2

Types 1098-EGR and 1098H-EGR

pilot tYpe

outlet (coNtrol) pressure raNge

bar

psig

6351

0.21 to 1.38

0.34 to 2.41

2.41 to 6.90

3 to 20

5 to 35

35 to 100

6352

35 mbar to 0.14 bar

0.14 to 0.69

14 in. w.c. to 2 psig

2 to 10

6353

0.21 to 2.76

2.41 to 8.62

3 to 40

35 to 125

6354L

(1)

6354M

(2)

6354H

5.86 to 13.8

12.1 to 15.2

13.8 to 20.7

85 to 200

175 to 220

200 to 300

61L

61LD

61LE

17 mbar to 0.1 bar

0.07 to 0.34

0.14 to 0.69

0.34 to 1.03

0.69 to 1.38

7 in. w.c. to 2 psig

1 to 5

2 to 10

5 to 15

10 to 20

61H

0.69 to 4.48

10 to 65

61HP

1.03 to 3.10

2.41 to 6.90

6.90 to 20.7

15 to 45

35 to 100

100 to 300

Y600AM

10 to 20 mbar

17 to 40 mbar

37 to 83 mbar

0.83 to 0.17

0.17 to 0.31

0.31 to 0.48

4 to 8 in. w.c.

7 to 16 in. w.c.

