Instruction Manual

D101728X012

3710 and 3720 Positioners

September 2017

17

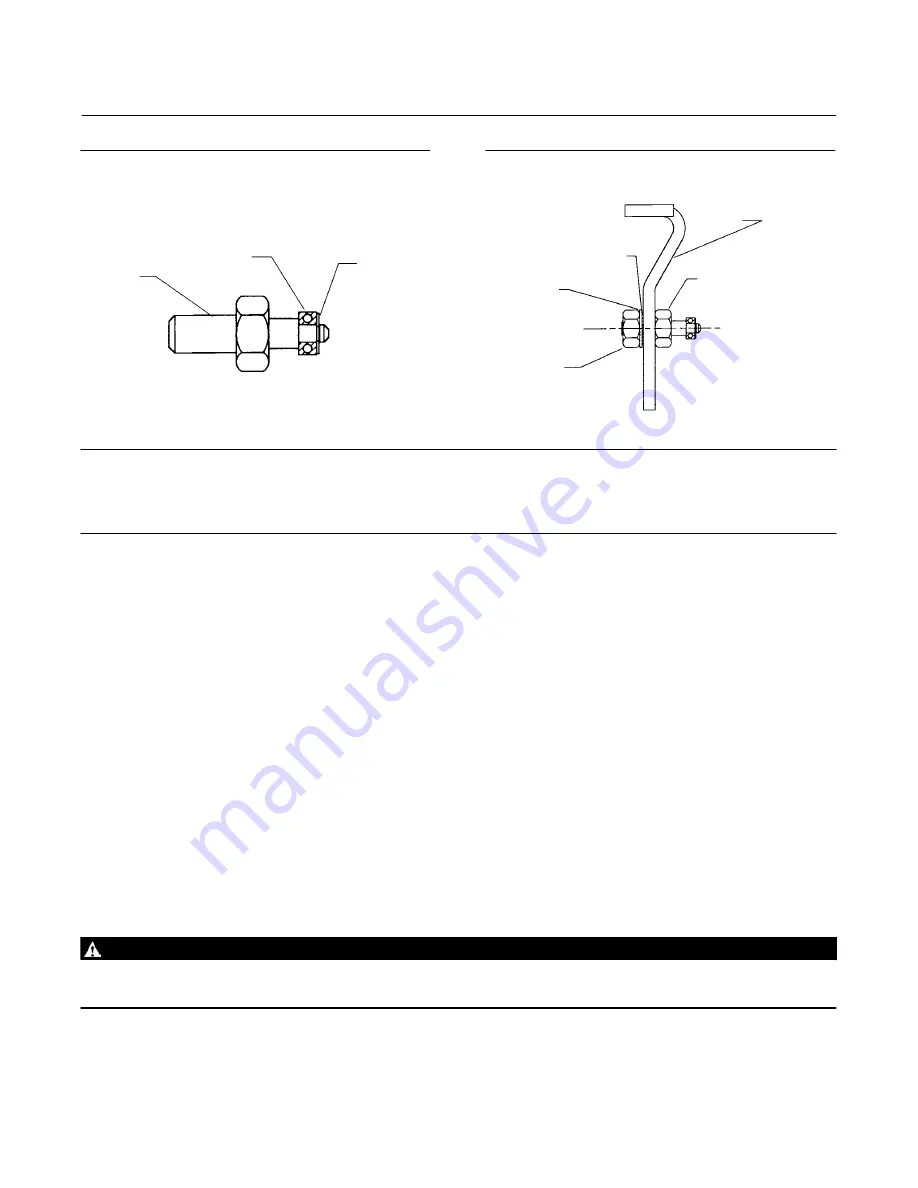

Figure 8. Drive Stud and Roller Bearing Assembly

DRIVE STUD

(KEY 95)

ROLLER BEARING

(KEY 101)

E‐RING

(KEY 102)

Figure 9. Drive Stud Bracket with Drive Stud and

Roller Bearing Assembly

FLAT WASHER

(KEY 1103)

HEX NUT

(KEY 96)

LOCK

WASHER

(KEY 100)

DRIVE STUD

AND ROLLER BEARING

DRIVE STUD BRACKET

(KEY 98)

Note

Before performing the next step, position the valve plug stem at the lower end of its travel. Position the actuator stem at the upper

travel stop. Check for sufficient clearance between the actuator stem and the valve stem to allow removing the stem bracket

assembly. If there is insufficient clearance, remove the actuator from the valve.

5. Loosen the stem bracket retainer (key 14) and let it slide down over the valve plug stem. Remove the stem bracket

assembly (key 13).

6. Install the stem bracket assembly (with drive stud and drive stud bracket) on the actuator stem. Align the stem

bracket assembly so that it will be parallel with the back yoke cover. Install the stem bracket retainer and tighten to

68 N

S

m (50 lbf

S

ft). If the actuator was removed from the valve, install the actuator on the valve. Do not attach the

stem connector at this time.

7. Attach the mounting bearing (key 97) to the mounting plate (key 43) with three hex socket cap screws (key 93).

8. Refer to the actuator instruction manual. Loosen the four screws, and remove the actuator blanking plate.

cap screws (key 45) and lock washers (key 92).

10. Loosen the four captive cover screws and remove the positioner cover.

11. Loosen the cam locknut (key 37, figure 31).

12. Attach the positioner to the mounting plate with three hex socket cap screws (key 46). Make sure that the

13. Attach the feedback lever (key 94) to the end of the feedback shaft with the two hex socket cap screws (key 93).

The markings on the feedback lever should be visible when looking toward the back of the positioner. Make sure the

roller bearing (key 101) on the drive stud engages the slot in the feedback lever.

WARNING

An unexpected change in actuator supply pressure while performing the following steps could result in personal injury. Use

lockout procedures to ensure a stable air supply.

14. Perform the Actuator Mounting procedure steps 2 through 8 in the actuator instruction manual to reconnect the

actuator stem and valve stem.