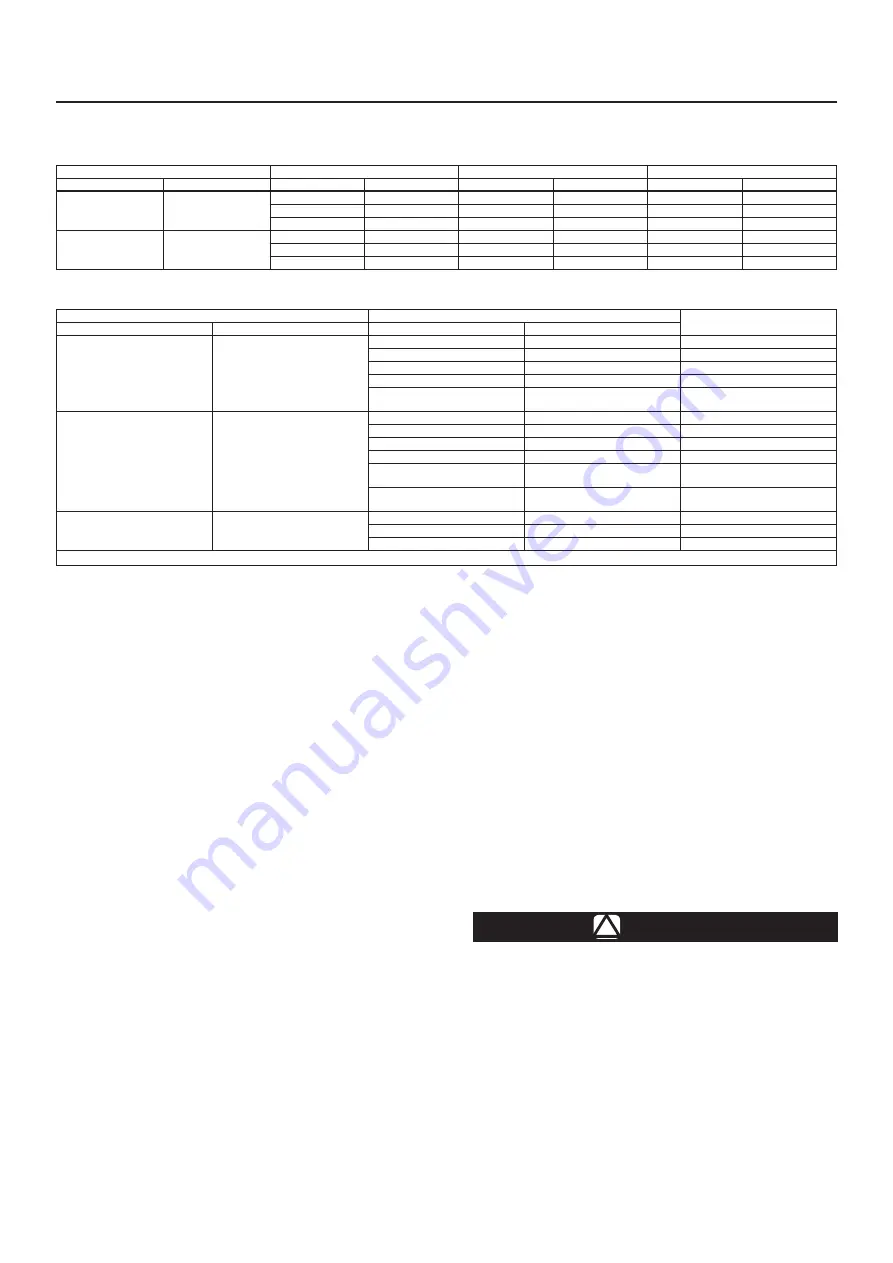

Table 1.

Maximum Operating Pressures

BODY SIZE

MAXIMUM TEMPERATURE

MAXIMUM INLET PRESSURE

MAXIMUM OUTLET PRESSURE

DN

NPS

°C

°F

bar

psig

bar

psig

15, 20, 25 and 40

1/2, 3/4, 1 and 1-1/2

65

150

14.5

210

14.5

210

135

275

12.4

180

12.4

180

204

400

11

160

11

160

50 and 80

2 and 3

65

150

10.3

150

10.3

150

135

275

8.62

125

8.62

125

204

400

7.58

110

7.58

110

Table 2.

Set Pressure Ranges and Control Spring Data

BODY SIZE

SET PRESSURE RANGE

COLOR

DN

NPS

bar

psig

15, 20

1/2, 3/4

0.2 to 0.5

(1)

2 to 8

(1)

Blue

0.4 to 1.7

5 to 25

Silver

0.7 to 3.4

10 to 50

Green

2.4 to 6.9

35 to 100

Red

5.2 to 8.6

75 to 125

Red

Yellow

25, 40 full port

40 x 25

1, 1-1/2 full port

1-1/2 x 1

0.2 to 0.5

(1)

2 to 8

(1)

Blue

0.4 to 1.7

5 to 25

Silver

1.0 to 4.8

15 to 70

Green

1.7 to 6.2

25 to 90

Red

2.4 to 6.9

35 to 100

Green

Yellow

5.2 to 8.6

75 to 125

Red

Yellow

50 and 80

2 and 3

0.7 to 1.7

10 to 25

Silver

1.0 to 3.4

15 to 50

Green

1.7 to 4.1

25 to 60

Red

1. The 0.14 to 0.55 bar / 2 to 8 psig spring is not available with the metal diaphragm.

Note

It is important that the backpressure

regulator be installed so that the vent

hole in the spring case is unobstructed

at all times.

Overpressure Protection

The recommended pressure limitations are stamped

on the nameplate.

Fisher™ backpressure regulators

are NOT ASME safety backpressure regulators.

The valve should be inspected for damage after

any overpressure condition.

Startup

The backpressure regulator is factory set at

approximately the midpoint of the spring range or the

set pressure requested, so an initial adjustment may

be required to give the desired results. With proper

installation completed, slowly open the upstream and

downstream shutoff valves.

Adjustment

To change the pressure setting, remove the closing

cap or loosen the locknut and turn the adjusting

screw or handwheel clockwise to increase pressure

or counterclockwise to decrease pressure. Monitor

the pressure with a test gauge during the adjustment.

Replace the closing cap or tighten the locknut to

maintain the desired setting.

Pressure-Loaded Construction

The spring case can be pressure loaded to adjust

set pressure. An optional tapped spring case, guide

ring seal and sealing washer on the adjusting screw

must be used for these applications. The loading

pressure is connected to the 1/4 NPT connection in

the spring case allowing registration on the spring

side of the diaphragm. Adjusting loading pressure

will proportionally change the pressure setting of the

regulator. A small amount of mechanical spring load,

in addition to the pressure load, is recommended.

Regulator set pressure achieved from the combination

of spring load and pressure load should not exceed

the set pressure ranges listed on Table 2.

Taking Out of Service (Shutdown)

!

WARNING

To avoid personal injury resulting from

sudden release of pressure, isolate

the backpressure regulator from all

pressure before attempting disassembly.

Relieve all spring compression and

isolate regulator from the pressurized

system prior to removing the clamp

(key 15, Figure 1).

Type SR8

2