EC2-311_65081_EN_R08.doc

Replacement for Rev.:06

2 / 4

PCN: 864 911 20.03.2008

EC2-311 Display Case and Coldroom Controller

Operating Instructions

GB

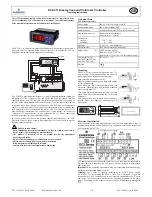

Recommended Sensor Positions in Detail:

(1) ECN-Pxx coil-in temperature sensor: Position on the first return bend of the

evaporator.

(2) ECN-Pxx coil-out temperature sensor: Position directly after the evaporator on

the common suction line.

(3) ECN-Sxx air-in temperature sensor: Position in the middle of the cabinet as

high as possible.

(4) ECN-Sxx air-out temperature sensor: Position asymmetric closer to the

expansion valve as high as possible.

(5) ECN-Fxx fin temperature sensor: Position on the evaporator, asymmetric closer

to the expansion valve.

Recommendations for mounting both pipe sensors: Insure proper thermal contact

by using a metallic pipe clamp or temperature resistant plastic straps. Do not use

standard plastic tie wraps (as used for electrical wiring) as they may become loose

over time, which could result in faulty temperature measurements and poor

superheat control performance. It is recommended to insulate the pipe temperature

sensor with ARMAFLEX™ or equivalent. The recommended position of the pipe

sensors is between 9 and 3 o’clock as shown in the picture.

Both air temperature sensors should be mounted on spacers in the air duct so that

there is airflow around.

Caution: The sensor cables can be extended if necessary. The connection must be

protected against water and dust.

The superheat control is based on the two temperature sensors (1) and (2). The

coil-in simulates the saturated suction temperature. Though the suggested position

is the first return bend, alternative positions may be selected but the measured

temperature should be checked against the pressure measured at the suction header.

The evaporator outlet temperature sensor should be mounted on the common

suction header of the evaporator. The superheat is calculated from the difference

between these two sensors.

A calibration correction can be made using the parameter u1 (see procedure

below).

Setup and Parameter Modification Using the Keypad

For convenience, an infrared receiver for the optional

IR remote control unit

is

build-in, enabling quick and easy modification of the system parameters when a

computer interface is not available.

Alternatively, the parameters can be accessed via the 4-button keypad. The

configuration parameters are protected by a numerical password. The default

password is “12”. To select the parameter configuration:

•

Press the

PRG

button for more than 5 seconds, a flashing “0” is displayed

•

Press or until “12” is displayed (password)

•

Press

SEL

to confirm password

The first modifiable parameter code is displayed (/1).

To modify parameters see Parameters modification below.

Parameter Modification: Procedure

•

Press or to show the code of the parameter that has to be changed;

•

Press

SEL

to display the selected parameter value;

•

Press or to increase or decrease the value;

•

Press

SEL

to temporarily confirm the new value and display its code;

•

Repeat the procedure from the beginning "

press

or

to show...

"

To exit and save the new settings:

•

Press

PRG

to confirm the new values and exit the parameters modification

procedure.

To exit without modifying any parameter:

•

Do not press any button for at least 60 seconds (TIME OUT).

•

Press “

ESC

” on IR remote control.

Defrost Activation:

A defrost cycle can be activated locally from the keypad :

•

Press the button for more than 5 seconds, a flashing “0” is displayed

•

Press or until “12” is displayed (password)

•

Press SEL to confirm password

The defrost cycle is activated

Special Functions:

The Special Functions can be activated by:

•

Press and together for more than 5 seconds, a flashing “0” is displayed.

•

Press or until the password is displayed (default = 12). If password was

changed, select the new password.

•

Press

SEL

to confirm password, a “0” is displayed and the Special Function

mode is activated.

•

Press or to select the function. The number of special functions is dynamic

and controller dependent. See list below.

•

Press

SEL

to activate the function without leaving the special function mode.

•

Press

PRG

to activate the function and leave the special function mode.

Most of the Special Functions work in a toggle mode, the first call activates the

function, and the second call deactivates the function.

The indication of the function can only be displayed after exiting the special

function mode.

•

0: Display test function

•

1: Clear alarm messages

•

2: Cleaning mode. The cleaning mode is effectively a manual defrost with the

option of the fans on/off. The cleaning mode should not be used in order to

isolate the application for maintenance purposes.

•

3: Fans only

•

4: Set the electronic control valve to 100% open

•

5: Resets all parameters to the factory default setting. The controller will

indicate “oF” during the reset and the valve will close.

Display of Data:

The data to be shown on the display can be selected by the user. In case of an

alarm, the alarm code is displayed alternately with the selected data. The user can

inhibit the alarm code. Press the

SEL

button to scroll through all possible

displayable data.

The display will show for one second the numerical identifier of the data and then

the selected data. After two minutes the display will return to the by parameter /1

selected data.

It is possible to temporarily display the values of the different sensors. This is a

useful feature when initially setting-up the system without the aid of the

WebPages. Press the

SEL

sequentially. The value displayed on the screen

corresponds to the number corresponding to the /1 parameter. Action only valid

when parameter H2 = 3

Logical status of compressor relay

LON service LED

Logical status of fan relay

Logical status of defrost heater relay

Alarm condition

IR LED