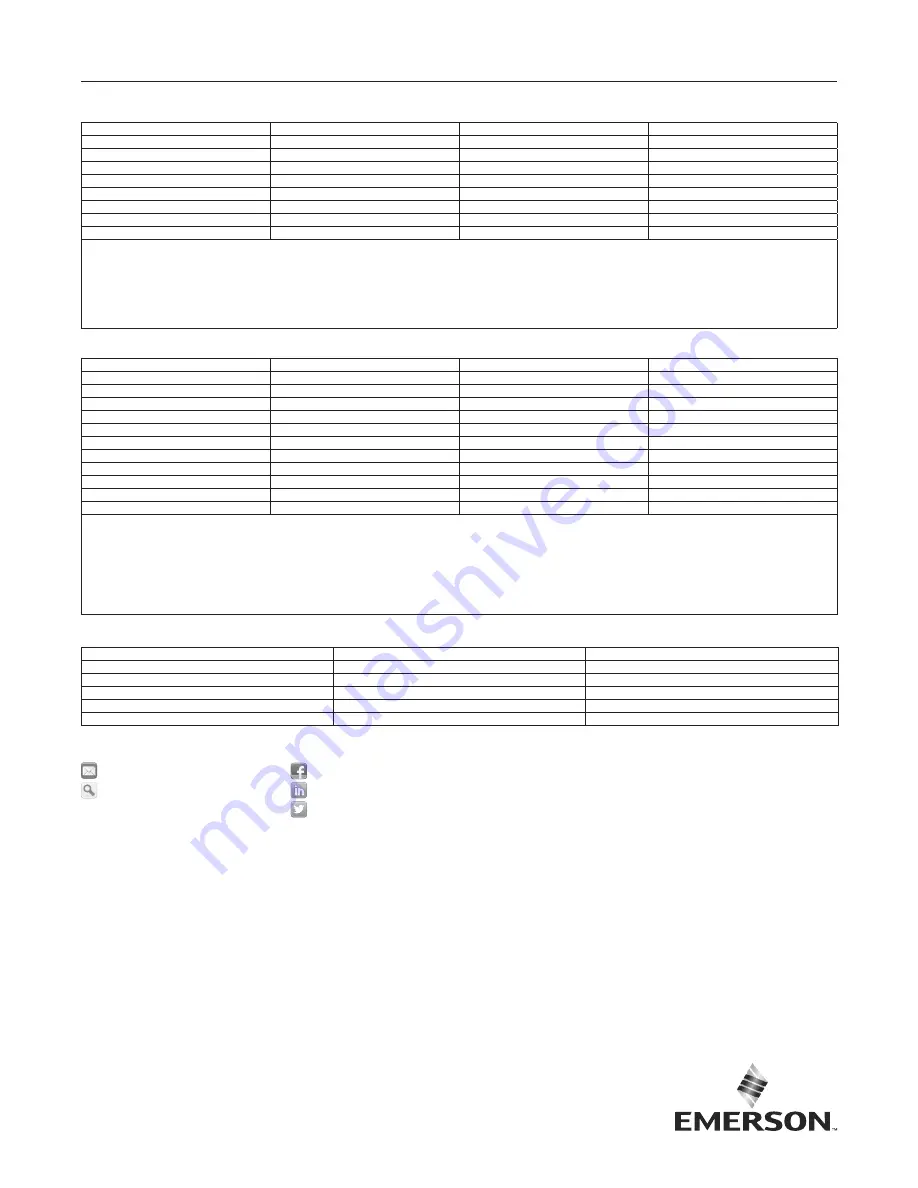

Table 2.

Torque Specifications - Raised Face Flange, Steel only

NOMINAL PIPE DIAMETER

# BOLTS

BOLT DIAMETER, IN.

TORQUE, FT-LBS.

4

8

0.63

43

8

8

0.75

109

10

12

0.88

101

12

12

0.88

135

16

16

1.00

159

18

16

1.13

244

20

20

1.13

214

24

24

1.25

253

Assumptions:

Use of SAE grade 5 bolts or studs or stronger

No lubricant

Compressed mineral fiber material or similar

Notes:

If lubricant is used on bolts, apply torque reduction factor listed in Lubricant Table.

For best results hardened steel washers should be used on all cast flange bolted connections.

Table 3.

Torque Specifications - Flat Face Flange, Steel or Aluminum

NOMINAL PIPE DIAMETER

# BOLTS

BOLT DIAMETER, IN.

TORQUE, FT-LBS.

4

8

0.63

32

8

8

0.75

68

10

12

0.88

69

12

12

0.88

98

16

16

1.00

125

18

16

1.13

142

20

20

1.13

135

24

24

1.25

156

8 API

16

0.50

20

20 API

16

0.63

75

24 API

20

0.63

75

Assumptions:

Use of SAE grade 5 bolts or studs or stronger

No lubricant

Elastomer <70 Durometer Shore A

Notes:

Flat faced flanges should never be mated to a raised face flange for installation.

If lubricant is used on bolts, apply torque reduction factor listed in Lubricant Table.

For best results hardened steel washers should be used on all cast flange bolted connections.

Table 4.

Torque Reduction Factor per Lubricant

DESCRIPTION

COEFFICIENT OF FRICTION

MULTIPLY TORQUE VALUE IN TABLE BY

Machine Oil

f = 0.15

0.75

API SA2 Grease

f = 0.12

0.60

Nickel-based Lubricant

f = 0.11

0.55

Copper-based Lubricant

f = 0.10

0.50

Heavy-duty Lubricating Past

f = 0.06

0.30

D103818X012 © 2015, 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 12/21.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a business

of Emerson Automation Solutions.

The contents of this publication are presented for informational purposes

only, and while every effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice.

Emerson Process Management Regulator Technologies Tulsa, LLC does

not assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of

any Emerson Process Management Regulator Technologies Tulsa, LLC

product remains solely with the purchaser.

Enardo 2000 and Enardo 2500 Series

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Webadmin.Regulators@emerson.com

Fisher.com

Outside North

America Only

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Tulsa, OK 74146 USA

T +1 918 662 6161

Europe

Bologna 40013, Italy

T +39 051 419 0611

Asia Pacific

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100