heater is mandatory;

retrofit to R450A and R513A is only allowed for compressors which are

approved for these refrigerants.

Contact Application Engineering for any further information.

IMPORTANT

It is essential that the glide of refrigerant blends (primarily R407C) is carefully

considered when adjusting pressure and superheat controls.

Oil recharge values can be taken from Copeland

™ brand products Select software available at

Qualified refrigerants

R134a, R404A,

R407A, R407C, R407F,

R448A, R449A, R450A,

R507, R513A

R22

Copeland brand products

standard oils

Emkarate RL 32 3MAF

Suniso 3 GS

Servicing oils

Emkarate RL 32 3MAF

Mobil EAL Arctic 22 CC

Suniso 3 GS, Shell 22-12

Fuchs Reniso KM 32, Capella WF 32

Table 2: Qualified refrigerants and oils for recharging and topping up

To recharge:

When the compressor is completely empty of oil, the amount of oil to be "recharged" is

typically 0.12 litre less than the original oil charge (oil will already be present in the system).

To top up:

During commissioning, planned maintenance or servicing, add oil so that the compressor oil

level is correct.