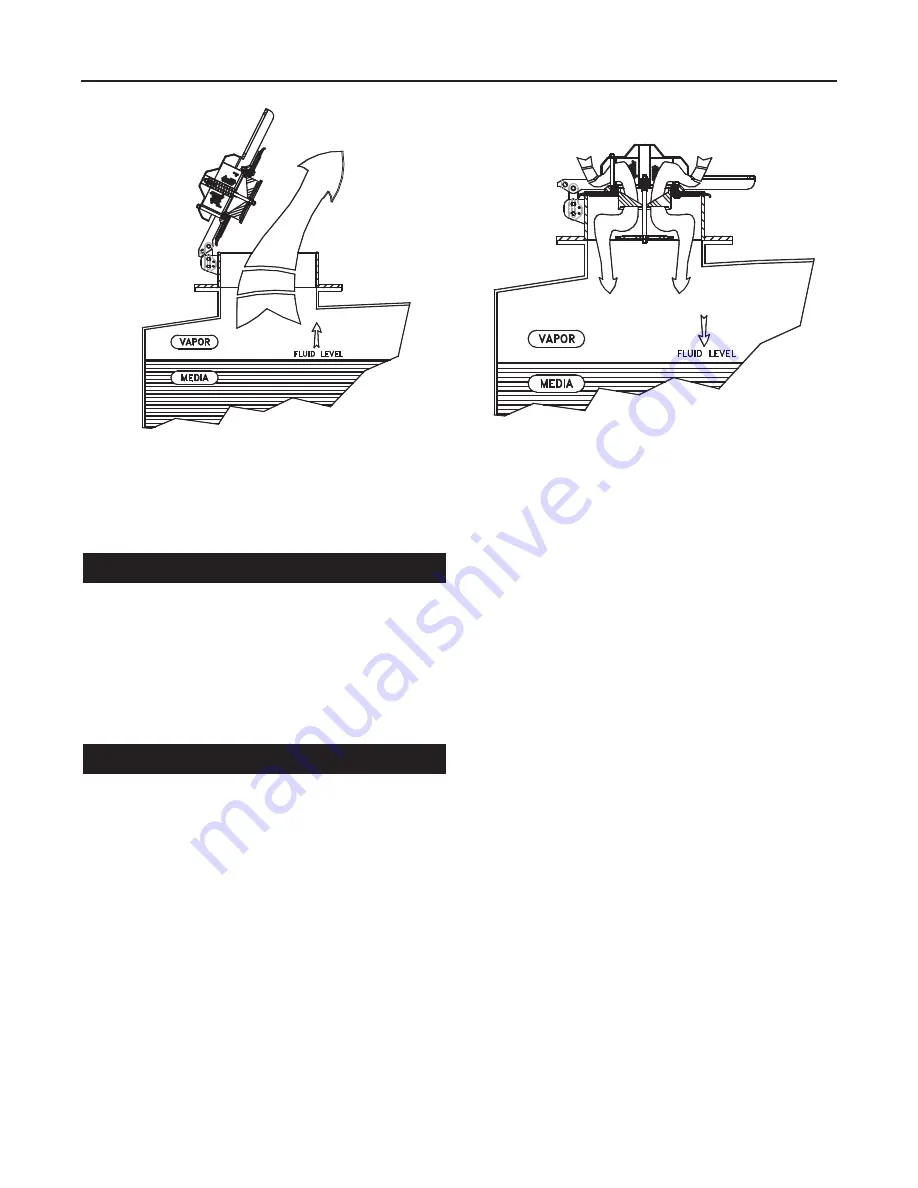

PRESSURE FLOW

VACUUM FLOW

Figure 6.

Pressure and Vacuum Flow

PPE Warning

▲

WARNING

Wear protective gloves and clothing to prevent

skin contact when handling lead weights. Wear

eye protection. Avoid breathing dust/fumes/

mist/vapors/spray. Do not eat, drink or smoke

while using the product. Avoid release to the

environment. Wash hands with soap and water

after handling. Keep away from excessive heat

and open flames.

▲

WARNING

Make sure line is free of hazardous vapors

before installing or servicing the valve.

Principle of Operation

Refer to Figure 6. The Enardo 2000 and Enardo 2500 Series

maintain a tight seal until system pressure or vacuum

exceeds the set pressure of the vent. To adjust the set

pressure, a series of weights may be stacked onto the lid

assembly. When overpressure occurs, the weighted lid

assembly lifts, breaking the seal between the seat and

seal portion of the lid assembly. This allows vapors to pass

through the vent orifice and relieve pressure build up. The

vent reseals upon relief and remains sealed.

Remote Monitoring Option

The Smart Wireless option for the Enardo 2000 Series

consists of the EPRV, a proximity sensor, and a wireless

transmitter. The built-in proximity sensor detects the open

or closed position using a magnetic target located on the

arm assembly on the hinged end. A signal is sent to the

wireless transmitter, which can then be sent to a control

room via any WirelessHART

®

Gateway. This wireless sensor

networking technology is based on the Highly Addressable

Remote Transducer (HART

®

) protocol. It is the most widely

used wireless networking standard used today and, for

this reason, the Enardo 2000 Series has been designed

to integrate with it. As long as the wireless gateway is

WirelessHART

®

, it will receive the Open or Closed signal

from the device. The WirelessHART

®

gateway will then send

the information to a control room which can make use of any

number of software integration packages.

HART

®

and WirelessHART

®

are marks owned by FieldComm Group.

It is important to note that relieving vapors near the set

pressure in a continuous manner may cause the lid

assembly to flutter or oscillate. This is a common occurrence

in products of this type in the industry. Operating the vent

with flutter or oscillation over time may cause premature

vent damage or wear. Contact your local Sales Office for

additional assistance.

4

Enardo 2000 and Enardo 2500 Series

Outside North

America Only