5

KEYSTONE

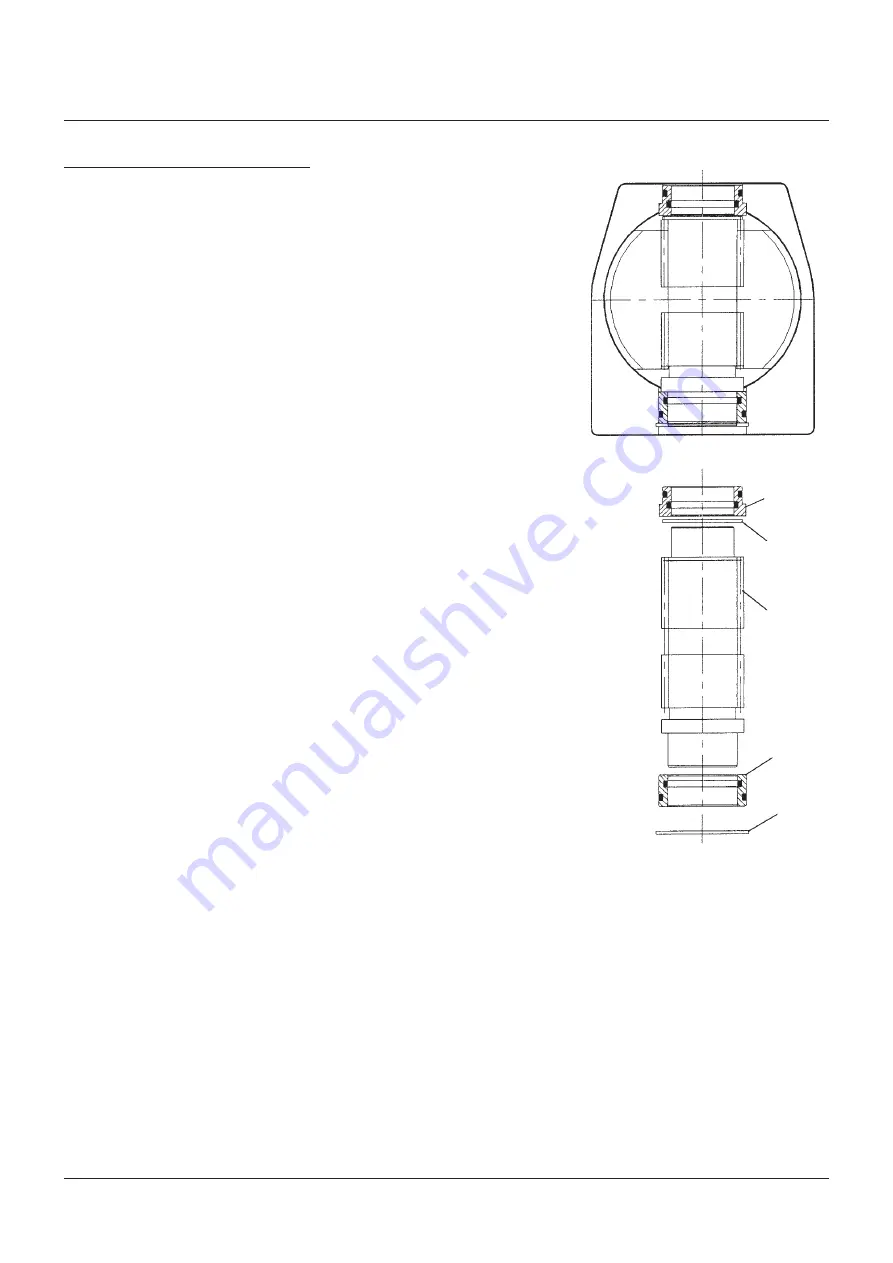

FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

NOTES

Refer to notes on page 4 as indicated.

12. Fit ‘O’-ring seals (item 14) to endcaps (item

3) using a light smear of grease.

