XW60K 110918 V14.7 EMERSON092718 V14.7

XW60K

9/12

15

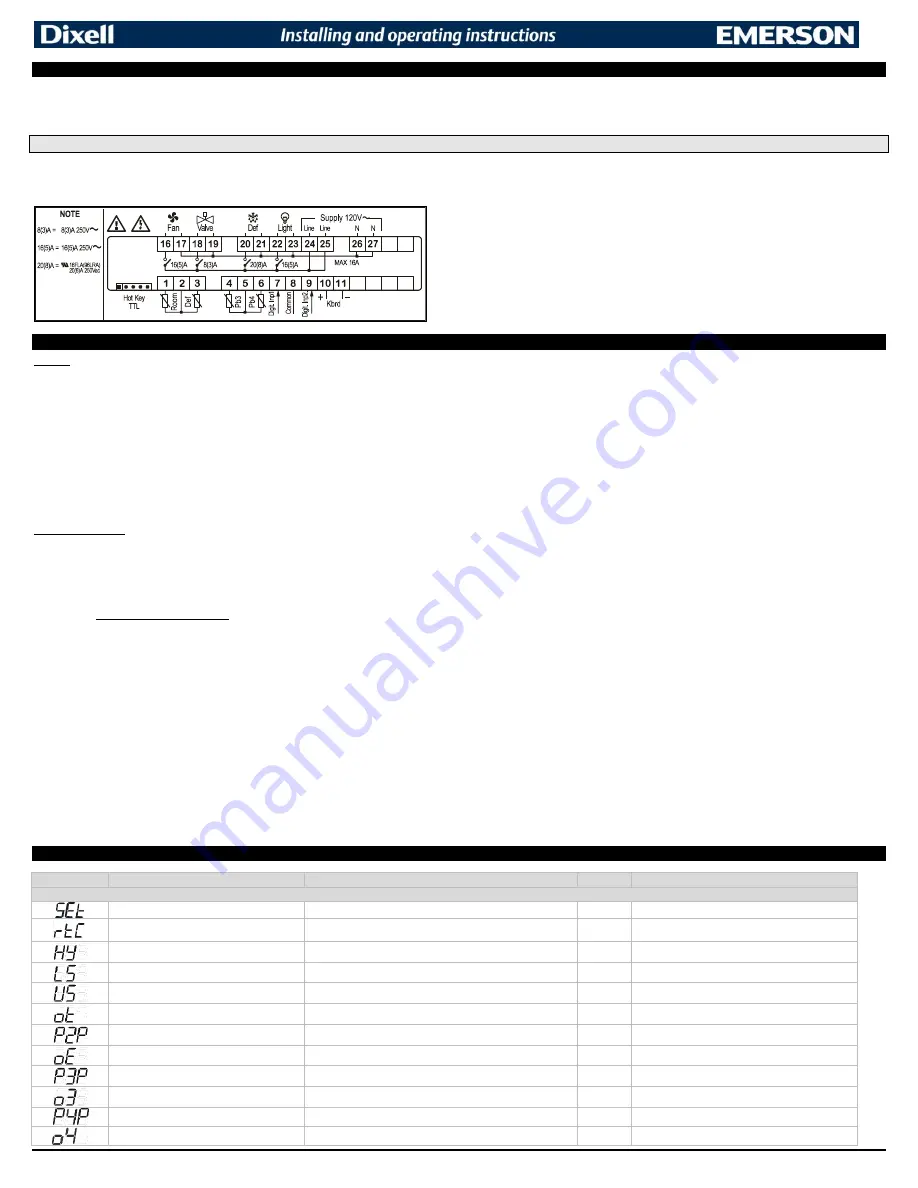

ELECTRICAL CONNECTIONS

XW60K

is provided with screw terminal blocks to connect cables with a cross section up to 2.5 mm

2

for the RS485 (optional) and the keyboard. To connect the other inputs, power supply and relays,

XW60K

is provided with

Faston connections (6.3mm). Heat-resistant cables should

be used. Before connecting cables make sure the power supply complies with the instrument’s requirements. Separate the probe

cables from the power supply

cables, and from the outputs and the power connections. Do not exceed the maximum current allowed on each relay, in case of heavier loads use a suitable external relay.

