S201 and S202 Series

3

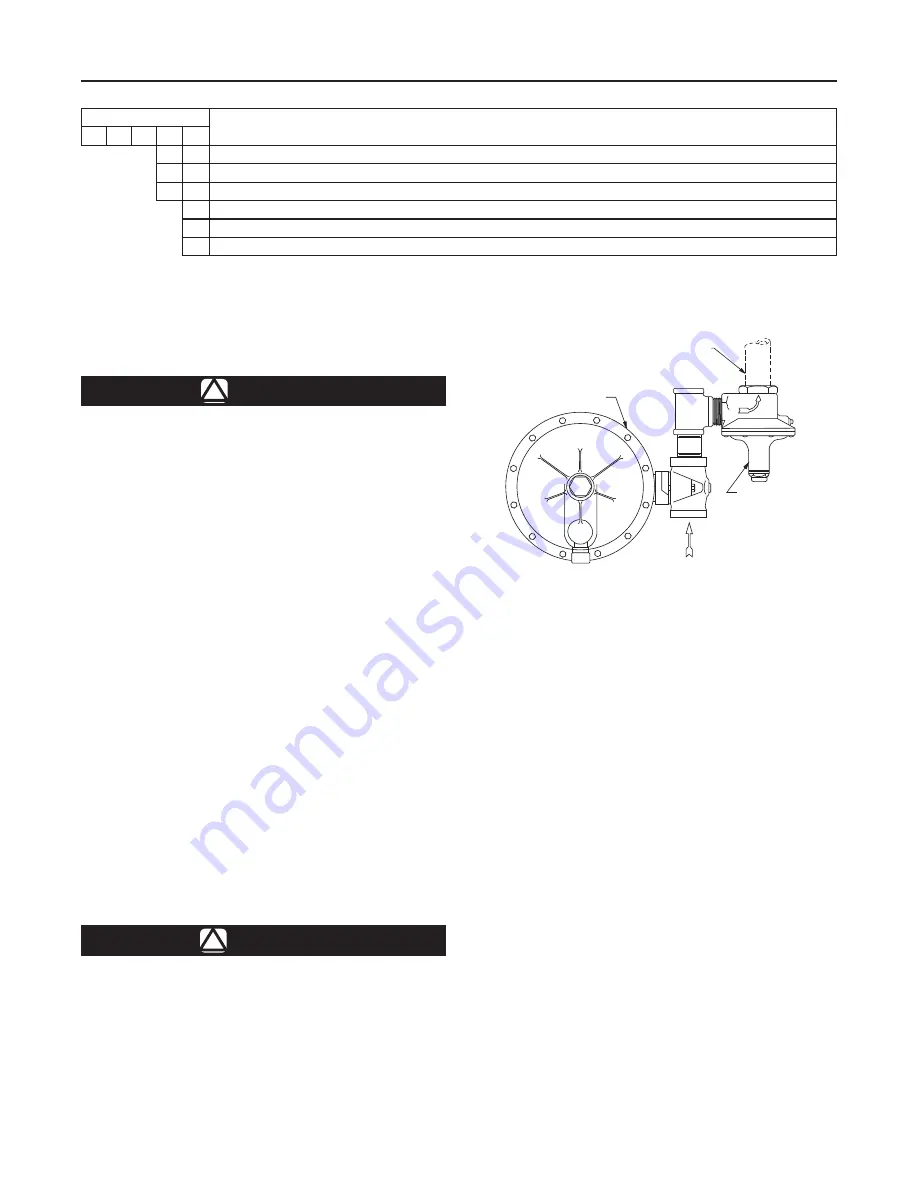

Figure 4. Type S201 Regulator Installed with the Vent

Pointed Downward and with a Type 289H Relief Valve for

High Capacity Relief

AJ4698

A1121

PROTECT vENT PIPE

WITh RAIN CAP

NPS 2 (DN 50)

TyPE 289h

RELIEF vALvE

TyPE S201

REGULATOR

TyPE NUMBER

OPTIONS

S

2

0

REGULATOR TyPE

1

Regulator, 2 to 30-inches w.c. (5 to 75 mbar) outlet range

2

Regulator, 2 to 30-inches w.c. (5 to 75 mbar) outlet range with Internal Relief

PRESSURE OUTLET RANGE

H

High-Pressure Regulator, 1 to 5 psi (0,07 to 0,34 bar) outlet range with heavy diaphragm plate

K

High-Pressure Regulator with external adjusting screw, 2 to 10 psi (0,14 to 0,69 bar) outlet range (Not an option for S202)

Figure 3. Available Configurations

Installation

!

WARNING

Personal injury or system damage

may result if this regulator is installed,

without appropriate overpressure

protection, where service conditions

could exceed the limits given on the

Specifications section and regulator

nameplate. Regulator installations

should be adequately protected from

physical damage.

All vents should be kept open to permit

free flow of gas to the atmosphere.

Protect openings against entrance of

rain, snow, insects, or any other foreign

material that may plug the vent or vent

line. On outdoor installations, point the

spring case vent downward to allow

condensate to drain (see Figure 4). This

minimizes the possibility of freezing and

of water or other foreign materials from

entering the vent and interfering with

proper operation.

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the vent should be piped away from the

regulator to the outdoors.

CAUTION

S201 and S202 Series regulators have

an outlet pressure rating lower than

their inlet pressure rating. If actual inlet

pressure can exceed the outlet pressure

rating, outlet overpressure protection

is necessary. however, overpressuring

any portion of the regulators beyond the

limits in the Specifications section and

Table 1 may cause leakage, damage to

regulator parts, or personal injury due to

bursting of pressure-containing parts.

Some type of external overpressure

protection should be provided if inlet

pressure will be high enough to damage

downstream equipment. Common

methods of external overpressure

protection include relief valves,

monitoring regulators, shutoff devices,

and series regulation.

If the regulator is exposed to an

overpressure condition, it should be

inspected for any damage that may

have occurred. Regulator operation

below these limits specified in the

Specifications section and Table 1 does

not preclude the possibility of damage

from external sources or from debris in

the pipeline.