BODY SIZE

OUTLET PRESSURE RANGE

COLOR

MAXIMUM DIFFERENTIAL PRESSURE

DN

NPS

bar

psig

bar d

psid

15, 20

1/2, 3/4

0.2 to 0.5

2 to 8

Blue

1.0

15

0.4 to 1.7

5 to 25

Silver

2.7

40

0.7 to 3.4

10 to 50

Green

6.9

100

2.4 to 6.9

35 to 100

Red

9.6

140

5.2 to 8.6

75 to 125

Red/Yellow

11

160

25, 40 full port

40 x 25

1, 1-1/2 full port

1-1/2 x 1

0.2 to 0.5

2 to 8

Blue

1.0

15

0.4 to 1.7

5 to 25

Silver

2.7

40

1.0 to 4.8

15 to 70

Green

6.9

100

1.7 to 6.2

25 to 90

Red

8.6

125

2.4 to 6.9

35 to 100

Green/Yellow

9.6

140

5.2 to 8.6

75 to 125

Red/Yellow

11

160

50 and 80

2 and 3

0.7 to 1.7

10 to 25

Silver

3.4

50

1.0 to 3.4

15 to 50

Green

5.2

75

1.7 to 4.1

25 to 60

Red

5.2

75

Table 3.

Maximum Differential Pressures

Table 4.

Temperature Capabilities

SEAT TYPE

DIAPHRAGM MATERIAL

O-RING MATERIAL

TEMPERATURE RANGE

°C

°F

Metal

(Stainless Steel)

Ethylene Propylene (EPDM)

EPDM

-28 to 135

-20 to 275

SST

Polytetrafluoroethylene (PTFE)/Fluorocarbon (FKM)

(1)

-6 to 204

20 to 400

PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

-6 to 204

20 to 400

Soft

(PTFE/Stainless Steel)

EPDM

EPDM

-28 to 65

-20 to 150

SST

PTFE/Fluorocarbon (FKM)

(1)

-6 to 65

20 to 150

PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

-6 to 65

20 to 150

Soft

(Polyether Ether Ketone

(PEEK)/Stainless Steel)

EPDM

EPDM

-28 to 135

-20 to 275

SST

PTFE/Fluorocarbon (FKM)

(1)

-6 to 204

20 to 400

PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM)

-6 to 204

20 to 400

1. O-ring material is PTFE for the DN 15 and 20 / NPS 1/2 and 3/4 sizes. Temperature range is the same.

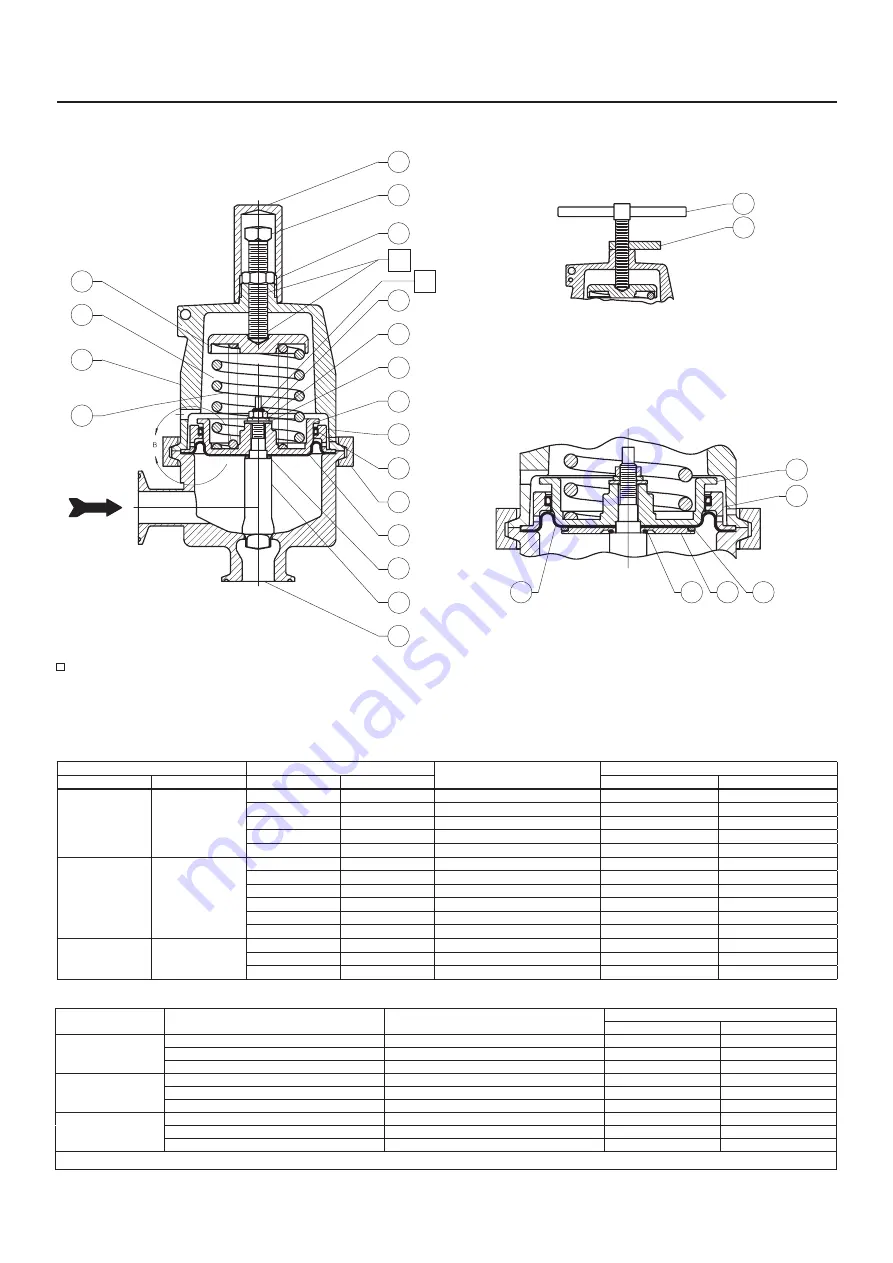

STANDARD BACKPRESSURE REGULATOR

WITH ELASTOMERIC DIAPHRAGM

19

18

17

L

11

12

14

13

16

24

23

15

8

9

5

7

3

2

1

S1

T-HANDLE OPTION

18

22

VACUUM PROTECTION OPTION

7

3

10

4

8

9

Figure 1.

Type SR8 Sanitary Regulator Assembly Drawing

APPLY LUBRICANT (L) AND SEALANT (S)

(1)

:

L = ANTI-SEIZE LUBRICANT

S1 = THREADLOCKER MEDIUM/HIGH STRENGTH SEALANT

1. Lubricant and sealant must be selected such that they meet the temperature requirements.

Type SR8

3