Disassembly

8.5

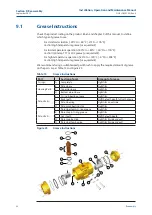

Removing pinion

1.

Remove the circlip (11) and thrust washer (9) on top of the pinion assembly.

Discard if necessary the circlip (11) and thrust washer (9).

2.

Remove the pinion (4) by pushing it downwards.

3.

Remove the pinion o-ring seals (12) and the pinion bearings (8). Discard all of

these parts.

Figure 22

Pinion Removal

12

12

4

8

11

9

8

Table 12.

Recommended circlip pliers according DIN 5254 (or equal)

for shaft circlips.

Actuator size

Pinion top diameter

Pliers according DIN 5254

12

16 mm

0.630"

A1

25 - 100

22 mm

0.866"

A2

150 - 350

36 mm

1.417"

A3

600

55 mm

2.165"

A3

8.6

Cleaning the Body

In case of maintenance, use a clean dry cloth and thoroughly wipe clean and remove old

grease from:

•

The inside and outside of the body including thread holes and crevices/grooves

•

The pinion gears

•

The pistons

28

September 2015

Installation, Operation and Maintenance Manual

DOC.IOM.EF.EN Rev. 6

Section 8: Disassembly

Summary of Contents for EL-O-Matic F-Series

Page 2: ......