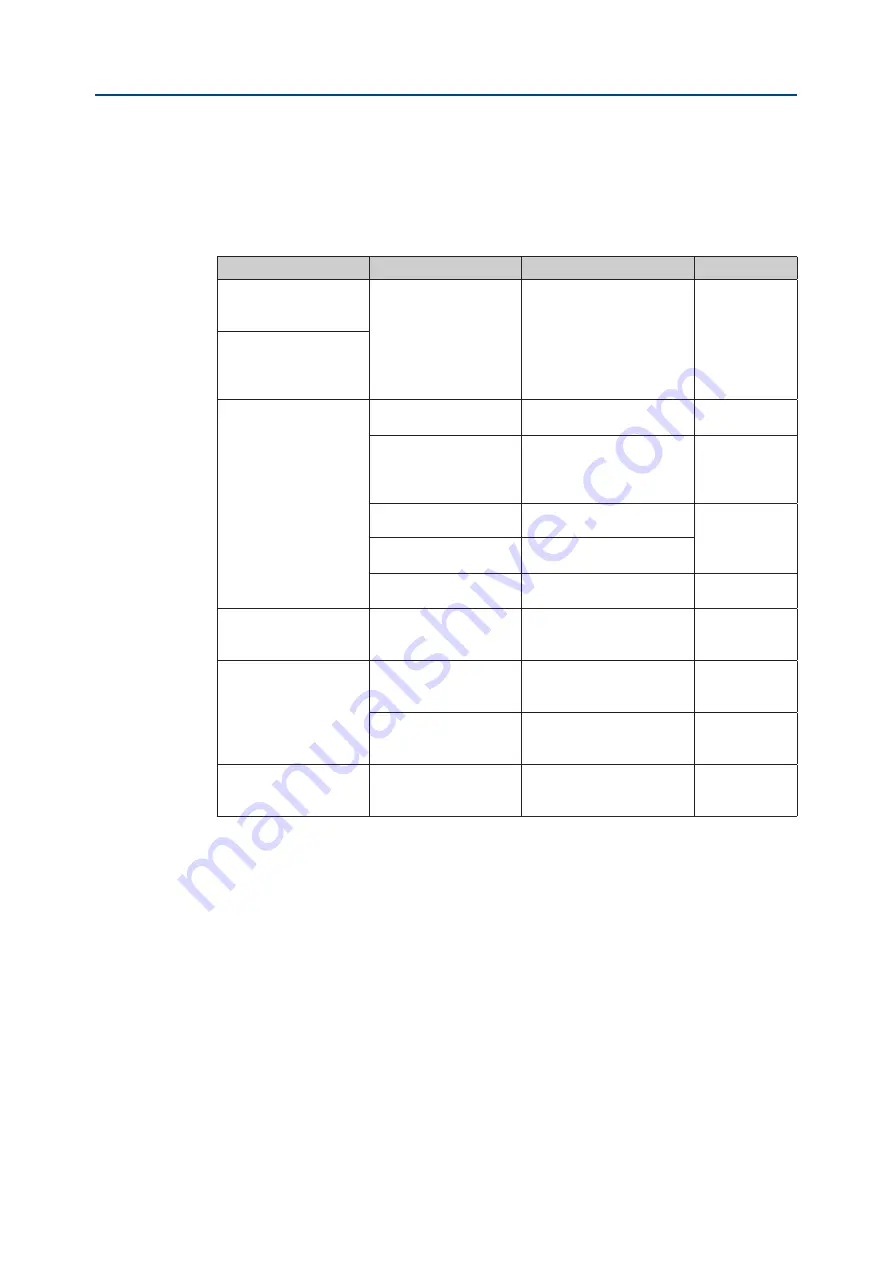

Troubleshooting

Section 10: Troubleshooting

10.1

Mechanical Problems

Problem

Possible error

Solution

Where to find

Feedback position and

actual position are not

the same.

Actuator and valve are

mounted 90° rotated in

relation to each other.

Remove actuator from

valve. Check assembly code

of actuator. Put both valve

and actuator in “Closed”

position. Mount actuator on

valve.

Section 4

Valve is in “Closed”

position, actuator is in

“Open” position and will

not move anymore.

Valve does not reach the

completely “Closed” or

“Open” position.

Limit stop screws are not

set correctly.

Readjust the limit stop

screws.

Section 5

Insert is not mounted

properly.

Mount the insert in the right

position. Remark: Rotate

insert to one cam = 22.5°.

Section 4.5

Pressure to low.

Apply pressure as per sizing.

Sizing is wrong.

Check valve torque data

with actuator torque data.

Pinion is mounted in the

wrong position.

Re assemble actuator.

Section 9

Actuator rotates, valve

does not.

No coupling between

actuator shaft and valve

spindle.

Install a coupling between

actuator shaft and valve

spindle.

Section 4.5

Actuator does not

rotate or does not rotate

smoothly.

Broken gearing on

pistons or pinion.

Contact nearest EL-O-Matic

representative to replace

actuator.

Spring or Spring

cartridge is broken.

Contact nearest EL-O-Matic

representative to replace

actuator.

Appendix A.

Limit stop screws cannot

be turned out anymore.

Limit stop screws is

bend.

Contact nearest EL-O-Matic

representative to replace

actuator.

Installation, Operation and Maintenance Manual

DOC.IOM.EF.EN Rev. 6

September 2015

39

Section 10: Troubleshooting

Summary of Contents for EL-O-Matic F-Series

Page 2: ......