Instruction Manual

D101329X012

1078 Actuator

June 2017

4

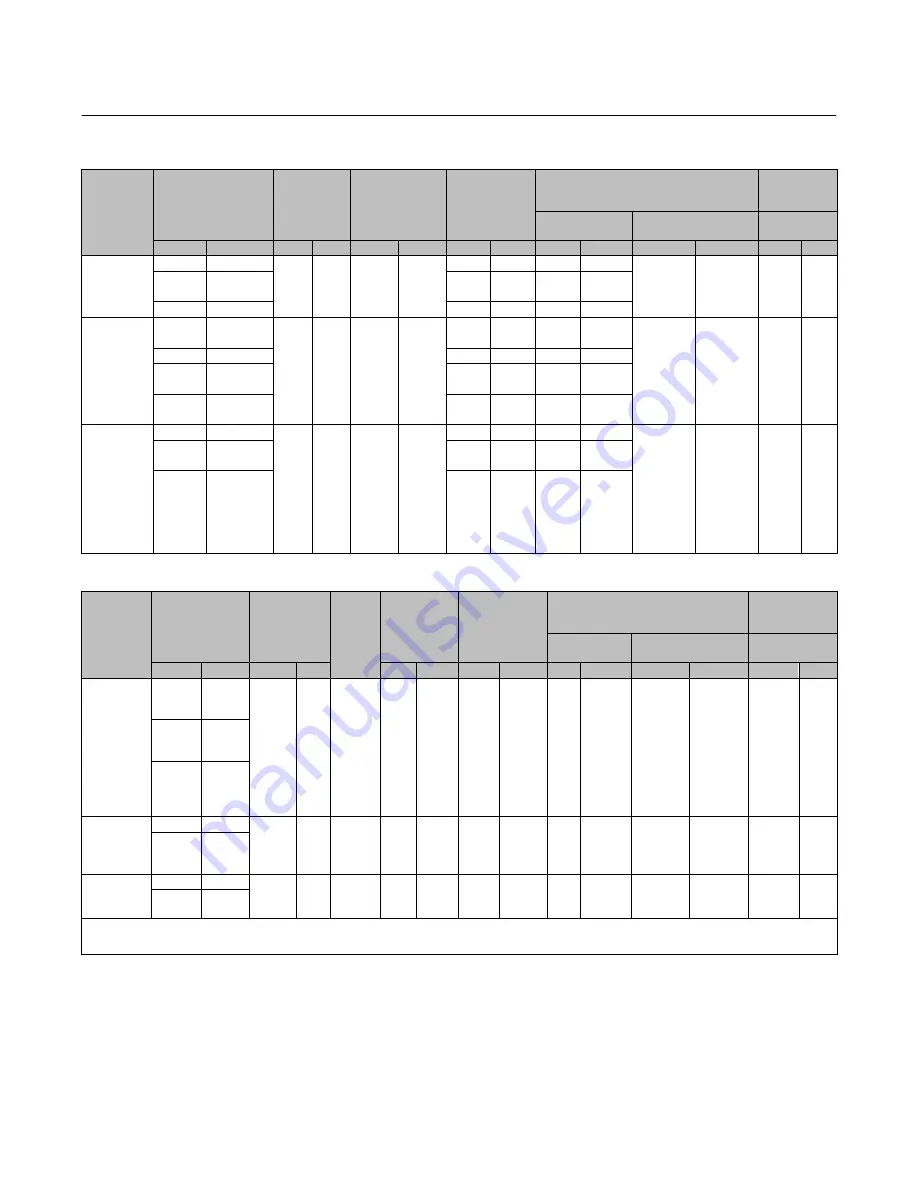

Table 2. Fisher 2052 Actuator Size Selection and Specifications for Sizes AAA, A, and C

MANUAL

ACTUATOR

SIZE

SHAFT SIZE

POWER

ACTUATOR

STANDARD

HANDWHEEL

DIAMETER

MAXIMUM

TORQUE

WHEEL‐RIM‐FORCE

HANDWHEEL

TURNS FOR

ROTATION

For Maximum

Torque

For Less Than Maximum

Torque

Degrees

mm

Inch

Type

Size

mm

Inch

N

S

m

Lbf

S

in

N

Pounds

N

Pounds

60

90

AAA

(2400 in•lbs)

12.7

1/2

2052

1

203

8

131

1156

144

32

Divide N

S

m

req'd by

0.91

Divide lbf

S

in

req'd by 36

4

6

14.2x15.9

15.9

9/16x5/8

5/8

211

1866

232

52

19.1

3/4

271

2400

298

67

A

(8000 in•lbs)

14.3x15.9

15.9

9/16x5/8

5/8

2052

2

406

16

489

4326

204

45

Divide N

S

m

req'd by 2.4

Divide lbf

S

in

req'd by 96

5.3

8

19.1

3/4

590

5221

246

54

22.2

25.4

7/8

1

818

7241

341

75

28.6x31.8

31.8

1-1/8x1-1/4

1-1/4

904

8000

377

83

C

(18000

in•lbs)

19.1

3/4

2052

3

610

24

1338

11842

279

61

Divide N

S

m

req'd by 4.8

Divide lbf

S

in

req'd by 194

9

13.5

22.2

25.4

7/8

1

1566

13862

326

71

28.6x31.8

31.8

38.1

39.7x44.5

44.5

50.8

1-1/8x1-1/4

1-1/4

1-1/2

1-9/16x1-3/4

1-3/4

2

2034

18000

424

93

Table 3. Fisher 1052 Actuator Size Selection and Specifications for Sizes 2A, 1A, B, and C

MANUAL

ACTUATOR

SIZE

(max output

torque)

SHAFT SIZE

POWER

ACTUATOR

(1)

GEAR

RATIO

HANDWHEEL

DIAMETER

MAXIMUM

TORQUE

(2)

WHEEL‐RIM‐FORCE

HANDWHEEL

TURNS FOR

ROTATION

For Maximum

Torque

For Less Than

Maximum Torque

Degrees

mm

Inch

Type

Size

mm

Inch

N

S

m

Lbf

S

in

N

Pounds

N

Pounds

60

90

1A

(8200 in•lbs)

31.8,

28.6x

31.8

1‐1/4,

1‐1/8x

1‐1/4

1052

70

32:1

610

24

929

8200

378

85

Divide N

S

m

req'd by 2.4

Divide

lbf

S

in req'd

by 96

5.3

8

38.1

31.8x

38.1

1‐1/2,

1‐1/4x

1‐1/2

(44.4,

50.8),

39.7

x44.5

(1‐3/4,

2),

1‐9/16

x1‐3/4

B

(12,000

in•lbs)

31.8

1‐1/4

1052

70

40:1

610

24

1356

12,000

369

83

Divide N

S

m

req'd by 3.6

Divide

lbf

S

in req'd

by 144

6.7

10

38.1,

(44.4,

50.8)

1‐1/2,

(1‐3/4,

2)

C

(18,000

in•lbs)

31.8

1‐1/4

1052

70

54:1

610

24

2034

18,000

414

93

Divide N

S

m

req'd by 4.8

Divide

lbf

S

in req'd

by 194

9

13.5

(44.4,

50.8)

(1‐3/4,

2)

1. Field conversion of actuators for F and G mounting adaptations requires installation of new parts.

2. Compare table value with torque requirements of the valve plus the torque required to compress the power actuator spring (from Fisher Catalog 14). Note that dynamic torque of the valve

may have a positive or negative effect on total torque required.