Instruction Manual

D103292X012

C1 Controllers and Transmitters

March 2017

34

3. Do not invert the reversing block unless also changing the controller action from direct to reverse (or vice versa).

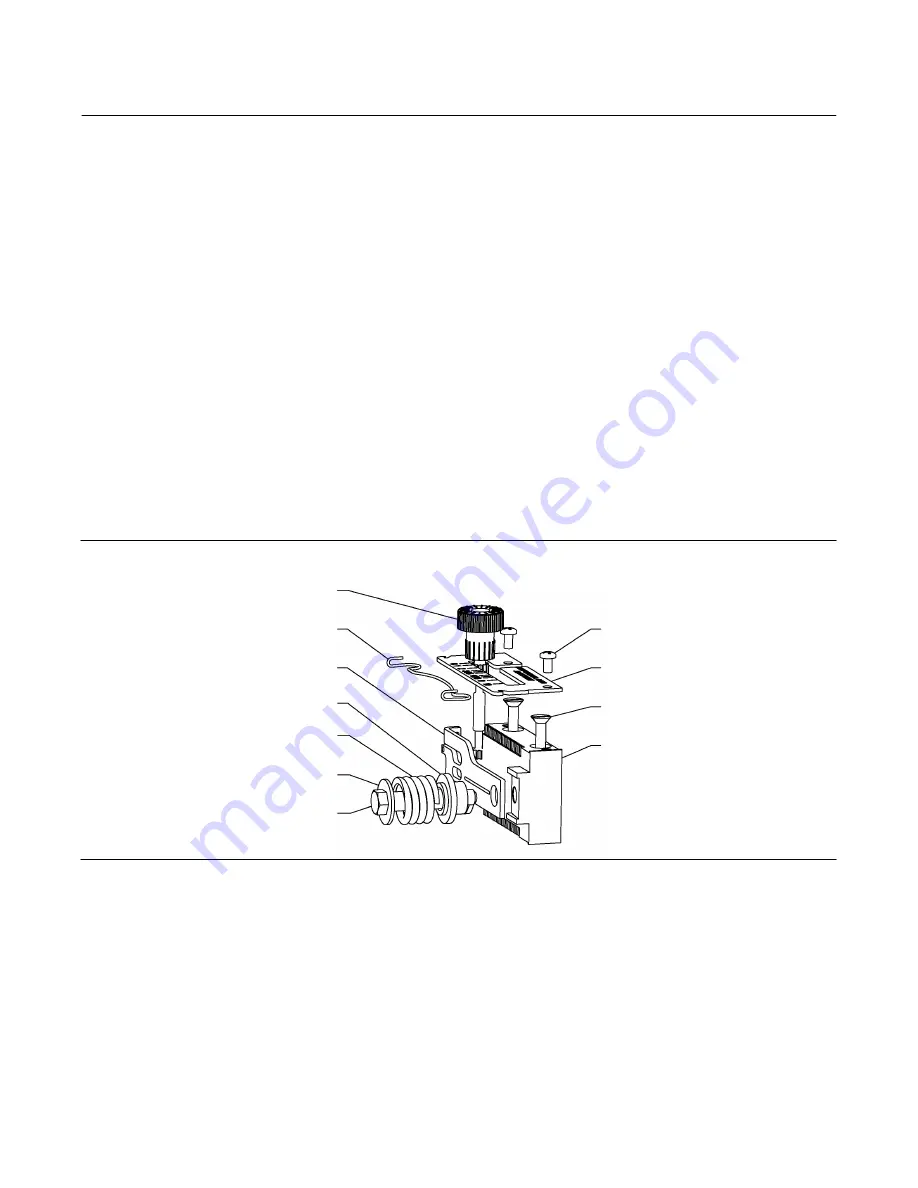

4. Invert the proportional band assembly (refer to figure 17):

a. Turn the proportional band adjustment knob (key 73) to 10.

b. Unscrew the spring adjustor (key 65), removing the bias spring (key 70) and washers (key 64) with it.

c. Unclip the lock spring (key 72). Remove the indicator scale (key 69) and proportional band adjustment knob

(key 73).

d. Remove the gain adjustment bar (key 63). Flip it over so it attaches to the opposite side of the cantilever spring

(key 8), as shown in figure 16, and screw it back down.

e. Flip over the indicator scale (key 69); install it and the proportional band adjustment knob (key 73) as a unit. Snap

in the lock spring (key 72).

f. Tighten down the spring adjustor (key 65) with the bias spring (key 70) and washers (key 64) until it stops against

the gain adjustment bar (key 63).

g. Turn the proportional band adjustment knob to the 10 setting. If it cannot be turned to the 10 setting loosen the

spring adjustor (key 63).

5. Check all connections for leaks with a soap-and-water solution. Perform the appropriate calibration procedure.

Figure 17. Proportional Band Assembly

PROPORTIONAL BAND ADJUSTMENT KNOB

(KEY 73)

LOCK SPRING

(KEY 72)

CANTILEVER SPRING

(KEY 8)

BIAS SPRING

(KEY 70)

WASHER

(KEY 64)

SPRING ADJUSTOR

(KEY 65)

GE34725-B

SPRING SPACER

(KEY 245)

MACHINE SCREW

(KEY 56)

INDICATOR SCALE

(KEY 69)

MACHINE SCREW

(KEY 74)

GAIN ADJUSTMENT BAR

(KEY 63)

Reverse to Direct Action

Use the numbered steps below to change from reverse action (increasing process pressure produces decreasing

output pressure) to direct action (increasing process pressure produces increasing output pressure), or vice versa.

Changing the action is accomplished by reversing the positions of the reversing block, proportional band assembly,

and bellows tubing(s). Refer to figures 16, 17, 18, and 21 for key number locations unless otherwise directed.

1. Isolate the controller or transmitter from process, control, and supply pressure. Vent any trapped pressure from the

controller or transmitter before proceeding with this procedure.

desired action.