1. The pressure limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

II 1 G Ex h IIC T6 Ga

II 2 G Ex h IIC T6 Gb

II 1 G Ex h ia IIC T5 Ga

Specifications

The Specifications section lists the specifications for the Enardo 2000 and Enardo 2500 Series. Specification is stamped

on the nameplate attached to the emergency relief vent. Refer to Product Identification and Marking section for the

nameplate details.

Connection Sizes Available

See Table 1

Pressure Ranges

(1)(2)

Enardo 2000 Series:

2.0 to 32.0 oz./sq. in.

(0.5 oz./sq. in. increments)

3.5 to 55.0 in. w.c.

(1.0 in. w.c. increments)

8.6 to 138 mbar

(2.2 mbar increments)

Enardo 2500 Series:

4.0. to 16.0 oz./sq. in.

(0.5 oz./sq. in. increments)

7.0 to 27.0 in. w.c.

(0.5 in. w.c. increments)

17.4 to 67.2 mbar

(2.2 mbar increments)

Vacuum Pressure Ranges

(1)

(2500 Series)

0.5, 0.75, 1 and 2 oz./sq. in.

Construction Materials

Enardo 2000 Series

Base and Arm:

Carbon Steel, 304 Stainless steel and

316 Stainless steel

Disk and Seal Support:

Aluminum,

304 Stainless steel and 316 Stainless steel

Seal:

Buna-N, FEP Teflon

®

and Viton

®

Enardo 2500 Series

Base, Arm and Hood:

Carbon steel,

304 Stainless steel and 316 Stainless steel

Disk and Seal Support

: Aluminum and 316 Stainless steel

Seal:

FEP Teflon

®

, Viton

®

and Buna-N

Vacuum Spring:

302 Stainless steel

Vacuum Pallet and Vacuum Seat:

Polyphenylene Sulfide

and 316 Stainless steel

Certification

EN IEC 60079-0:2018

EN IEC 60079-11:2012

EN ISO 80079-36:2016

EN ISO 80079-37:2016

OUTER HOUSING OF STAINLESS STEEL,

CARBON STEEL OR COATED ALUMINUM

OUTER HOUSING OF UNCOATED ALUMINUM

SMART WIRELESS ID MARKING

(ENARDO 2000 SERIES MODELS ONLY)

HAZARDOUS LOCATION

Figure 4.

Product Identification and Marking

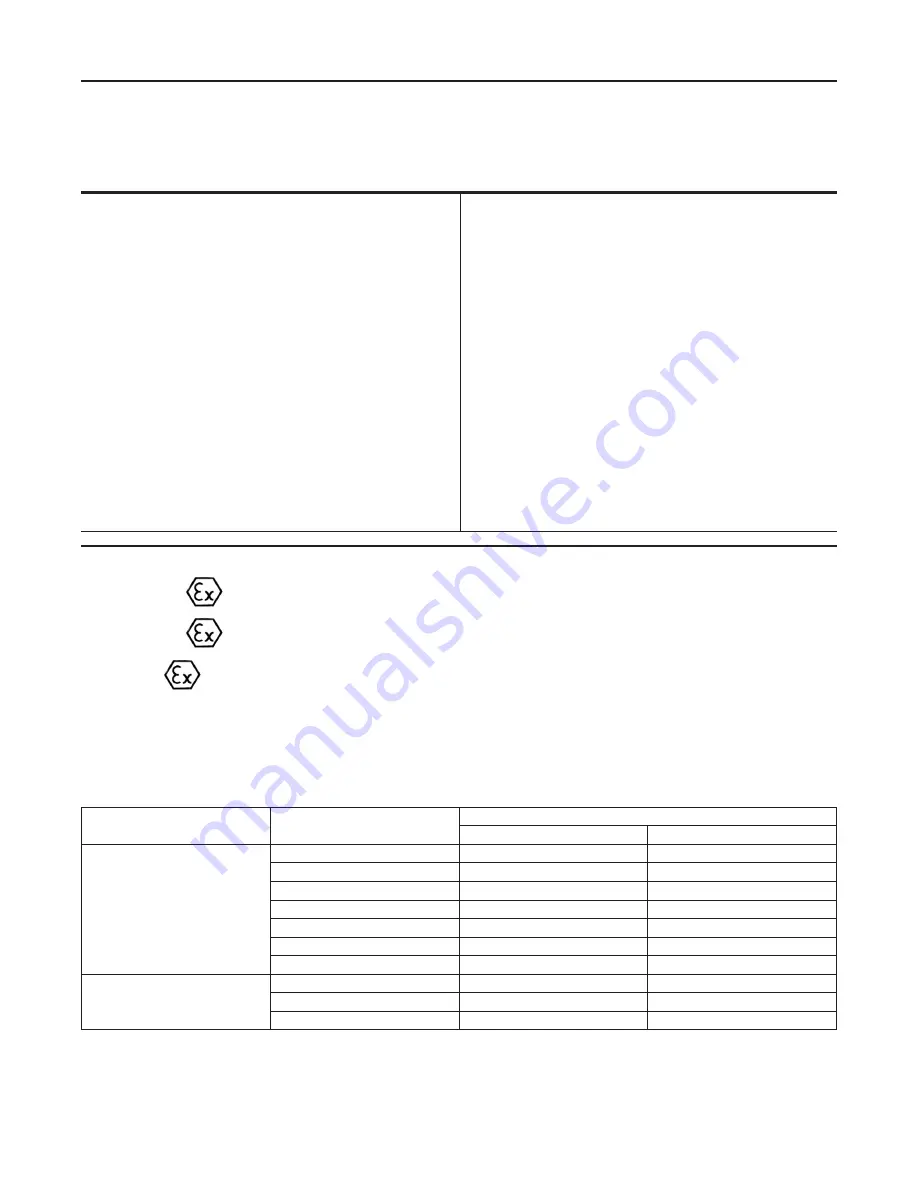

Table 1.

Connection sizes and Model Number

SERIES

MODEL

CONNECTION SIZE

ANSI

API

Enardo 2000 Series

Emergency Pressure Relief -

For Pressure Relief Only

2004

4 in.

- - - -

2008

8 in.

8 in.

2012

12 in.

- - - -

2016

16 in.

- - - -

2018

18 in.

- - - -

2020

20 in.

20 in.

2024

24 in.

24 in.

Enardo 2500 Series

Emergency Pressure Relief Vent

with Vacuum -

For Pressure and Vacuum Relief

2516

16 in.

- - - -

2520

20 in.

20 in.

2524

24 in.

24 in.

Teflon

®

and Viton

®

are marks owned by E. I. du Pont de Nemours and Company.

2

Enardo 2000 and Enardo 2500 Series

Outside North

America Only