15 in. w.c. to 1.2 psig

1.2 to 2.5

2.5 to 4.5

4.5 to 7

1. Without diaphragm limiter.

2. With diaphragm limiter.

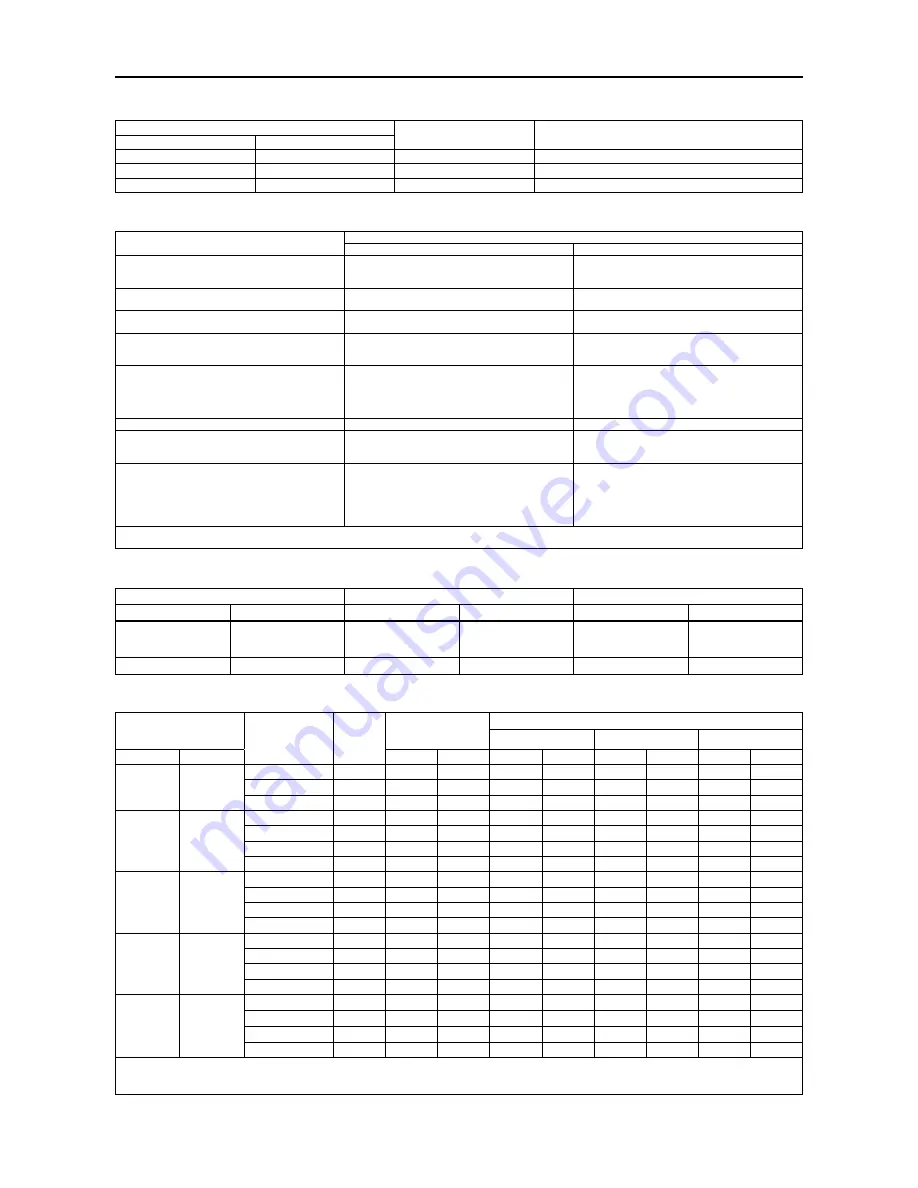

Table 2.

Outlet Pressure Ranges

actuator

outlet (coNtrol) pressure

eMergeNcY casiNg pressure

type

size

bar

psig

bar

psig

1098

30

40

(standard)

70

6.90

5.17

3.45

100

75

50

7.93

5.65

4.48

115

82

65

1098H

30

24.1

350

27.6

400

Table 3.

Actuator Sizes and Maximum Pressures

Table 4.

Maximum and Minimum Differential Pressures for Main Valve Selection

BodY size

spriNg part

NuMBer

spriNg

color

MaxiMuM alloWaBle

diFFereNtial

pressure

(1)

MiNiMuM diFFereNtial pressure required For Full stroKe

size 30 actuator

size 40 actuator

size 70 actuator

dN

Nps

bar

psig

bar

psig

bar

psig

bar

psig

25

1

14A9687X012

Green

4.1

60

0.24

3.5

0.17

2.5

0.07

1

14A9680X012

Blue

8.6

125

0.34

5

0.21

3

0.10

1.5

14A9679X012

Red

27.6

(3)

400

(3)

0.48

7

0.34

5

0.17

2.5

50

2

14A6768X012

Yellow

1.4

20

- - - -

- - - -

0.14

2

0.07

1

14A6626X012

Green

4.1

60

0.28

4

0.21

3

0.10

1.5

14A6627X012

Blue

8.6

125

0.41

6

0.34

5

0.14

2

14A6628X012

Red

27.6

(3)

400

(3)

0.76

11

0.69

10

0.21

3

80

3

14A6771X012

Yellow

1.4

20

- - - -

- - - -

0.17

2.5

0.07

1

14A6629X012

Green

4.1

60

0.34

5

0.28

4

0.14

2

14A6630X012

Blue

8.6

125

0.55

8

0.41

6

0.17

2.5

14A6631X012

Red

27.6

(3)

400

(3)

0.97

14

0.76

11

0.28

4

100

4

14A6770X012

Yellow

1.4

20

- - - -

- - - -

0.25

3.5

0.09

1.3

14A6632X012

Green

4.1

60

0.69

10

0.34

5

0.17

2.5

14A6633X012

Blue

8.6

125

0.90

13

0.55

8

0.21

3

14A6634X012

Red

27.6

(3)

400

(3)

1.5

22

0.90

13

0.34

5

150, 200 x 150

or 300 x 150

6, 8 x 6

or 12 x 6

15A2253X012

Yellow

1.4

20

- - - -

- - - -

0.42

6

0.15

2.2

14A9686X012

Green

4.1

60

0.90

13

0.66

9.5

0.28

4

14A9685X012

Blue

8.6

125

1.3

19

0.97

14

0.41

6

15A2615X012

Red

27.6

(3)

400

(3)

1.9

(2)

28

(2)

1.3

19

0.55

8

1. Maximum inlet pressure is equal to set pressure plus maximum differential.

2. Requires special 6300 Series pilot construction without integral check valve and with external Type 1806H 2.8 bar d / 40 psid check valve.

3. Should not exceed the body rating limit. Use this pressure value or the body rating limit, whichever is lower.

Table 1.

Body Sizes and End Connection Styles

BodY size

cast iroN

steel or staiNless steel

dN

Nps

25, 50

1, 2

NPT, CL125 FF or CL250 RF

NPT, CL150 RF, CL300 RF, CL600 RF, BWE, SWE or PN 16/25/40

80, 100, 150

3, 4, 6

CL125 FF or CL250 RF

CL150 RF, CL300 RF, CL600 RF, BWE or PN 16/25/40

200 x 150, 300 x 150

8 x 6, 12 x 6

- - - -

CL150 RF, CL300 RF, CL600 RF or BWE