Appendix

Appendix A: Spring load removal

This section explains:

•

How to remove the spring load safely of spring-return actuators in case:

—

The valve gets “stuck” in mid position.

—

One of the spring cartridges is broken.

WARNING - MOVING PARTS

A spring-return actuator mounted on a valve, which is stuck in mid stroke, contains a high

spring load which will cause a sudden rotation of the actuator versus the valve during

disassembly. This can cause serious injury to personnel or damage to material.

On spring-return actuators with a broken spring cartridge, the end cap can be “shot” away

during disassembly of the actuator. This can cause serious injury to personnel or damage to

material.

A.1

Spring load relief

CAUTION - ROTATING ACTUATOR

In case of an actuator/valve assembly “stuck” in mid position, leave the actuator on the

valve and/or mounting bracket during this procedure.

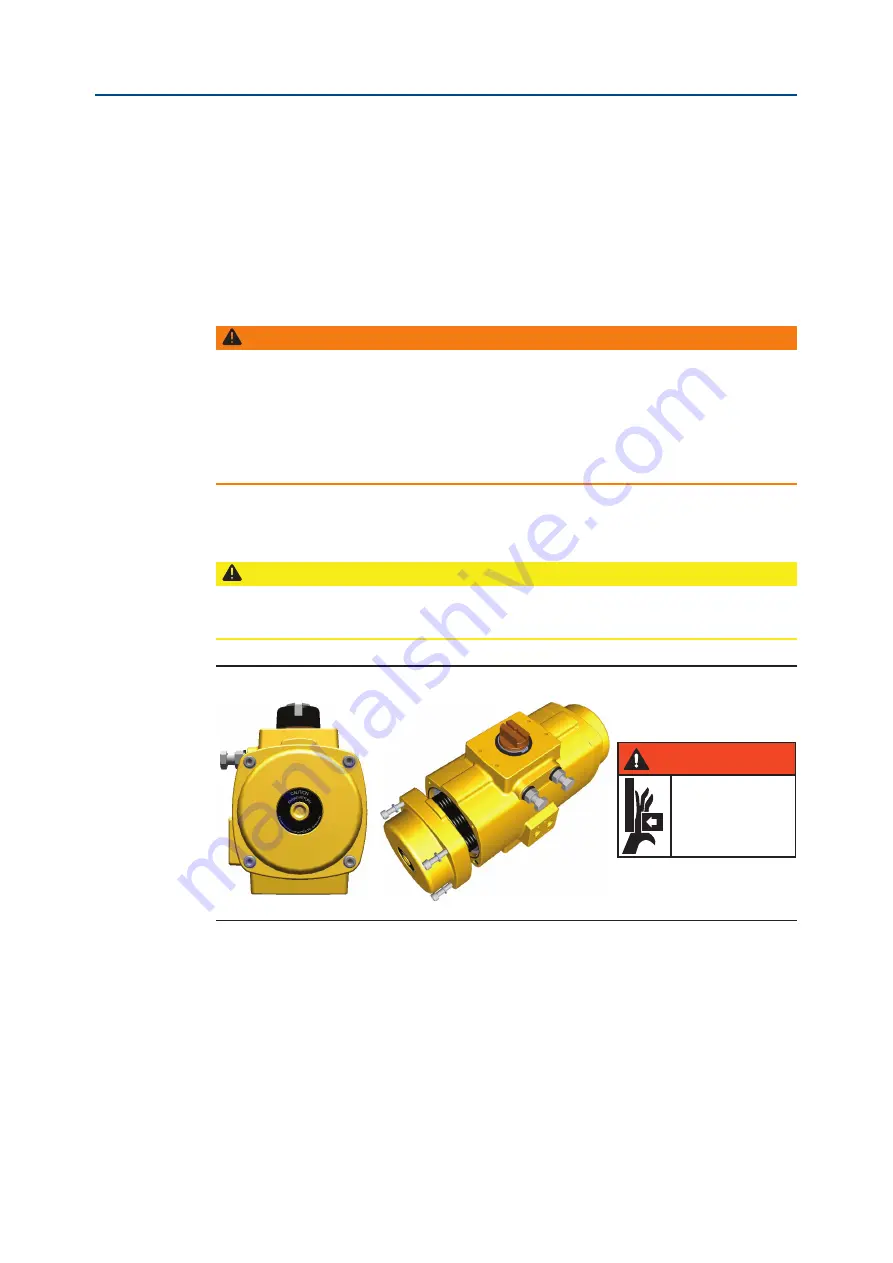

Figure A-1

Spring load removal

Crush / Amputaion Hazard

Failure to follow instructions

for removal of spring loaded

actuator may result in

surious personal injury

WARNING

1.

Depressurize the actuator completely.

2.

Based on the actuator size, choose the correct threaded rod kit from Table A-1.

3.

Replace one by one each end cap screw for the threaded rod kit and turn down the

adjusting nut until it touches the end cap.

4.

Once all for end cap screws have been replaced, gradually turn the adjustment nuts

on threaded rod in CCW direction by turning the nuts half turn at a time. Make sure

the rod itself does not turn. Continue this until the load of springs are relieved.

5.

Repeat the same procedure for the end cap screws on the other size of the

actuator as shown in figure A-1.

6.

In case of an actuator/valve assembly “stuck” in mid position: The actuator now

can be disassembled from Valve, by removing the mounting studs/bolts.

Installation, Operation and Maintenance Manual

DOC.IOM.EF.EN Rev. 6

September 2015

43

Appendix

Summary of Contents for EL-O-Matic F-Series

Page 2: ......