23

en

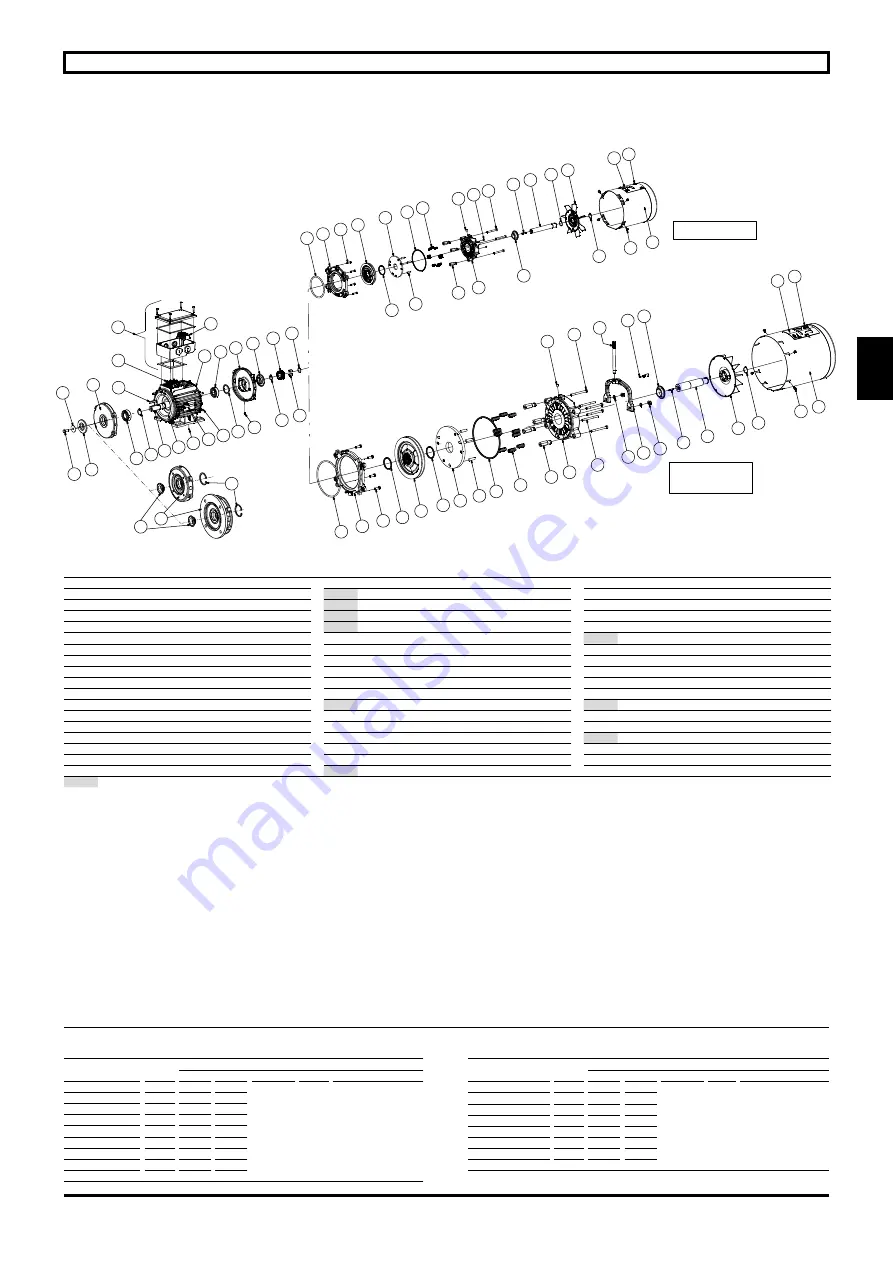

EXPLODED VIEW AND PARTS LIST OF FFB BRAKE MOTORS

FFB Brake Motors Maintenance Guide

5287 en - 2015.04 / a

1300

1303

1302

0054

0006

0050

0002

1110

0071

0084

0021

0022

0005

0023

0039

0039

0005

0030 0060

0060

0004 0001

0629 0026

0014 0059

0629

1304

1301

1300

1100

1305

1306

1101

1306

1102

1103

1107

1200

1104

1105

1500

1503 1501

1504

1400

1401

0007

0009

0027

0013

1407

1406

1402

1505

1502

1106

1108

1305

1101

1102

1107 1200

1108 1109

1106

1400

1401

0008

0007

1406 1407

0013

0027

0009

1402

1105

1104

1103

1306

1100

FFB1

FFB2 ---> FFB5

+ DLRA

IM B14

IM B3

IM B5

3 - SPARE PARTS

3.1 - Procedure

Always indicate the following when ordering spare parts:

- complete motor type, its number and the information

indicated on the information plate (refer to §1);

- serial no. of the brake information plate item 26b;

- the numbers and descriptions of the parts (record the part

marks in the exploded view §2.1 and their description in the

parts list §2.2).

