Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

30

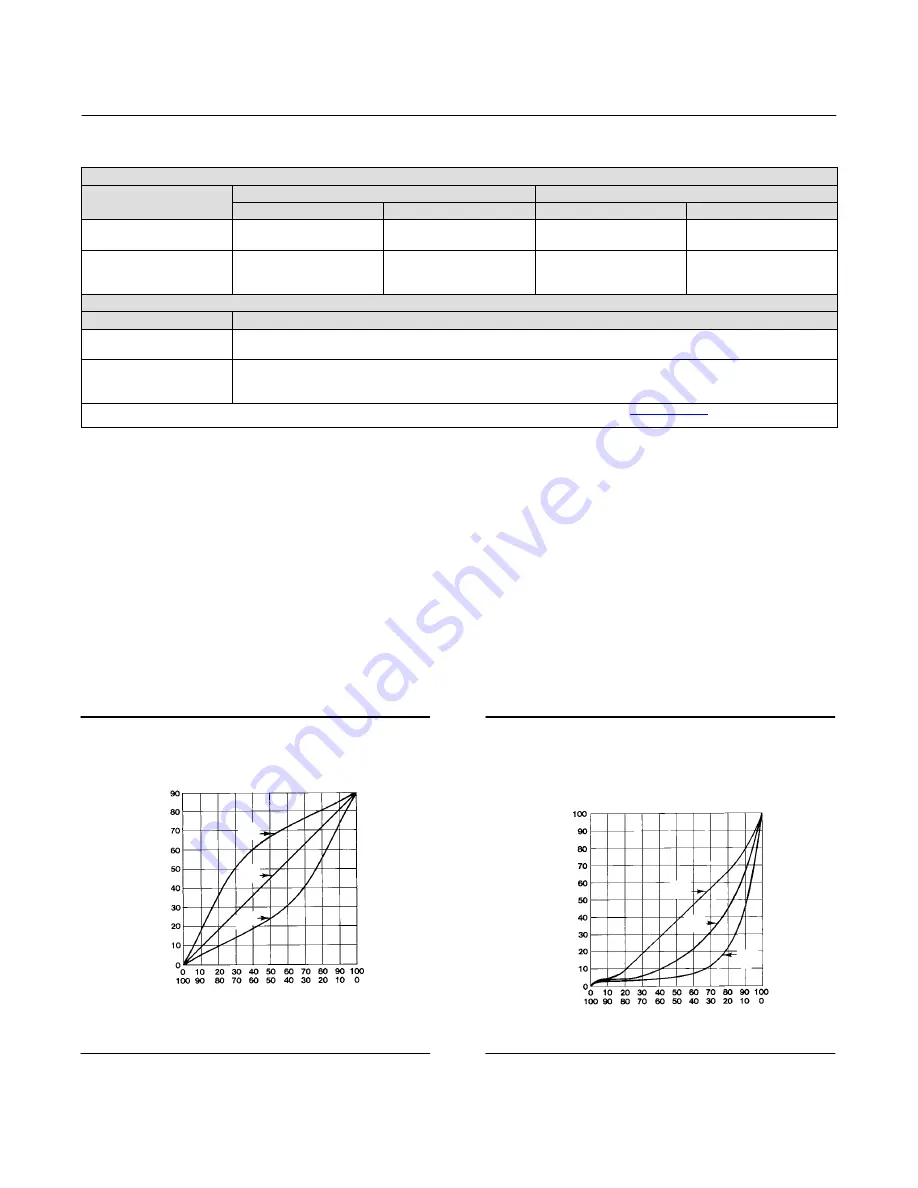

Table 12. Split‐Ranging Capabilities

3610J Positioners

Split

0.2 to 1.0 Bar or 3 to 15 Psig Input Signal

0.4 to 2.0 Bar or 6 to 30 Psig Input Signal

Bar

Psig

Bar

Psig

Two‐way

0.2 to 0.6

0.6 to 1.0

3 to 9

9 to 15

0.4 to 1.2

1.2 to 2.0

6 to 18

18 to 30

Three‐way

0.2 to 0.5

0.5 to 0.7

0.7 to 1.0

3 to 7

7 to 11

11 to 15

0.4 to 0.9

0.9 to 1.5

1.5 to 2.0

6 to 14

14 to 22

22 to 30

3620J Positioners

Split

4 to 20 Milliampere DC Input Signal

Two‐way

4 to 12

12 to 20

Three‐way

4 to 9.3

9.3 to 14.7

14.7 to 20

1. This table is only valid for the standard valve rotation or travel and range spring combinations listed in tables 8 through 11. Contact your

for input signal ranges not

listed.

Characterized Cams for 3610J, 3610JP, 3620J, and 3620JP Positioners

3610J, 3610JP, 3620J, and 3620JP positioners are available with any one of three cams: a linear cam (cam A) and two

characterized cams (cams B and C).

When the linear cam is used, there is a linear relationship between an incremental input signal change and the

resultant valve rotation. The flow characteristic is that of the control valve.

When either of the characterized cams are used, the relationship between an incremental input signal change and the

valve rotation is changed. Curves illustrating the relationship between the input signal and the valve rotation, and

between the input signal and the flow characteristic of an equal percentage valve, are shown in figures 16, 17, and 18.

Figure 16. Input Signal Versus Valve Rotation

DEGREES OF VALVE ROTATION

DIRECT

REVERSE

PERCENT OF RATED INPUT SPAN

CAM

B

CAM

A

CAM

C

A2264‐2

Figure 17. Flow Characteristics for the Various Cams

When Used With an Equal Percentage Valve

Characteristic, Push‐Down‐to‐Open Valve

DIRECT

REVERSE

PERCENT OF RATED INPUT SPAN

CAM

B

CAM

A

PERCENT OF FLOW

(PRESSURE DROP CONSTANT)

PUSH DOWN TO OPEN

33A4959‐A

A1581‐3

CAM

C