InSinkErator is a business unit of Emerson Electric Co.

The Emerson logo is a

trademark and a service mark

of Emerson Electric Co.

4700 21st STREET

RACINE, WI 53406

TEL: 800-845-8345

FAX: 262 554-3620

www.insinkerator.com/foodservice

InSinkErator ©2016 Printed in USA

PROJECT:

ITEM

NO.:

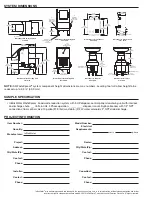

MOUNTINGS

#6 Collar Adapter Kit – ideal for welding into

trough or sink, provides 6-5/8" (168.3 mm)

opening, includes permanent splash baffle

#7 Collar Adaptor Kit – ideal for welding into

sink, provides 6-5/8” (168.3 mm) opening,

includes removable splash baffle and stopper

18" Type A Sink Bowl Assembly – bowl with

two (2) water nozzles, includes removable

splash baffle and stainless bowl cover

A complete collection of our product drawings is available

for download at the

InSinkErator Revit/CAD

Library, which

can be found at www.insinkerator.com/foodservice. Product

information is also accessible on

The KCL CADalog

. More

information is available from KCL at www.kclcad.com.

FOOD WASTE REDUCTION SYSTEM

PRODUCT FEATURES & SPECIFICATIONS

REDUCES FOOD WASTE VOLUME

• System grinds kitchen waste, presses out water, and expels semi-dry, finely-ground particles

into a 10-gallon (37.9 liter) waste bin

• Processes 100% organic waste for compost, or a mixture of food waste with up to 50% disposables

• Dewatered pulp can be disposed of into a waste or compost receptacle

• Heavy-duty 5 HP WX500 disposer processes both liquid and solid kitchen waste

• Capacity: 700 lbs. (317.5 kg) of waste per hour

• Water consumption varies by application: 2-3 GPM (7.6-11.4 LPM)

for bowl or 5 GPM (18.9 LPM) for trough

SYSTEM OVERVIEW

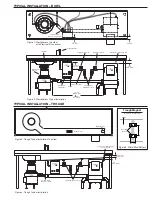

• Compact, under-table design fits under standard

table – minimum height 34" (863.6 mm)

• WX500 disposer and dewatering unit made from durable,

corrosion-resistant stainless steel construction

• NEMA 4X stainless steel electrical control box

• Safety Interlock on discharge chute

CLEANING

• Easily removable auger, auger screen, and chute – no tools required

• Quick and easy to clean –

dishwasher safe components

• Does not require cardboard

The WasteXpress

®

Food Waste Reduction System is a food waste handling solution designed to

increase productivity and profitability by reducing bulk kitchen waste by up to 85%—or ten bags of

waste to less than two. Ideal for municipalities restricting disposer use and facilities participating in

compost programs.

ELECTRICAL SPECIFICATIONS

208-230V, 60 Hz, 3 Ph, 10.3/10.8 amps,

CUL

(Disposer 8.6/8.8 amps) (Dewatering Unit 1.7/2 amps)

460V, 60 Hz, 3 Ph, 5.4 amps,

CUL

(Disposer 4.4 amps) (Dewatering Unit 1 amp)

ACCESSORIES

Additional 10 gallon (37.9 liter) Waste Bin

(all systems include one (1) waste bin)

Dejamming Wrench

Trough Nozzle - 1" (25.4 mm) NPT

Inlet/Outlet Flange - 2" (50.8 mm) NPT

(secondary, for trough or high water flow applications)

Additional Magnetic Silver Saver

(all trough systems include one (1) Magnetic Silver Saver)

PROJECT:

ITEM

NO.:

Typical installation shown. Dish table, plumbing,

and electrical connections not included.

ON-SITE

PARTS & LABOR

WARRANTY

YEAR

Form No. F483-16A-83-85