Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

43

smooth zero adjustment, insert the zero adjustment screw through the zero spring bracket, and thread the zero

adjustment spring seat onto the zero adjustment screw.

10. Place the zero spring (key 141) and zero spring bracket (key 144) on the positioner input module and ensure that

the zero spring ends are centered on the seats. Ensure that the tab on the zero adjustment spring seat (key 142) is

inserted in the anti‐rotator slot in the zero spring bracket. Insert the two machine screws (key 139) through the zero

spring bracket, carefully compress the zero spring by pushing down on the zero spring bracket, and tighten the

screws in the positioner case.

Feedback Lever Assembly procedure; then, continue with steps 13 through 15 below.

number.

13. Assemble the flexure adjustment (key 156) onto the two minor loop feedback flexures. Slide the flexure adjustment

along the entire length of the flexures, making sure it does not rub against the relay at any point. If contact is made

with the relay or diaphragm edges at any point, remove the flexure adjustment, loosen the twelve machine screws

(key 47), slide the relay manifold slightly to provide clearance and tighten the machine screws (key 47). Perform

steps 2 through 5 of the Disassembling the Summing Beam Assembly procedure and loosen the two machine

screws (key 124). Perform steps 4 through 10 of the Assembling the Summing Beam Assembly procedure.

Assemble the flexure adjustment on the minor loop feedback flexures and check for clearance.

(key 55). For 3611JP and 3621JP positioners only, install the parallel flexure (key 179) with the two socket head

screws and lock washers (keys 180 and 181). The parallel flexure is not used on positioners with 585 size 100

actuators.

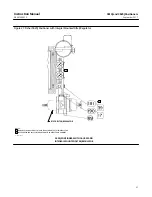

Assembling the Relay

Refer to figure 25 for key number locations while assembling the relay.

1. Replace the pressure plate gasket (key 115D) and pressure plate (key 115C) with the ten machine screws (key 115J).

Visually align the two large holes in the pressure plate with the two stainless steel pressed‐in valve seats in the

positioner case (key 115A) and tighten the machine screws.

2. Install the valve plugs (key 115G), valve plug springs (key 115H), and valve plug shrouds (key 115K) in the two relay

holes. Place the body plug gaskets (key 115F) on the body plugs (key 115E) and tighten in the positioner case.

3. If the pivot pin (key 10) was removed from the relay manifold (key 9), apply a light coat of lubricant (key 153) to the

pin and slide it into the relay manifold and relay beam assembly (key 122). Position the pivot pin so it is flush with

the left side of the relay manifold as viewed in figure 13, and tighten the two set screws (key 57). The pivot pin must

not rub against the flexure adjustment (key 156).

4. Assemble the supply relay head (key 15) and nozzle relay head (key 14) onto the relay beam assembly (key 122)

with the two machine screws (key 50), but do not tighten the screws. The nozzle relay head is the larger in diameter

of the two and is installed in the large manifold hole. Insert the nozzle relay head holder from the repair kit through

the larger manifold hole and into the nozzle relay head (key 14). Insert the supply relay head holder from the repair

kit through the smaller manifold hole and into the supply relay head (key 15). Tighten the two machine screws

(key 50). Remove the nozzle relay head holder and supply relay head holder from the manifold. The nozzle relay

head (key 14) and supply relay head (key 15) are now correctly aligned in the center of the manifold holes.

5. Dimple the relay nozzle diaphragm (key 8) and relay supply diaphragm (key 7). Place both diaphragms in the

positioner case (key 115A) with the fabric side of the diaphragms showing and align the diaphragm holes with the

mounting holes in the positioner case.

6. Carefully place the relay manifold/beam assembly over the relay diaphragms. Ensure the relay diaphragms are lying

flat and the diaphragm edges are not doubled over. Ensure that the diaphragm convolutions are centered in the

relay manifold holes and are not pinched. The relay beam assembly (key 122) flexure must be on top of the

summing beam assembly (key 123) flexure as shown in figure 14).

7. Install the twelve relay manifold machine screws (key 47), but do not tighten them.

8. If the summing beam assembly (key 123) is removed, perform the Assembling the Summing Beam Assembly

procedure, steps 1 through 12. Then, continue with steps 9 through 11 below.