Instruction Manual

D103292X012

C1 Controllers and Transmitters

March 2017

6

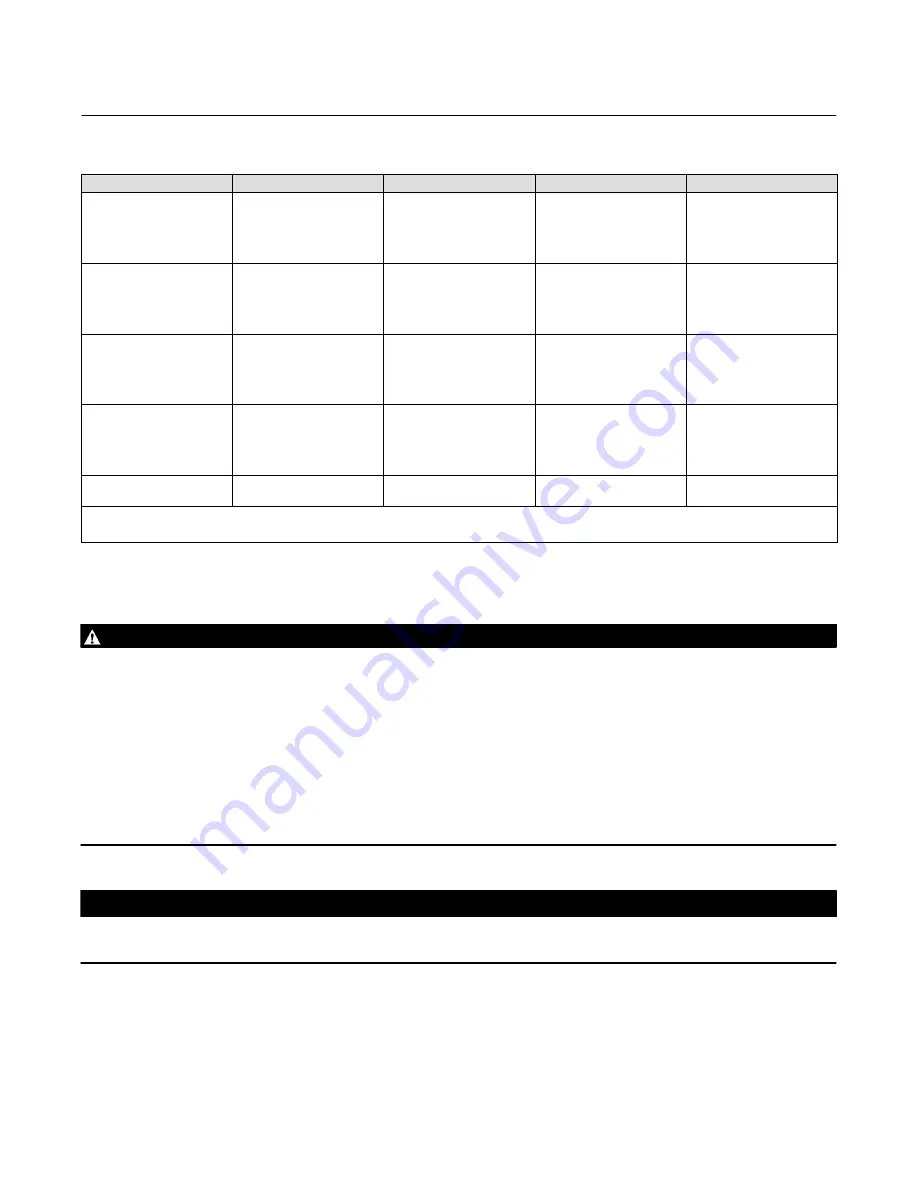

Table 6. Common Signal Pressure Conversions

Mps

kg/cm

2

bar

kPa

Psi

0.02

0.03

0.04

0.05

0.06

0.2

0.3

0.4

0.5

0.6

0.2

0.3

0.4

0.5

0.6

20

35

40

50

60

3

5

6

7

9

0.07

0.08

0.09

0.10

0.12

0.8

0.8

1.0

1.0

1.3

0.8

0.8

1.0

1.0

1.2

75

80

95

100

125

11

12

14

15

18

0.14

0.15

0.17

0.18

0.20

1.4

1.5

1.8

1.9

2.0

1.4

1.5

1.7

1.9

2.0

140

150

170

185

200

20

22

25

27

30

0.22

0.23

0.24

0.34

0.55

2.2

2.3

2.5

3.5

5.6

2.2

2.3

2.4

3.4

5.5

220

230

240

345

550

32

33

35

50

80

0.69

1.03

7.0

10.5

6.9

10.3

690

1035

100

150

1. Values as listed in ANSI/S7.4.

2. Values as listed in IEC Standard 382.

3. Values rounded to correspond with kPa values.

Installation

WARNING

To avoid personal injury or property damage resulting from the sudden release of pressure:

D

Always wear protective clothing, gloves, and eyewear when performing any installation operations.

D

Personal injury or property damage may result from fire or explosion if natural gas is used as the supply medium and

appropriate preventive measures are not taken. Preventive measures may include, but are not limited to, one or more

of the following; remote venting of the unit, re-evaluating the hazardous area classification, ensuring adequate

ventilation, and the removal of any ignition sources. For information on remote venting of this controller/ transmitter,

refer to page 11.

D

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

D

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

CAUTION

Do not use sealing tape on pneumatic connections. This instrument contains small passages that may become obstructed

by detached sealing tape. Thread sealant paste should be used to seal and lubricate pneumatic threaded connections.

Standard Installation

The instruments are normally mounted vertical with the case/cover as shown in figure 1. If installing the instrument in

any other position, be sure that the vent opening shown in figure 2 is facing downward.