13. Fit endcap spring assemblies to body and

alternately tighten the endcap screws

(item 15) until secure (see recommended

torque table).

14. Fit position indicator to top of actuator.

15. Operate the actuator to OPEN & CLOSE

positions using compressed air and note the

actual positions. If the required travel is not

achieved refer to page 10.

Fail Open Units

7. Insert pistons (item 2) complete with

backing pads (1) (item 18) and backing rings

(4) as follows:-

- with piston legs on

right side

of bore

(when viewed from the o-ring end of the

piston), until racks engages with pinion and

then push fully inward, the actuator is now

in the fully open position.

Note:

If no travel stops are fitted proceed to

instruction 12.

8. Turn the pinion shaft clockwise

approximately 5° until it is orientated in line

with the major axis of the actuator body. The

shaft is now in the open position.

9. Insert Open travel stop bolt (item 19/20)

together with sealing nut or lock nut (2)(3),

flat washer (2)(3) and sealing washer (2)

(3) until the bolt hits the travel stop cam.

Tighten the lock nut.

10. Turn the pinion shaft clockwise through 90°

to bring it in line with the center line of the

actuator bore, the actuator is now in the

close position.

11. Insert CLOSE travel stop bolt (item 19/20)

together with sealing nut or lock nut (2)(3),

flat washer (2)(3) and sealing washer (2)

(3) until the bolt hits the travel stop cam.

Tighten the lock nut.

Fail Close Units

7. Insert pistons (item 2) complete with

backing pads(1)(item 18) and backing

rings(4) as follows:-

- with piston legs on

left side

of bore (when

viewed from the o-ring end of the piston),

until racks engages with pinion and then

push fully inward, the actuator is now in the

fully closed position.

Note:

If no travel stops are fitted proceed to

instruction 12.

8. Turn the pinion shaft anti-clockwise

approximately 5° until it is orientated in line

with the major axis of the actuator body. The

shaft is now in the closed position.

9. Insert CLOSE travel stop bolt (item 19/20)

together with sealing nut or lock nut (2)(3),

flat washer (2)(3) and sealing washer (2)

(3) until the bolt hits the travel stop cam.

Tighten the lock nut.

10. Turn the pinion shaft anti-clockwise through

90° to bring it back in line with the center

line of the actuator bore, the actuator is now

in the open position.

11. Insert Open travel stop bolt (item 19/20)

together with sealing nut or lock nut (2)(3),

flat washer (2)(3) and sealing washer (2)

(3) until the bolt hits the travel stop cam.

Tighten the lock nut.

ASSEMBLY - SINGLE ACTING UNITS

Note:

Please refer to the exploded views

further on.

Liberally grease actuator bore, pistons and

pinion assembly with Molyrace LT

lubricant.

Note:

The endcap spring assembly is a

complete module with the appropriate spring

preset to suit the selected duty parameters.

Spring retaining bolt threads are bonded to end

caps with threadlock sealant to ensure double

security.

Caution!

No attempt should be made to remove

or adjust spring retaining bolts.

1. Coat all ‘O’-ring seals with Molyrace LT

lubricant.

2. Output shaft assembly:-

a) Fit the top bearing assembly (item 9) into

the top bore of the actuator body (item 1)

with the outer o-ring uppermost.

b) Fit the bottom bearing assembly (item 6)

on to the bottom of the pinion shaft (item

5) with internal o-ring uppermost.

3. Insert pinion shaft assembly from underside

of the actuator as shown in the diagram

opposite.

4. Fit internal circlip (item 12) to bottom recess

of body to locate the shaft assembly.

5. Fit ‘O’-ring seals (item 13) on pistons (item 2).

6. Orientate output shaft at 45° ± 2°.

FIGURE 4

Sectioned assembly of actuator

body and output shaft

Top bearing

assembly

Gear shim as

required

See note 4

Output shaft

Bottom bearing

assembly

Internal circlip