TM

13

Installation Operation & Maintenance manual ELQ

DOC.55.EDN Rev: E

October 2012

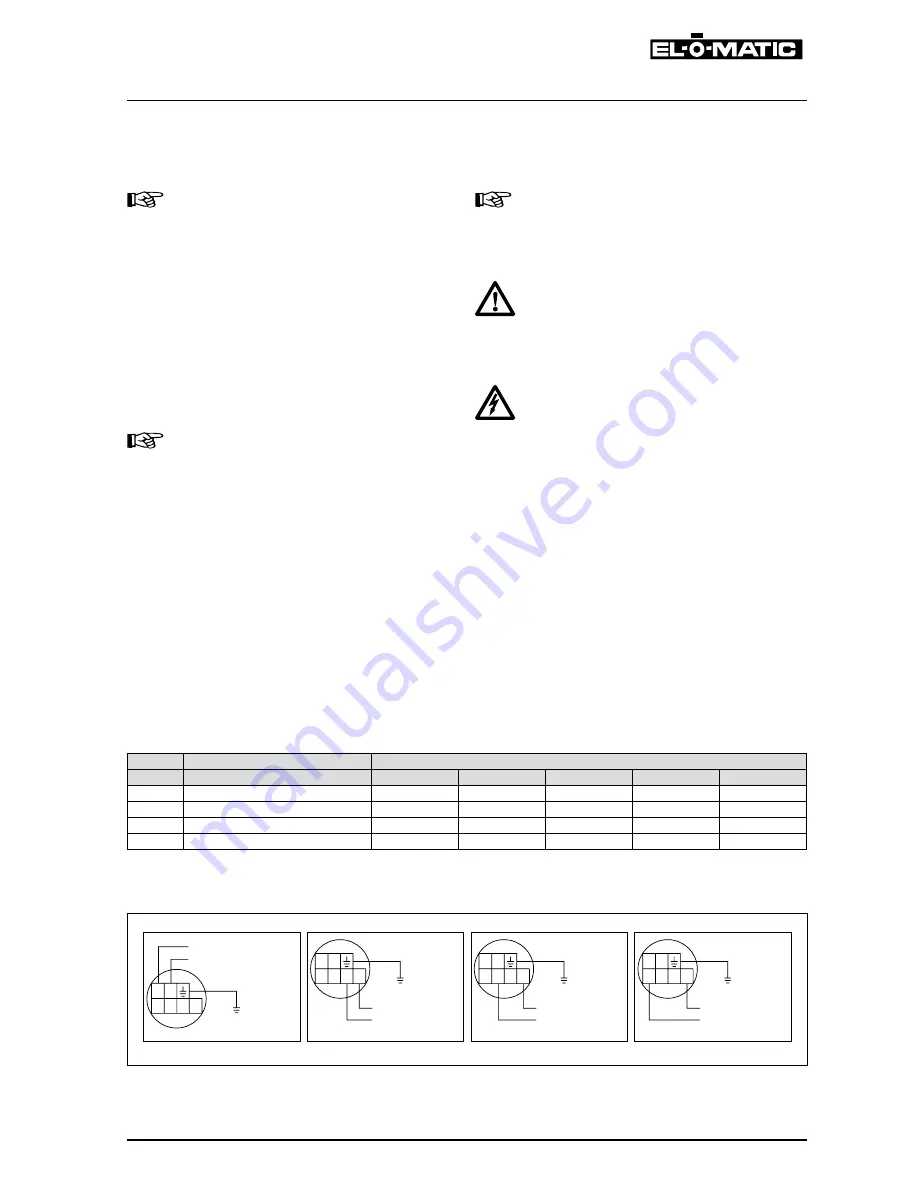

6.1.1 Power supply terminals

5

3 2 1 0

4

5

3 2 1 0

4

5

3 2 1 0

4

N 115 VAC

50/60Hz

(+10% / -6%)

L1

N 230 VAC

50/60Hz

(+10% / -6%)

L1

24 VDC (+10%)

+

-

400 VAC

50/60Hz

(+10% / -6%)

L2

L1

5

3 2 1 0

4

Note

-

Before connecting the power supply connect

all options properly (see option instructions).

-

Ground properly.

-

When supplying three phase current connect

a maximum of three wires, two phases and

earth.

-

Use and mount cable glands or blindplugs as

required by national or local legislation.

-

When IP65, IP67 or NEMA4X ingress protec

-

tion is required, the electrical entries must be

fitted with equivalent or higher rated glands

or blindplugs.

AtEX Installation instructions

-

See chapter 1.2 for use of Flameproof ELQ

actuators in ATEX classified hazardous ar

-

eas.

requirement for Factory Mutual (FM)

The 24 VDC power supply has to be protect

-

ed by a power limited circuit (< 30 VDC and

max. 150 W).

Warning

The actuator should be externally protected

by a fuse.

AC: Fuse min. 2.5 Amp.

DC: Fuse min. 10 Amp.

Warning

When power is supplied on for instance ter

-

minals, 4 and 5 (for 24VDC), then the other

terminals will output their respective (high)

voltage.

6.1

Power supply specification

The power print is designed so that four basic types of power can be supplied to the actuator (see table 6.1

and figure 6.1.1)

Table 6.1 Power supply specification

terminal Voltage range

Maximum current *

ELQ-100

ELQ-200

ELQ-300

ELQ-500

ELQ-800

0 - 1

115 VAC (+10% /-6%) 50/60 Hz

1 A

1 A

1 A

1.7 A

1.7 A

0 - 2

230 VAC (+10% /-6%) 50/60 Hz

0.5 A

0.5 A

0.5 A

0.9 A

0.9 A

0 - 3

400 VAC (+10% /-6%) 50/60 Hz

0.3 A

0.3 A

0.3 A

0.5 A

0.5 A

4 - 5

24 VDC (+10%)

4.1 A

4.3 A

4 A

5.3 A

5.1 A

*

Max. current when all options mounted and under full load.

6

CONNECtING POWEr SUPPLy

Wiring dimensions for power and earth connection: Max. 2.5mm

²

/ 14 AWG. Tightening torque: 0.8Nm / 7 in/lb.