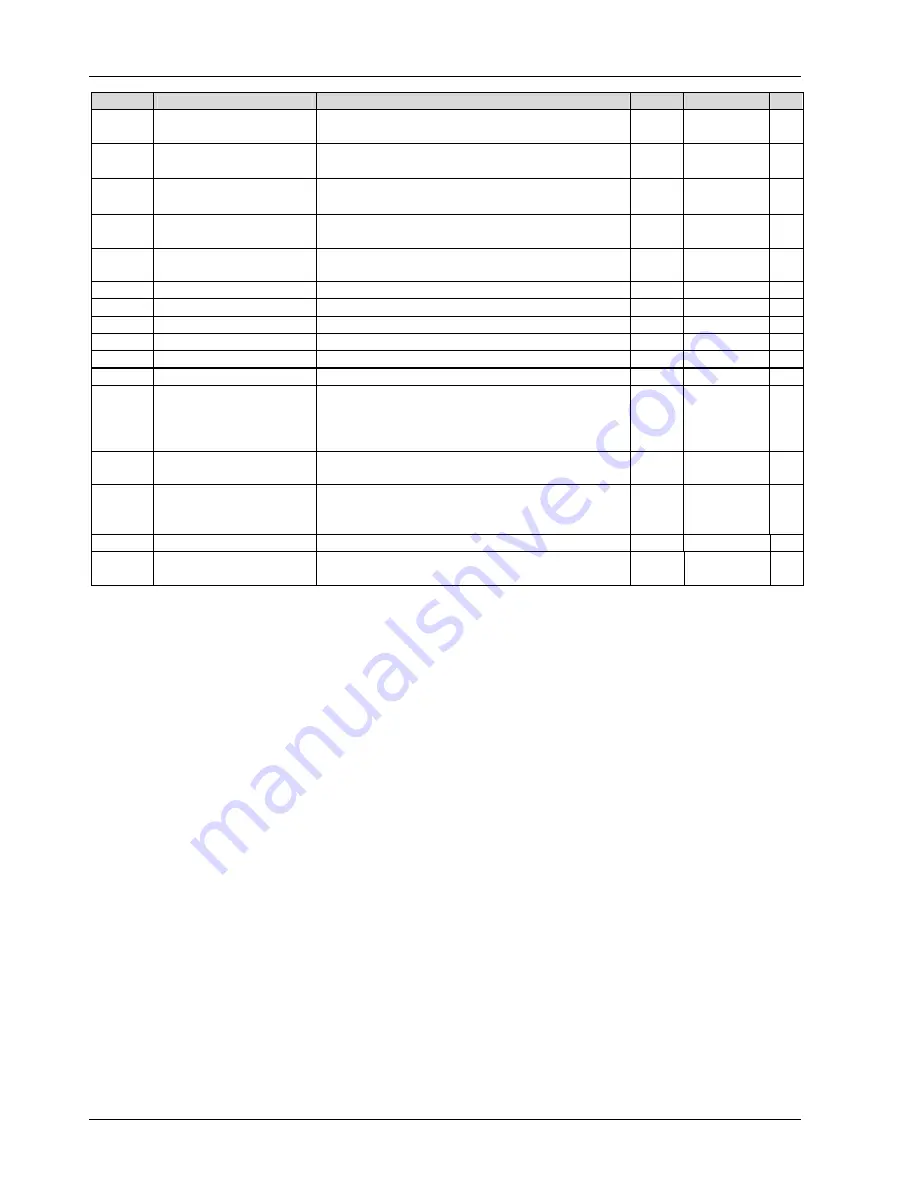

Chapter 5 Parameter Table 21

EV3200 Door Control Inverter User Manual

Parameter

Name

Setting range

Min. unit

Default

Mod.

F9.07

Frequency (Hz) at the latest

fault

0.00Hz ~ 128.00Hz

0.01Hz

0.00Hz

*

F9.08

Status of input terminal at the

latest fault

0 ~ 127 (0: OFF

;

1: ON)

CD/OD/X5/X4/X3/X2/X1

1 0

*

F9.09

Status of output terminal at the

latest fault

0 ~ 7 (0: OFF

;

1: ON)

PC3/PC2/PC1

1 0

*

F9.10

High digits of pulse counted

for door position at fault time

0 ~ 9999 (×10000)

1

0

*

F9.11

Low digits of pulse counted for

door position at fault time

0 ~ 9999

1

0

*

F9.12

High digit of OD times

0 ~ 9999 (×10000)

1

0

*

F9.13

Low digit of OD times

0 ~ 9999

1

0

*

F9.14

High digit of CD times

0 ~ 9999 (×10000)

1

0

*

F9.15

Low digit of CD times

0 ~ 9999

1

0

*

F9.16

Total operation time

0 ~ 65535 hours (max.)

1 hour

0

*

F9.17

Total running time

0 ~ 65535 hours (max)

1 hour

0

*

F9.18 Parameter

initialization

0: no operation

1: Clear the record

2: Load defaults

3 ~ 100: reserved

1

0

×

F9.19

Software version No.

1.00 ~ 99.99

0.01

Actual version

No.

-

F9.20

Product configuration No.

3200 ~ 3299

1

Actual

configuration

No.

-

F9.21

Heatsink temperature

0 ~ 100°C

1

0

*

F9.22

Relay output polarity selection

0: relays PA1/PC1 and PA2/PC2 serve as output NC relays

1: relays PA1/PC1 and PA2/PC2 serve as output NO relays

1 0

×