Instruction Manual

D200149X012

3610J and 3620J Positioners

September 2017

45

2. Install gauges (key 43), pipe plugs (key 37), or tire valves (key 41, not shown) as applicable to the converter. Apply

sealant (key 39) to the threads of the gauges, pipe plugs or tire valves.

3. If the converter module was removed from the pneumatic positioner, apply lubricant (key 17) to the O‐ring (key 26)

and insert the converter module into the housing.

4. Replace the two screws (key 30) and tighten them.

5. If other positioner components are removed, refer to the appropriate reassembly procedures and assemble the

positioner completely.

6. Connect the supply tubing, output tubing, and conduit to the converter.

7. Connect the wiring to the terminal block by using installation procedures.

a. If an internal grounding wire is used inside the housing compartment, connect the wire to the housing ground

screw (key 31) and replace the cap (key 20).

b. If an exterior grounding wire is used, connect the grounding wire to the exterior ground screw (key 31).

8. Plug relay A and relay B output connections and apply 2.4 bar (35 psig) to the supply pressure connection. Apply a

20 milliampere DC input signal to the converter.

9. Check for leaks using a soap solution or other solution compatible with nitrile; check the O‐rings (key 36) and any

other components which were disassembled or disconnected.

10. If the converter module was replaced, calibrate the pneumatic portion of the positioner by performing the

procedures in the Calibration section. There is no converter module calibration.

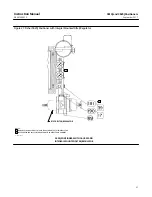

Assembling the Feedback Lever Assembly

Refer to figure 28 for key number locations while assembling the feedback lever assembly.

1. Press the two flange bearings (key 37) into the pillow blocks (key 35) if removed.

2. Assemble the mandrel (key 148), the spacer (key 149), the spring (key 70), and the pillow blocks (key 35) onto the

feedback lever assembly (key 117) and install the E‐ring (key 61). For 3610J, 3610JP, 3620J, and 3620JP positioners

only, assemble the roller (key 39) and follower post (key 38) onto the feedback lever assembly and tighten the hex

nut (key 60).

153) and insert the span adjustment screw into the feedback lever assembly (key 117) and thread into the spring

hanger (key 130,figure 25). Ensure the tip of the span adjustment screw is in the guide hole and install the retaining

ring (key 129, figure 25).

pillow blocks (key 35) with the four machine screws (key 43).

for the correct summing beam hole number.

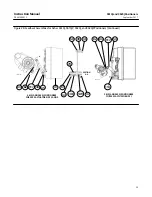

Assembling the Bypass Valve Assembly

Refer to figure 26 for key number locations while assembling the bypass valve assembly.

1. If the gauge block (key 158) is removed, perform the Assembling the Gauge Block procedure.

2. Assemble the adaptor gasket (key 164) and bypass body adaptor (key 162) onto the gauge block (key 158) and

tighten the two socket head screws (key 54).

3. Apply lubricant (key 153) to the O‐rings (keys 159, 167, and 168) sparingly and install the O‐rings on the bypass

lever assembly (key 160). The two center O‐rings are retained in the bypass lever assembly by applying a slight twist

to the O‐ring with the thumb and first finger while pushing the O‐ring into place.

4. Install the bypass lever assembly (key 160) into the bypass body (key 161) with a gentle twisting and pushing

motion to reduce the chance of nicking an O‐ring.