Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

37

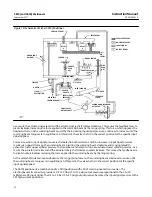

Figure 24. Schematic of Fisher 3621JP Positioner

38A6592‐A

B2147

MINOR LOOP

GAIN ADJ

ZERO ADJ

RANGE SPRING

COARSE

SPAN

ADJ

CROSS‐OVER

ADJ

RELAY BEAM

RELAY

B

RELAY

A

SUPPLY PRESSURE

NOZZLE PRESSURE

INPUT SIGNAL

OUTPUT SIGNAL

AIR

SUPPLY

FINE

SPAN

ADJ

PIVOT B

FEEDBACK

LEVER

INPUT MODULE

PIVOT A

FLAPPER

NOZZLE

FIXED

RESTRICTION

CAVITY A

CAVITY B

PISTON

ACTUATOR

SUMMING BEAM

COUNTER SPRING

FLAPPER

NOZZLE

FIXED

RESTRICTION

MAGNET

SUPPLY

COIL 4 TO

20 mA INPUT

OUTPUT SIGNAL

Disassembling the Bypass Valve

Refer to figure 26 for key number locations while disassembling the bypass valve.

1. Remove all pressure from the positioner. Disconnect the supply, instrument, and output tubing.

WARNING!

If using gas as the supply medium, ensure adequate ventilation and remove any ignition sources.

2. Remove the four socket head screws (key 169), and lift the bypass body (key 161) and bypass body gasket (key 163)

from the bypass body adaptor (key 162). Inspect the gasket and replace if necessary.

3. Remove the wire tie (key 166) and the retaining ring (key 165).

4. With a gentle pulling and turning motion, slide the bypass lever assembly (key 160) from the bypass body (key

161). Inspect the O‐rings (keys 159, 167, and 168) for nicks or wear and replace if necessary. Apply lubricant (key

153) to the O‐rings before replacement.

5. Remove the two socket head screws (key 54) and remove the bypass body adaptor (key 162) and adaptor gasket

(key 164) from the gauge block (key 158).

6. Inspect the adaptor gasket (key 164) and replace if necessary.

Disassembling the Gauge Block