Reassembly

9.6

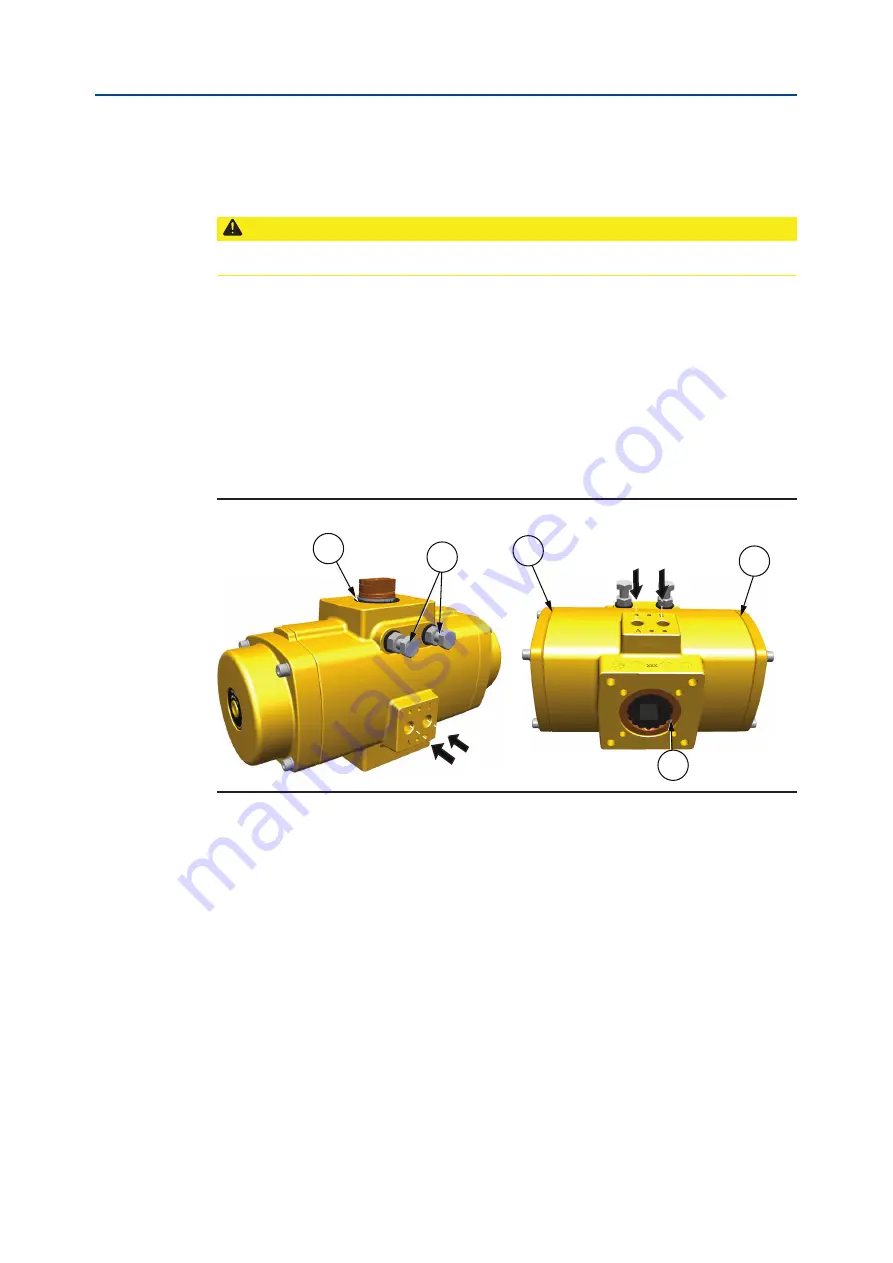

Basic function and Air Leak Test

CAUTION - MOVING PARTS

Applying pressure to the actuator will cause the actuator/valve assembly to operate.

1.

Apply pressure (max. 8 bar/116 psi) to ports A and B. Use some soap suds at the

indicated points: around pinion top (1), pinion bottom (2), the end caps (3) and

limit stops (4).

2.

In case of leakage around:

a.

The limit stop bolts (and/or the spring-package bolt at spring-return

models). Turn the lock nut of the bolts tighter; until the leakage stops.

b.

The end caps: Disassemble the end caps, replace o-rings and reassemble.

c.

The pinion top or bottom and A- or B- port: Disassemble the complete

actuator, replace o-rings and reassemble.

Figure 31

Basic function and air leak test

3

2

A B

3

A

B

1

4

38

September 2015

Installation, Operation and Maintenance Manual

DOC.IOM.EF.EN Rev. 6

Section 9: Reassembly

Summary of Contents for EL-O-Matic F-Series

Page 2: ......