ENARDO 2000 SERIES EMERGENCY PRESSURE RELIEF VENT (EPRV)

ENARDO 2500 SERIES EMERGENCY RELIEF VENT WITH VACUUM (EPRV-V)

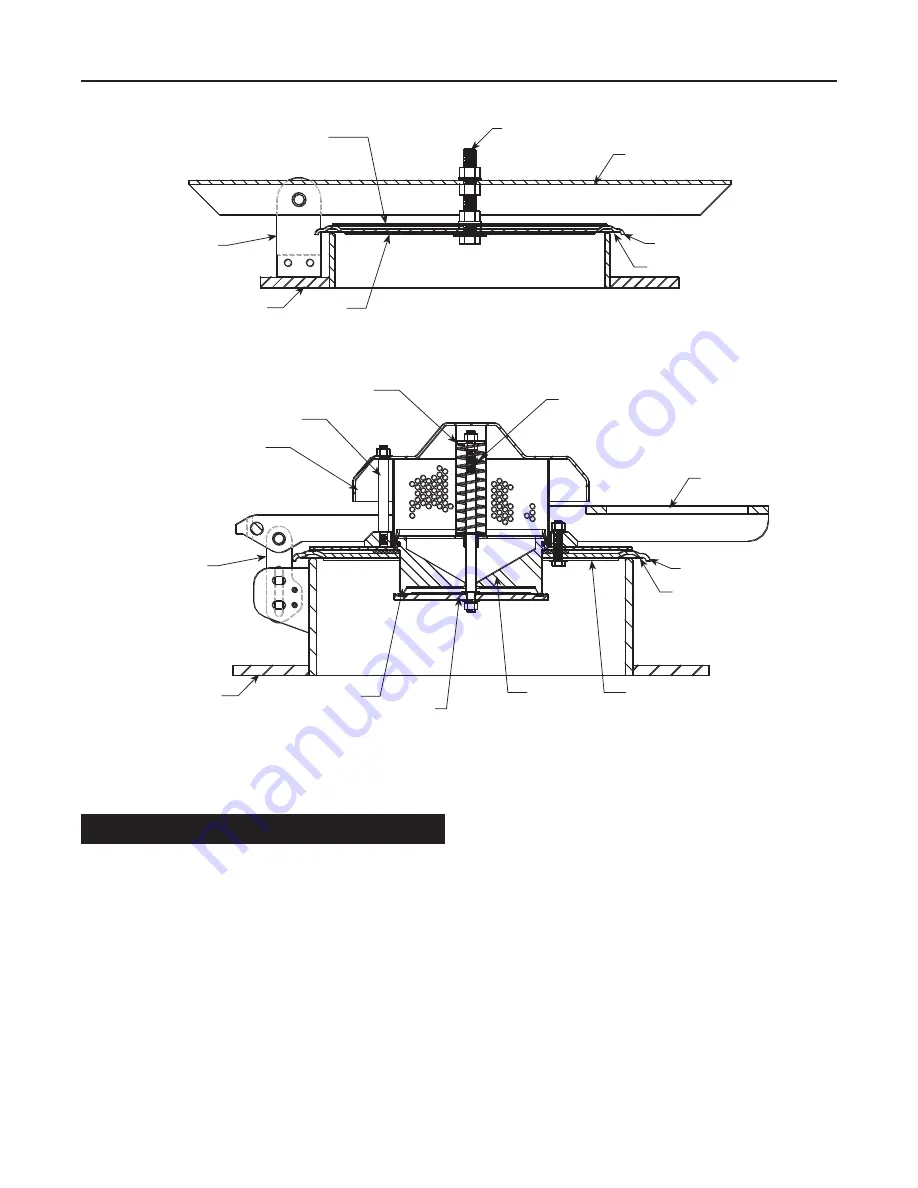

HINGE EAR

REINFORCEMENT DISK

CENTER BOLT

ARM

VENT COVER

PRESSURE SEAL

SEAL

SUPPORT

BASE

ASSEMBLY

GUIDE SLEEVE

VACUUM SPRING

VENT ROD

WEATHER

HOOD

HINGE

BASE

ASSEMBLY

VACUUM

SEAL

VACUUM

PALLET

VACUUM

SEAT

SEAL

SUPPORT

PRESSURE SEAL

VENT COVER

ARM

Figure 7.

Enardo 2000 and Enardo 2500 Series Assembly Drawing

Installation

▲

WARNING

The EPRV Series is shipped with its lid held

partially open. The lid assembly has attached

weights and is heavy. Use caution when

removing the shipping blocks and metal bands

to avoid injury to fingers and hands.

Before installing the relief vent, remove the unit from its

crate and discard any protective coverings. Follow the

instruction below for the installation of the Enardo 2000 and

Enardo 2500 Series.

Install the Enardo 2000 and Enardo 2500 Series on the

flange bolt patterns that match with bolt pattern of the vent.

The attachment flange base should be at level surface.

1. Carefully remove the Enardo 2000 and Enardo 2500

Series from its crate. The seal portion of the vents is

delicate, protect this surface while handling the unit.

2.

Place the appropriate gasket on the level attachment flange

and center the vent into place.

3. Insert the appropriate number of bolts and make sure the

vent is fastened securely. Installed bolts should be clear of

the lid assembly when it is in the full open position.

4. Inspect the installed unit from items that would keep it

from working properly. The sealing area should be free of

any debris that would cause leakage. The arm of the vent

should be able to fully open.

5

Enardo 2000 and Enardo 2500 Series

Outside North

America Only