48 Chapter 5 Parameters

EV1000 Series General Purpose Variable Speed Drive User Manual

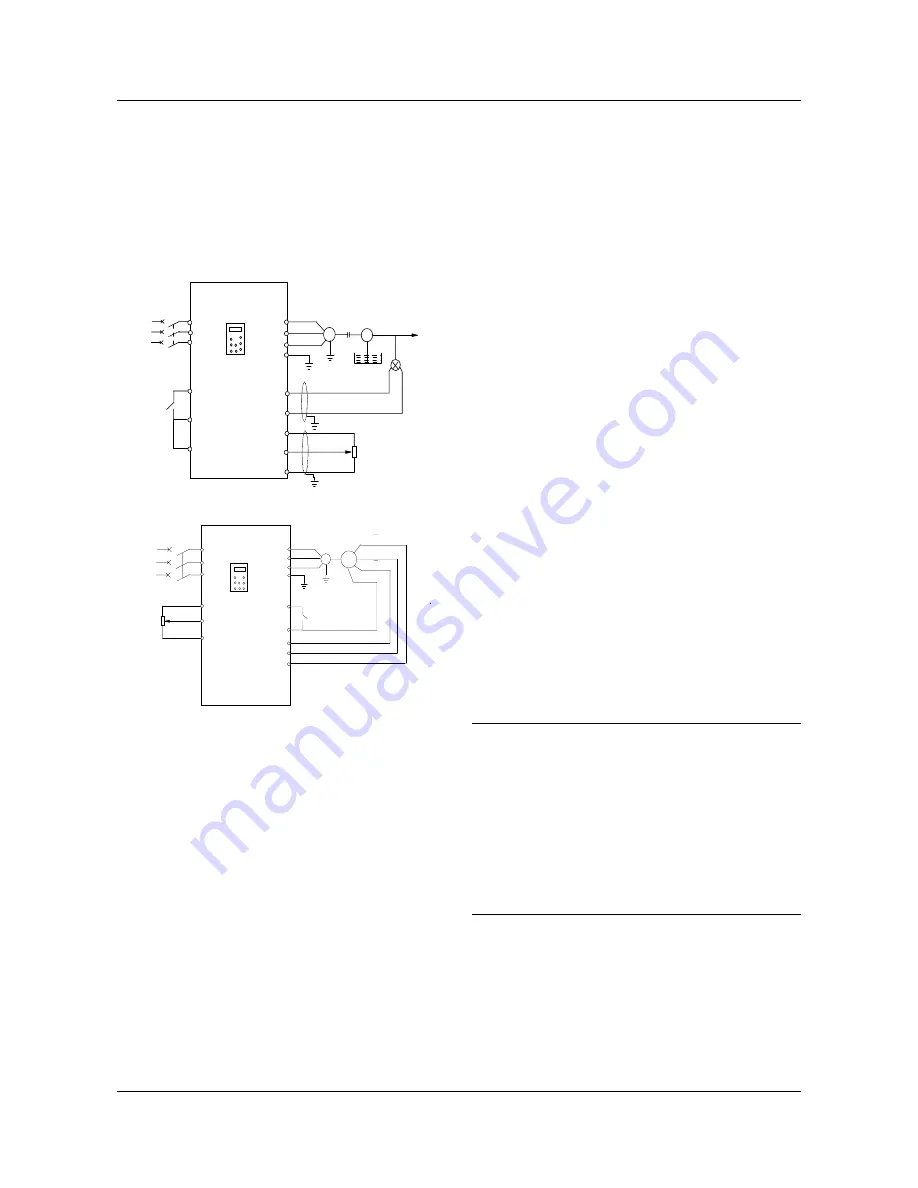

5.6 Close-loop Control (F5)

Usually, the close loop control can be divided into

two types: analog close loop and pulse close loop

according to feedback. Fig. 5-28 and Fig. 5-29

are analog and pulse close loop control wiring

diagram.

380V

EV1000

U

V

W

PE

M

P24

CCI

VRF

VCI

GND

FWD

COM

1-3K

R

S

T

P

Output

Pressure

transducer

.

GND

.

.

.

.

.

.

.

QF

Fig. 5-28 Build-in PI Analog Feedback Control

VRF

VCI

GND

1-3K

R

S

T

380V

QF

·

·

·

U

V

W

PE

M

FWD

COM

PG

A/A

B/B

PG power supply

X4

P24

X5

PG ground

·

·

·

·

·

EV1000

Fig. 5-29 PG Speed Close Loop Control System

Analog feedback control system:

An analog feedback control system can be

formed by a pressure transducer as the feedback

sensor of the internal PI.

As shown in, pressure reference (voltage signal)

is input via terminal VCI, while the feedback

pressure value is input to terminal CCI in the form

of 0~20mA current signal. The reference signal

and feedback signal are detected by the analog

channel. The start and stop of the drive can be

controlled by terminal FWD.

The above system can also use a TG (speed

measuring generator) as speed close speed-loop

control

PG speed close-loop control:

A speed close-loop control system can be formed

by external control terminals X

4

and X

5

, and pulse

generator (PG).

As shown in Fig. 5-29, close speed-loop input can

come from a potentiometer in the form of voltage

signal via terminal VCI, while the feedback value

of the close loop is input by PG in pulse mode via

terminal X4 and X5. The start and stop of the

drive can be controlled by terminal FWD.

In Fig. 5-29,

A and B are PG’s dual phase quadrature output;

P24 is connected to the power source of PG;

Speed reference is the voltage signal of 0~10V.

The voltage signal corresponds to synchronous

speed n

0

which, in turn, corresponds to 0~Max

frequency (F0.05). P is the number of poles of

motor (FH.00).

n

0

=120

×

f

max

/P

Refer to function No. 47

~

48 of F7.00~F7.04 for

the functions of input terminals X4, X5.

Note

:

1. The reference can also be input via keypad or serial

port;

2. Dual-phase input can improve the speed

measurement accuracy, while single phase input

wiring is simple;

3. Dual-phase pulse can only be input in quadrature

mode;

4. If PG is supplied from terminal P24, then the max

load current of optical PG must be less than 100mA.

The mechanism of the build-in PI is shown in the

figure below.

艾默生变频器、艾默生CT高级授权代理商--广州盟雄 020-85543394 qq:2294731312