Installation

4.3.3

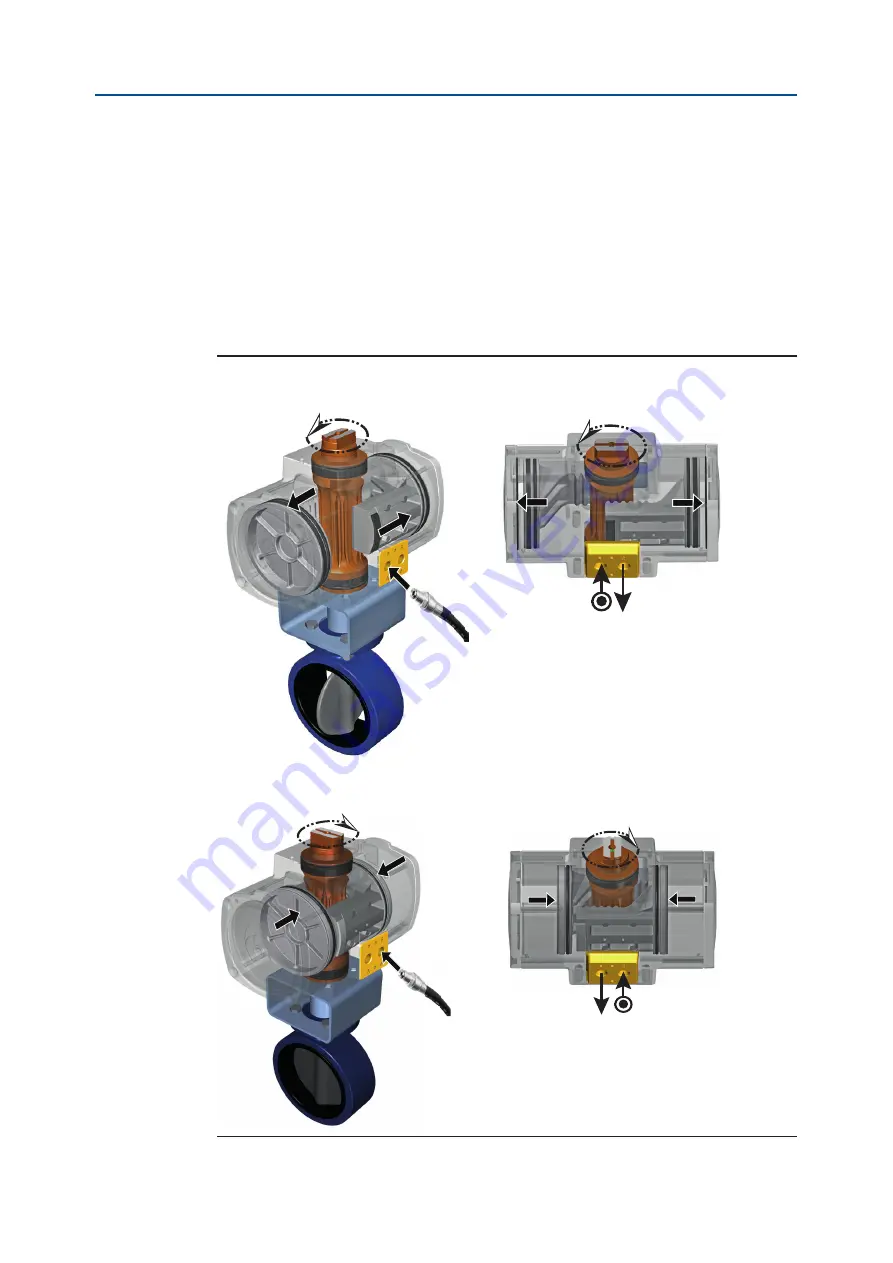

Double-Acting Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

CW (direct acting).

•

Applying supply pressure to port A will move the pistons outward to the "Open"

position of the valve.

•

Applying supply pressure to port B will move the pistons inward to the "Close"

position of the valve.

•

For assembly codes CC, the operating principle is reversed (reverse acting).

Figure 5

Double-Acting Operation

Outward Stroke

A

B

A

Inward Stroke

A B

B

10

September 2015

Installation, Operation and Maintenance Manual

DOC.IOM.EF.EN Rev. 6

Section 4: Installation

Summary of Contents for EL-O-Matic F-Series

Page 2: ......