EC2-311_65081_EN_R08.doc

Replacement for Rev.:06

1 / 4

PCN: 864 911 20.03.2008

EC2-311 Display Case and Coldroom Controller

Operating Instructions

GB

Note: This document contains short form instructions for experienced users.

Use last column in List of Parameters to document your individual settings.

More detailed information can be found in the User Manual.

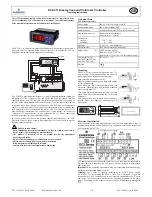

The EC2-311 is a dedicated refrigeration controller with superheat control and a

driver for an Alco Controls Electric Control Valve EX2. In addition the EC2-311

controls air temperature and manages defrost and fan(s).

Network

1

2

3

4

5

6

7

9

8

Two ECN-Pxx pipe temperature sensors (1) and (2) measure saturated suction gas

temperatures at the evaporator inlet and outlet and feed the signals into the

superheat control loop. The superheat controller output modulates the opening of

the EX2 pulse width modulated Electrical Control Valve (6) thus optimising the

refrigerant mass flow through the evaporator. The ECN-Sxx air temperature

sensors (3) and (4) measure air-in and air-out temperature of the evaporator and

feed signals into the air temperature thermostat. The ECN-Fxx fin sensor (5) is

used for defrost termination. The controller has 3 relay outputs to control the

compressor (7), defrost heater (9) and evaporator fan (8). Please consult the

technical data (right) for input and output ratings.

In case of power loss, due to the positive shut-off characteristics of the EX2

Electrical Control Valves, a liquid line solenoid valve is not needed to prevent

flooding of the compressor.

!

Safety instructions:

•

Read installation instructions thoroughly. Failure to comply can result in

device failure, system damage or personal injury.

•

The product is intended for use by persons having the appropriate

knowledge and skills.

•

Ensure electrical ratings per technical data are not exceeded.

•

Disconnect all voltages from system before installation.

•

Keep temperatures within nominal limits.

•

Comply with local electrical regulations when wiring

Technical Data

EC2 Series Controller

Power supply

24VAC ±10%; 50/60 Hz; Class II

Power consumption

20VA max including EX2.

Communication LonWorks®

Interface, FTT10, RJ45 connector

Plug-in connector size

Removable screw terminals

wire size 0.14 … 1.5mm

2

Temperature

storage

operating

-20 … +65°C

0 … +60°C

Humidity

0…80% r.h. non condensing

Protection class

IP65 (front protection with gasket)

Output relays (3)

SPDT contacts, AgCdO

Inductive

(AC15)

250V/2A

Resistive (AC1) 250V/8A; 12A total return current

Triac output for EX2

Electrical Control Valve

Coil (ASC 24V only)

24VAC, 0.1 … 1A

Marking

Mounting

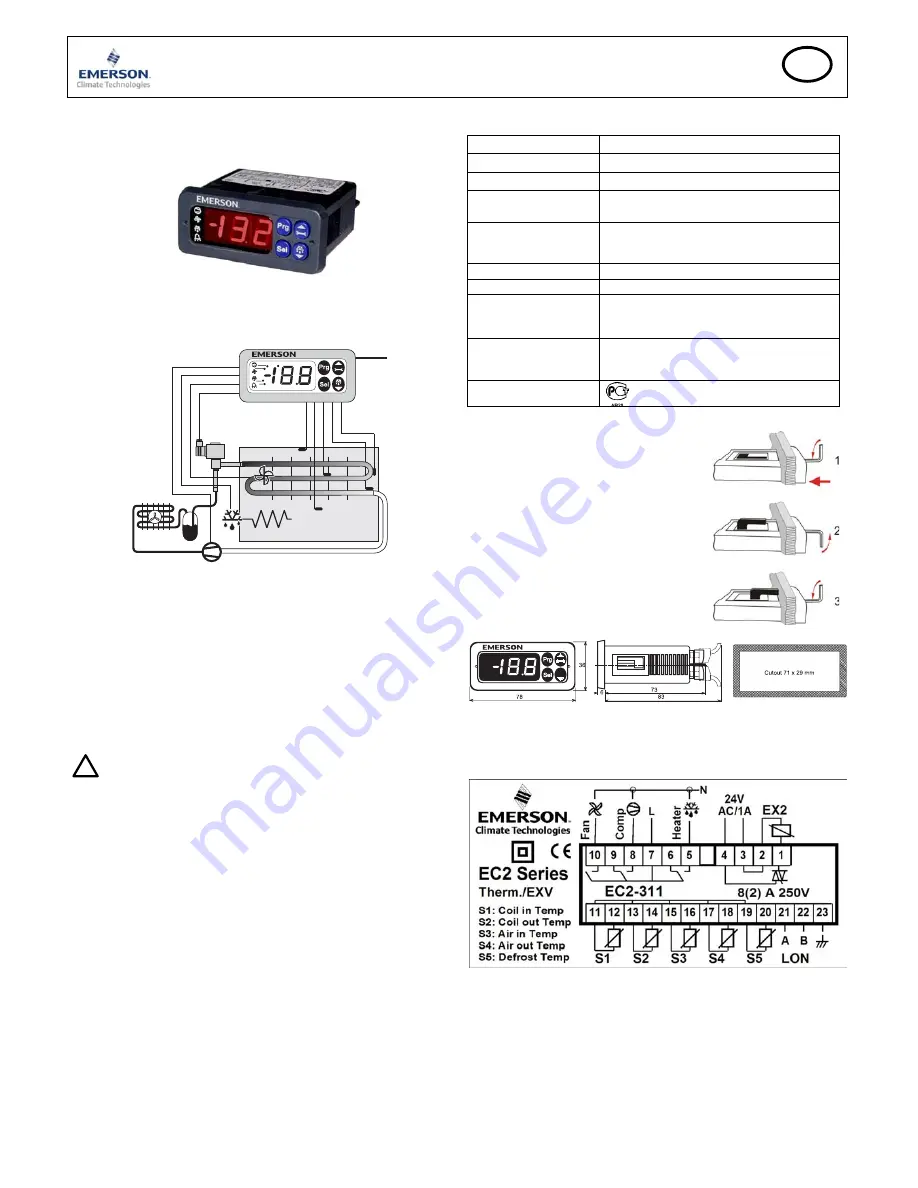

The EC2-311 can be mounted in panels with a 71 x

29 mm cutout. See dimensional drawing below for

space requirements including rear connectors.

Push controller into panel cutout.(1)

Make sure that mounting lugs are flush with outside

of controller housing

Insert allen key into front panel holes and turn

clockwise. Mounting lugs will turn and gradually

move towards panel (2)

Turn allen key until mounting lug barely touches

panel. Then move other mounting lug to the same

position (3)

Tighten both sides very carefully until controller is

secured. Do not over tighten as mounting lugs will

break easily.

Electrical Installation

Refer to the electrical wiring diagram (below) for electrical connections. A copy of

this diagram is labeled on the controller. Use connection wires/cables suitable for

90°C operation (EN 60730-1)

EC2 analog inputs are for dedicated sensors only and should not be connected to

any other devices. Connecting any EC2 inputs to mains voltage will permanently

damage the EC2.

Important:

Keep controller and sensor wiring well separated from mains wiring.

Minimum recommended distance 30mm.

Warning:

Use a class II category transformer for 24VAC power supply

(EN 61558). Do not ground the 24VAC lines. We recommend to use one

transformer per EC2 controller and to use separate transformers for 3

rd

party

controllers, to avoid possible interference or grounding problems in the power

supply. Connecting any EC2 inputs to mains voltage will permanently damage the

EC2.