NOTE:

the maximum current allowed for all the loads is 16A.

15.1

PROBE CONNECTIONS

The probes shall be mounted with the bulb angled upwards to prevent damage due to casual liquid infiltration. It is recommended to place the return air probe to correctly measure the average room temperature. Place the

defrost termination probe among the evaporator fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during defrost, to prevent premature defrost termination. Place the Discharge

Air Probe on the discharge side of the evaporator.

16

Technical data

KeyPads

Housing:

self extinguishing ABS

Case: T620 and T620T:

face 38x185 mm; depth 23mm

VX620:

face 72x56 mm; depth 23mm;

CX620:

face 75x36 mm; depth 23mm

Mounting:

T620T

panel mounting in a 150x31 mm panel cut-out with the 2 metal brackets supplied.

VX620:

panel mounting in a standard J-Box, can be low voltage

CX620:

panel mounting in a 71x29mm panel cut-out

Frontal protection:

IP65 with frontal gasket

Connections:

Screw terminal block

2.5 mm

2

Power supply:

from

XW60K

power module

Display

: 3 digits, red LED, 14.2 mm high

Alarm Output

: buzzer.

Power module XW60K

Case: 8 DN:

140X176X148

Connections:

Screw terminal block

2.5 mm

2

heat-resistant wiring and 6.3mm Faston

Power supply:

230Vac or. 110Vac

10% or 24Vac

Power absorption:

6VA max

Inputs

: 4 NTC or PTC probes

Digital inputs

: 2 free voltage

Relay outputs:

Total current on loads MAX. 16A

Liquid Line Solonoid:

relay SPST 8 A, 250Vac

Fan:

relay SPST 16 A, 250Vac

Defrost:

relay SPST 16A, 250Vac

Light (oA3):

relay SPST 16A, 250Vac

Serial output:

TTL standard

Communication protocol:

Modbus - RTU

Data storing

: on the non-volatile memory (EEPROM)

Kind of action:

1B

Pollution degree:

normal

Software class:

A

Operating temperature:

-10 to 60°C (14 to 140°F)

Storage temperature:

-25 to 60°C (-13 to 140°F)

Relative humidity:

20 to 85% (no condensing)

Measuring and regulation range:

NTC probe:

-40 to 110°C (-58 to 230°F)

PTC probe:

-50 to 150°C (-58 to 302°F)

Resolution:

0.1°C or 1°C or 1°F (selectable)

Accuracy (ambient temp. 25°C):

±0.5°C ±1 digit

17

Default setting values

Label

Name

Range

Default

Level

REGULATION

Set point

LS; US

0

- - -

*

Real time clock menu

(OPTIONAL)

-

-

Pr1

Differential

[0.1 to 25.5°C] [1 to 45°F]

4

Pr1

Minimum set point

[-55.0°C to SET] [-67°F to SET]

-58

Pr2

Maximum set point

[SET to 150°C] [SET to 302°F]

230

Pr2

Thermostat probe calibration

[-12 to 12°C] [-21 to 21°F]

0

Pr1

Evaporator probe presence

n=not present; Y=pres.

yes

Pr1

Evaporator probe calibration

[-12 to 12°C] [-21 to 21°F]

0

Pr2

Discharge Air Probe presence

n=not present; Y=pres.

no

Pr2

Third probe calibration

[-12 to 12°C] [-21 to 21°F]

0

Pr2

Fourth probe presence (opt. cond. probe)

n=not present; Y=pres.

no

Pr2

Fourth probe calibration

[-12 to 12°C] [-21 to 21°F]

0

Pr2