For motors with a fixing flange, specify the flange and its

dimensions (IM B5 smooth holes, IM B14 tapped holes or

built-in assembly MI) and the details of the coupled reduction

gear if applicable.

To ensure proper operation and safety of our brake motors,

always use original manufacturer parts.

Maintenance kits are available. Refer to LSAS or the

following sites:

www.leroy-somer.com

or

www.emersonindustrial.com\Services-pour-systemes-d-entrainement.aspx

Otherwise, the manufacturer shall waive any liability in

case of damage.

3.2 - Spare parts

Item (item)

Type

Polarity

30

50

39

54

1101 1107 1300 1306 1402

LS 71 L, M

2; 4; 6 6202 C3 6201 C3

gasket

disc

1

gaskets

LS 80 L

2; 4; 6 6204 C3 6203 CN

(F)LS(ES) 80 LG

4

6205 C3 6204 C3

(F)LS(ES) 90 SL, L 2; 4; 6 6205 C3 6204 C3

(F)LSES 90 LU

4

6205 C3 6205 C3

(F)LS(ES) 100 L

2; 4; 6 6206 C3 6205 C3

(F)LSES 100 LG

4

6206 C3 6205 C3

(F)LSES 100 LR

4

6206 C3 6205 C3

LSES 112 M

4

6206 C3 6205 C3

Item (item)

Type

Polarity

30

50

39

54

1101 1107 1300 1306 1402

(F)LS(ES) 112 MG

2; 4; 6 6206 C3 6205 C3

gasket

disc

1

gaskets

(F)LSES 112 MU

4

6206 C3 6206 C3

LS(ES) 132 S, SU

2; 4; 6 6208 C3 6206 C3

(F)LS(ES) 132 SM, M 2; 4; 6 6308 C3 6207 C3

LSES 160 MR

4

6309 C3 6308 C3

LSES 160 MP

2 ; 4 6309 C3 6208 C3

(F)LSES 160 M

4 ; 6 6309 C3 6210 C3

(F)LSES 160 L, LR

4

6309 C3 6210 C3

1. When changing the brake disc only, the braking moment is achieved only once the friction surfaces are run in.

2 - EXPLODED VIEW AND PARTS LIST OF FFB BRAKE MOTORS

2.1 - FFB brake motor exploded view

2.2 - FFB brake motor parts list

Item

Description

Qty

Item

Description

Qty

Item

Description

Qty

1

Stator

1

30

Front bearing (DE)

1108 Wire guide (item 1105)

1

2

Housing

1

39

Front sealing gasket (DE)

1

1109 Obturating cap

2

4

Rotor

1

50

Bearing brake side (NDE)

1

1110 Brake supply unit

1

5

Front shield (DE)

1

54

Sealing gasket on brake side (NDE)

1

1200 Compression spring

3 to 10

6

Back shield (NDE)

2

59

Preload washer

1

1300 O-ring (between item 6 and item 1100)

1

7

Fan

1

60

Internal circlips (DE item 30)

1

1301 Splined ring key (item 1302)

2

8

Fan spacer (item 7)

0 or 1

71

Terminal box

1

1302 Splined ring

1

9

Locking circlips (item 7)

1 or 2

84

Terminal board

1

1303 Locking circlips (item 1302)

1

13

Fan cover

1

629

Drain hole plug

1 or 2

1304 Spacer

0 or 1

14

Assembly rods

3 or 4

1100 Friction face plate

1

1305 Fixing screw (item 1100)

3 or 4

21

Shaft end key (DE)

1

1101 Brake disc

1

1306 O-ring (item 1101)

2

22

Shaft end spacer

1

1102 Armature

1

1400 Extension/shaft link screw (item 1401/4)

1

23

Tightening screw (item 22)

1

1103 Safety pins

3 or 4

1401 Extension shaft

1

25

Lifting eye (H.A. ≥ 100)

2

1104 Adjustment spacer

3 or 4

1402 VLS gasket (item 1105)

1

26a

Motor nameplate

1

1105 Brake yoke

1

1406 Cover closing hatch

1

26b

Brake nameplate

1

1106 Fixing screw (item 1105/1100)

3 or 4

1407 Fixing screw (item 1406)

4

27

Cover fixing screw (item 13)

4

1107 O-ring

1

1500 to 1505: DLRA option (see § 6.1)

xx

Spare part

Summary of Contents for Leroy-Somer FFB Series

Page 1: ...2015 04 a en Maintenance Guide Reference 5287 en Maintenance Guide Brake motors FFB ...

Page 19: ......

Page 20: ......