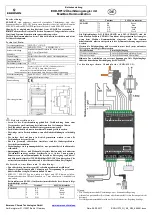

Operating instruction

EXD-HP1/2 Controller with ModBus

communication capability

Emerson Climate Technologies GmbH

Am Borsigturm 31 I 13507 Berlin I Germany

Date: 08.09.2017

EXD-HP12_OI_ML_R03_865921.docx

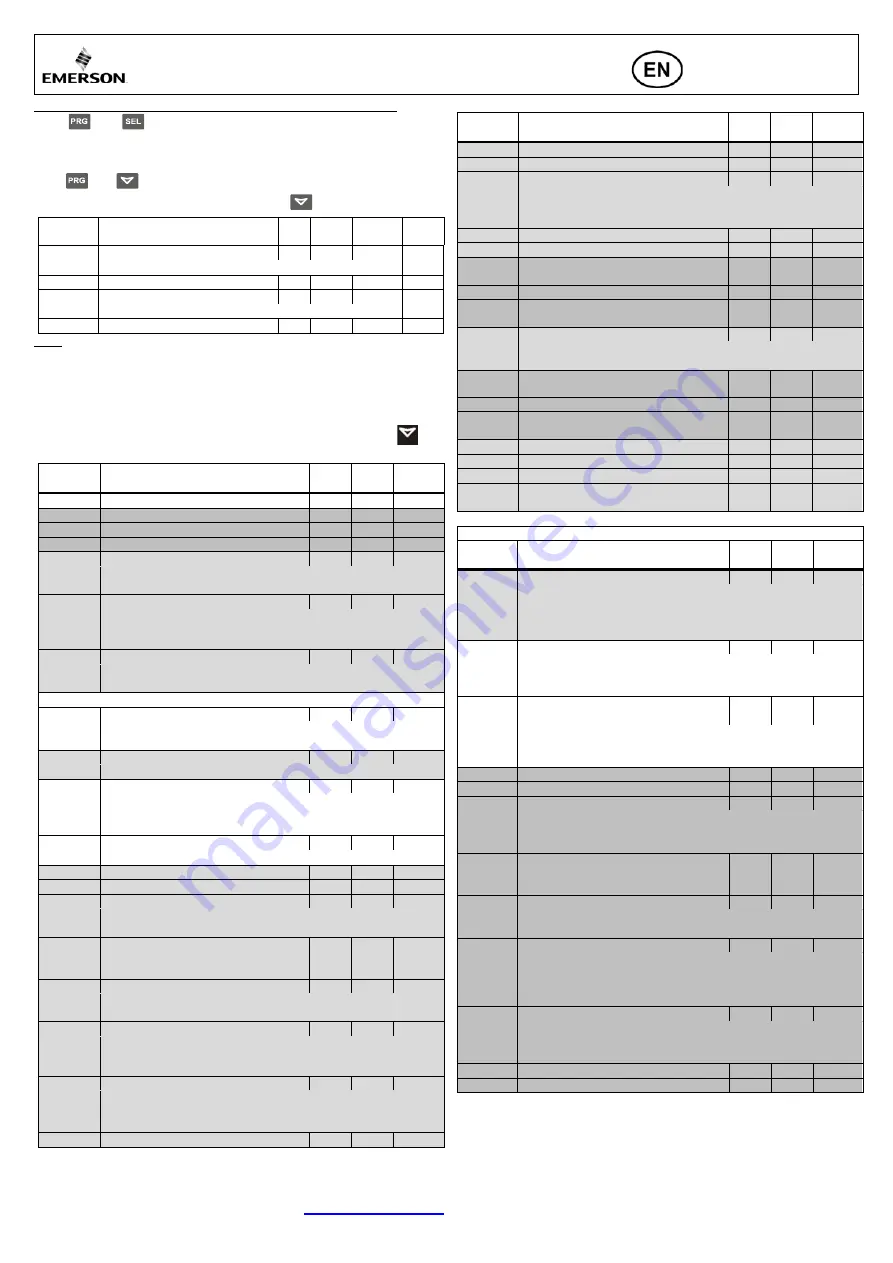

Manual alarm reset/clearing functional alarms (except hardware errors):

Press

and

together for 5 seconds. When the clearing is done, “CL”

message appears for 2 seconds.

M a n u a l m o d e o p e r a t i o n

Press

and

together for 5 seconds to access to manual mode operation.

List of parameters in scrolling sequence by pressing

button

Code

Parameter description and choices

Min

Max

Factory

setting

Field

setting

1Ho

Manual mode operation; circuit 1

0

1

0

0 = off;

1 = on

1HP

Valve opening (%)

0

100

0

2Ho

Manual mode operation; circuit 2

0

1

0

0 = off

1 = on

2HP

Valve opening (%)

0

100

0

Note: During manual operation, functional alarms such as low superheat are

disabled. It is recommended to monitor the system operation when the controller

is operated manually. Manual operation is intended for service or temporary

operation of valve at a specific condition. After achieving the required operation,

set the parameter 1Ho and 2Ho at 0 so the controller automatically operates the

valve(s) according to its setpoint(s).

