TM

17

Installation Operation & Maintenance manual ELQ

DOC.55.EDN Rev: E

October 2012

9

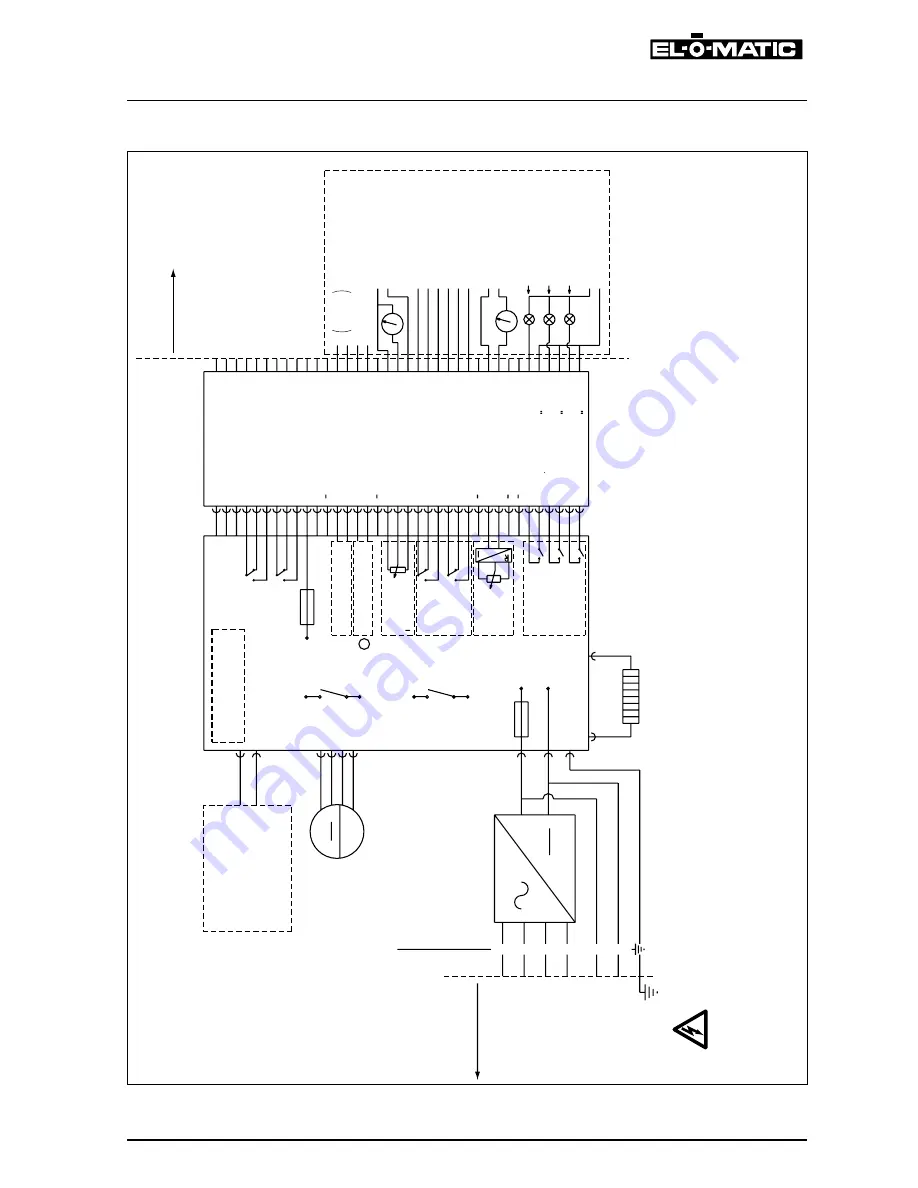

WIrING DIAGrAM

+

-

4-20 mA

0-10

VD

C

RS232

4-20 mA

+

-

-

+

400

V

230

V

115

V

0

V

+24

VDC

GND

3

2

1

0

5

4

MS

1

MS

2

+24

V

+24

V

GND

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

M

Field wir

ing

Po

wer supply

Field wir

ing

Control signals

Connector board

OPTION CONNECTIONS

MS1 = motor

sw

itch

“Open”

MS2 = motor

sw

itch

“Closed”

The motor stops when motor

sw

itch reaches

the opened or closed position.

Electronic Control Unit (ECU)

Optional

: plug in

Speed Control

Connectornr.

Optional

:

Local Control Statio

n

functions:

Po

wer supply

Remot

e

Local open

Local close

Of

f

brak

e

Open - connect 24VD

C

Close - connect 24VD

C

Common

Limit Switch closed COM

Limit Switch closed NC

Limit Switch closed NO

Limit Switch open COM

Limit Switch open NC

Limit Switch open NO

+ 24V Output

GND Output

I in

+

I in

-

Communication lin

e

Communication lin

e

Po

tmeter

+

Po

tmeter

va

r.

Po

tmeter

-

Extra limit Switch 3 COM

Extra limit Switch 3 NC

Extra limit Switch 3 NO

Extra limit Switch 4 COM

Extra limit Switch 4 NC

Extra limit Switch 4 NO

Po

sition

Tr

ansmitter

+

Po

sition

Tr

ansmitter

-

Status input Motor r

unning

Status output

Status input Supply control

Status output

Status output

Status input Local contro

l

Heater 10W

Optional

Status

Module

Optional

Po

sition

Tr

ansmitter

Optional

Extra Limit

Switches

Optional

Po

tentio-

meter

10kOhm

B

Optional

Communication

Optional

Po

sitioner

Fuse

max.

500m

A

CO

M

NC

“Open”

Switc

h

NO

CO

M

NC

“Closed”

Switc

h

NO

Input

24VDC Input

V

max.

30

VDC Input

Motor Running

Po

wer supply connected

ELQ

sw

itched to

Local control station

0-30V DC /

AC

Output

Fuse

max.

10

A

Wa

rnin

g

When po

wer is supplied on

fo

r instance te

rm

inal

s,

4 and 5 (f

or 24VDC), then the other te

rm

inals will

output their respectiv

e (high) v

oltage

.

The ECU contains an electronic torque control

.

Switches are sh

ow

n in the mid position of the stro

ke