TM

10

Installation Operation & Maintenance manual ELQ

DOC.55.EDN Rev: E

October 2012

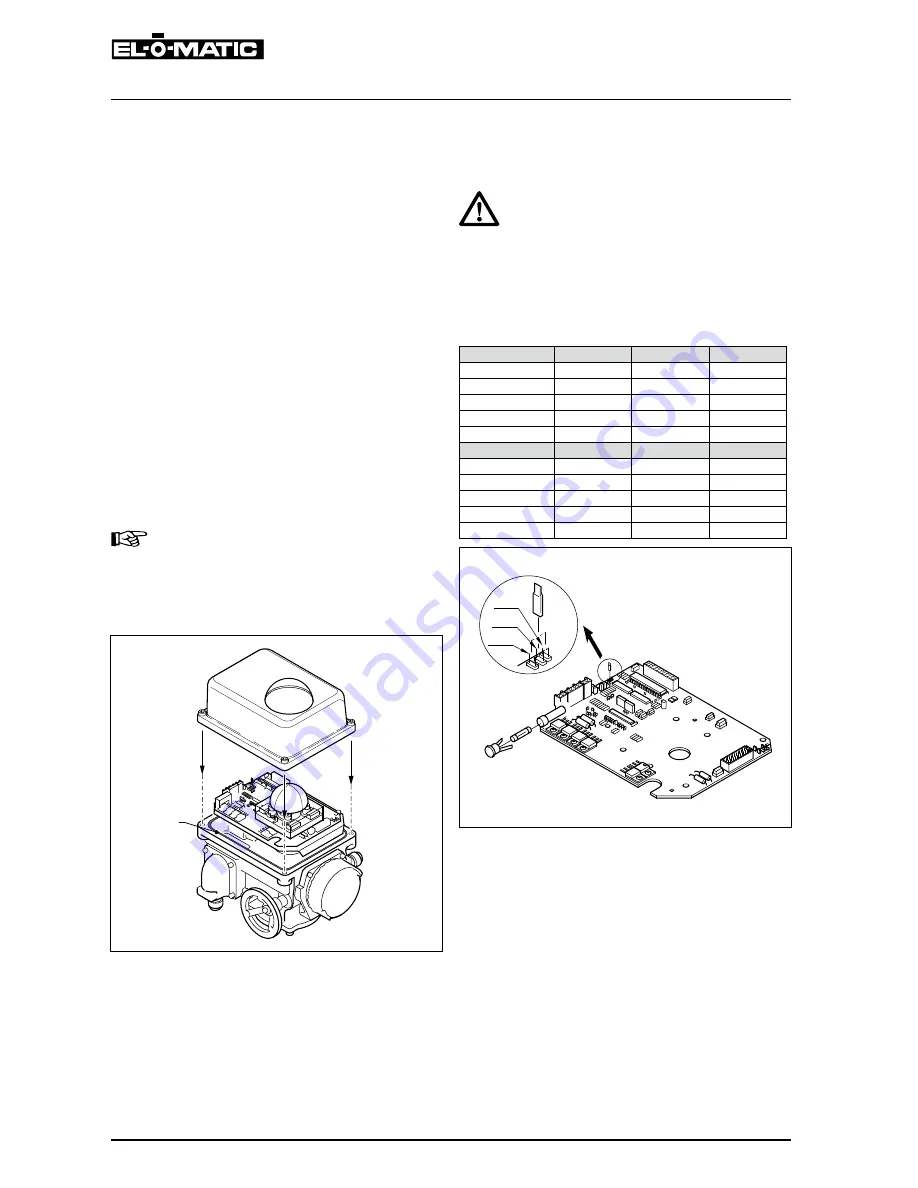

Jp1

Jp2

Jp3

1

"Closed" position:

7. Move the valve to about 15° before the fully

“closed” position with the manual override hand

wheel.

8. Turn the “closed” mechanical stop screw out

(CCW) 4 turns.

9. Move the valve to the fully closed position with

the manual override hand wheel.

10. Turn “Motor switch closed”-cam (CCW) until

switch trips.

For position indication set the limit switches as

follows:

Turn “Motor switch closed”-cam (CCW) until

switch trips.

11. Turn the “Closed” mechanical stop screw in (CW)

until an obstruction is felt (do not force) then

back-off 3 turns and lock the mechanical stop

screw with the locknut.

Important

•

After adjustments always mount the cover to

the housing or continue with chapter 5.

•

Take care that the cover seal is in place to

comply to dust and water tightness according

to IP65, IP67 or NEMA4.

4.2

torque setting

4.2.1 Jumper setting maximum torque

Warning

Be sure that the jumper is placed at one of

the three jumper positions.

The ELQ is factory set at its maximum output torque.

The output torque can be reduced by means of a

jumper (see table 4.2).

table 4.2 jumper setting maximum torque

Metric data

jp1

jp2

jp3

ELQ 100

100 Nm.

80 Nm.

55 Nm.

ELQ 200

200 Nm.

160 Nm.

130 Nm.

ELQ 300

300 Nm.

250 Nm.

210 Nm.

ELQ 500

500 Nm.

430 Nm.

360 Nm.

ELQ 800

800 Nm.

700 Nm.

600 Nm.

Imperial data

ELQ 100

885 In.Ibf

708 In.Ibf

487 In.Ibf

ELQ 200

1770 In.Ibf

1416 In.Ibf

1151 In.Ibf

ELQ 300

2655 In.Ibf

2213 In.Ibf

1859 In.Ibf

ELQ 500

4425 In.Ibf

3806 In.Ibf

3186 In.Ibf

ELQ 800

7081 In.Ibf

6196 In.Ibf

5310 In.Ibf

4.1.1 Mount cover