L i s t o f p a r a m e t e r s i n s c r o l l i n g s e q u e n c e b y p r e s s i n g

b u t t o n :

Code

Parameter description and choices

Min

Max

Factory

setting

H5

Password

1

1999

12

Adr

ModBus address

1

127

1

br

Modbus baudrate

0

1

1

PAr

Modbus parity

0

1

0

-C2

Circuit 2 of EXD-HP2 enabled

0

1

0

0 = Enabled;

1 = Disabled

-uC

Units conversion

0

1

0

0 = °C, K, bar;

1 = F, psig

This Parameter effects only the display. Internally the units are allways SI-

based.

HP-

Display mode

0

2

1

EXD-HP1= 0 (not to display: - - -); 1(display)

EXD-HP2= 0 (not to display: - - -); 1 (circuit 1); 2 (circuit2)

Parameters Circuit 1

1uE

Function

0

1

1

0 = Superheat control (for 6 refrigerants);

1 = Economizer control (Only for R410A/R407C/R32)

1u4

Superheat control mode

0

2

0

0 = Standard;

1 = Slow

2 = fixed PID

1u0

Refrigerant

0

5

2

0 = R22;

1 = R134a;

2 = R410A;

3 = R32

4 = R407C;

5 = R290

1uP

Installed pressure sensor type

0

2

2

0 = PT5-07… 1 = PT5/6-18…

2 = PT5-30…

1uu

Start valve opening (%)

10

100

20

1u9

Start opening duration (second)

1

30

5

1uL

Low superheat alarm function

0

2

1

0 = disable (for flooded evaporator)

1 = enable auto reset

2 = enable manual reset

1u5

Superheat set-point (K)

If 1uL enabled (auto or manual)

If 1uL disabled

3

0.5

30

30

6

6

1u2

MOP function

0

1

1

0 = disable

1 = enable

1u3

MOP set-point (°C) saturation temperature

*

*

**

**): Factory setting according to selected refrigerant (u0):

+13°C for R22

+15°C for R134/R407C/R410A/R32/R290

*) Min./Max. settings dependent on selected type of refrigerant

1P9

Low pressure alarm mode circuit1

0

2

0

0 = disabled

1 = enabled auto reset

2 = enabled manual reset

1PA

Low pressure alarm cut-out circuit1

-0.8

17.7

0

Code

Parameter description and choices

Min

Max

Factory

setting

1Pb

Low pressure alarm delay circuit1

5

199

5

1Pd

Low pressure alarm cut-in circuit1

0.5

18

0.5

1P4

Freeze protection alarm function

0

2

0

0 = disabled,

1 = enabled auto-reset,

2 = enabled manual reset

1P2

Freeze alarm cut-out circuit1

-20

5

0

1P5

Freeze protection alarm delay, sec.

5

199

30

1P-

Superheat control circuit1 (Kp factor)

Display 1/10K

0.1

10

1.0

1i-

Superheat control circuit1 (Ti factor)

1

350

100

1d-

Superheat control circuit1 (Td factor)

Display 1/10K

0.1

30

3.0

1EC

Hotgas temperature sensor source

0

1

0

0 = ECP-P30

1 = Via Modbus input

1PE

Economizer control circuit1 (Kp factor)

Display 1/10K

0.1

10

2.0

1iE

Economizer control circuit1 (Ti factor)

1

350

100

1dE

Economizer control circuit1 (Td factor)

Display 1/10K

0.1

30

1.0

1uH

High superheat alarm mode circuit 1

0

1

0

1uA

High superheat alarm setpoint circuit 1

16

40

30

1ud

High superheat alarm delay circuit 1

1

15

3

1E2

Positive correction of measured Hotgas

temperature.

0

10

0

Parameters Circuit 2 (only EXD-HP2)

Code

Parameter description and choices

Min

Max

Factory

setting

2u4

Superheat control mode

0

2

0

0 = Standard;

1 = Slow;

2 = Fix PID

(For trouble shooting/no warranty if system to be operated with fix PID)

2u0

System Refrigerant

0

5

2

0 = R22;

1 = R134a;

2 = R410A;

3 = R32

4 = R407C;

5 = R290 (only with EXM/ EXL)

2uP

Installed pressure sensor type

(When DI2 is off)

0

3

1

0 = PT5-07…

1 = PT5/6-18…

2 = PT5-30…

2uu

Start valve opening (%)

10

100

20

2u9

Start opening duration (second)

1

30

5

2uL

Low superheat alarm function

0

2

1

0 = disable (for flooded evaporator)

1 = enable auto reset

2 = enable manual reset

2u5

Superheat set-point (K)

If 2uL enabled (auto or manual)

If 2uL disabled

3

0.5

30

30

6

6

2u2

MOP function

0

1

1

0 = disable

1 = enable

2u3

MOP set-point (°C) saturation temperature

*

*

**

**): Factory setting according to selected refrigerant (2u0):

+13°C for R22

+15°C for R134a/R407C/R410A/R32/R290

*) Min./Max. settings dependent on selected type of refrigerant

2P9

Low pressure alarm mode circuit 2

0

2

0

0 = disabled

1 = enabled auto reset

2 = enabled manual reset

2PA

Low pressure alarm cut-out (bar) circuit 2

-0.8

17.7

0

2Pb

Low pressure alarm delay (sec) circuit 2

5

199

5