UPS Specifications

38

6.0

UPS S

PECIFICATIONS

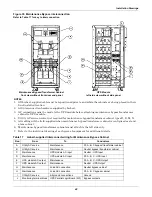

These specifications describe requirements for the Liebert NX UPS.

6.1

Conformity and Standards

The UPS has been designed to conform to the following standards:

• IEEC1000-4-5

• ASME

• CSA 22.2, No. 107.1

• FCC Part 15, Class A

• ISO 9001

• National Electrical Code (NFPA-70)

• NEMA PE-1

• OSHA

• UL Standard 1778

The UPS system has UL and c-UL approval.

6.2

UPS Environmental

The UPS is designed to operate under the following environmental conditions without damage or deg-

radation in electrical operating characteristics:

6.3

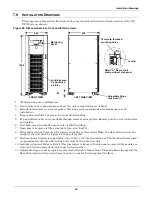

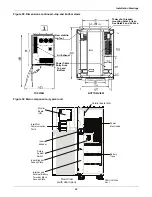

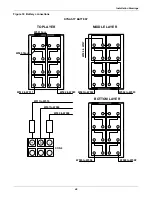

UPS Mechanical Characteristics

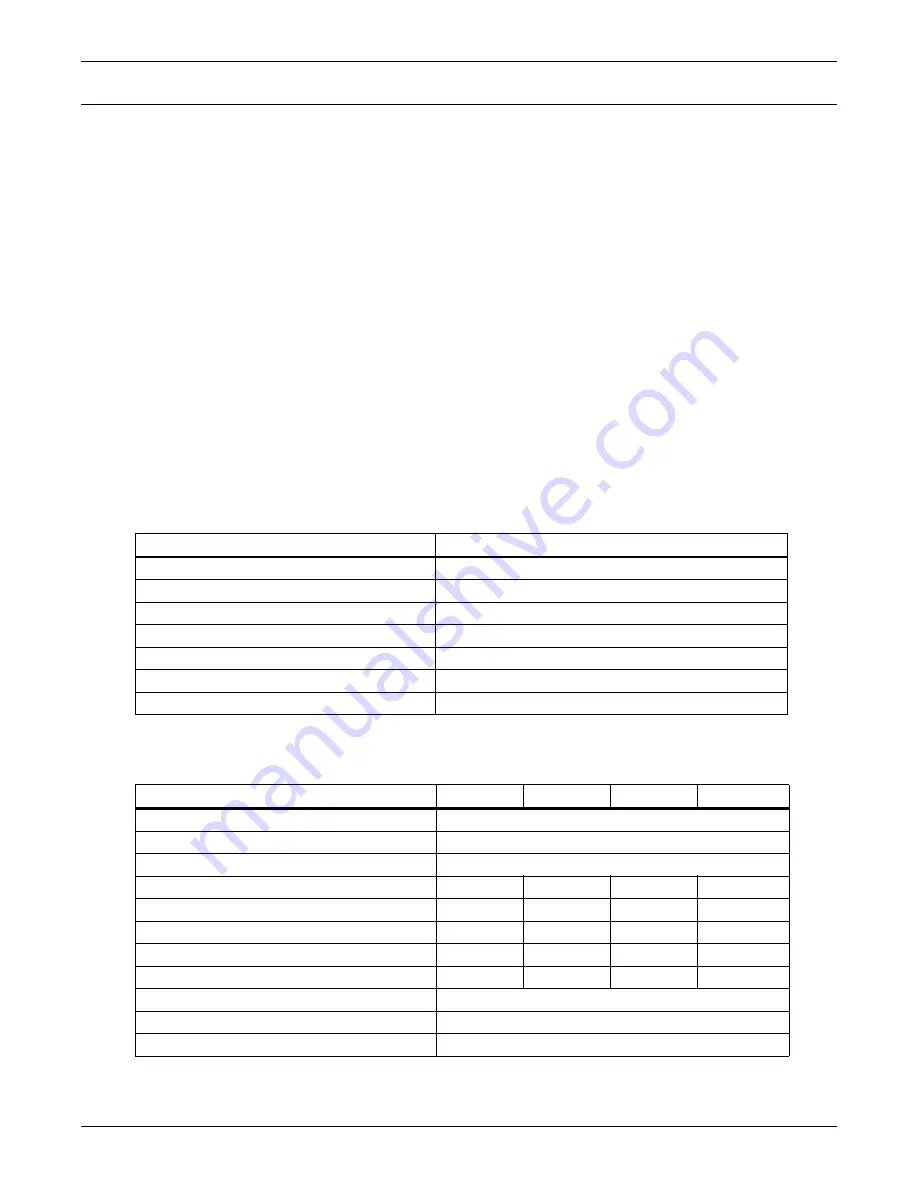

Table 8

Environmental characteristics

Rated Power

10-30kVA

Operating Temperature, UPS

32°F to 104°F (0°C to 40°C)

Optimal Operating Temperature, Battery

68°F to 86°F (20°C to 30°C)

Relative Humidity

0 to 95%, non-condensing

Acoustical Noise, dBA at 39 in. (1m)

54

Altitude of Operation

≤

1000m per IEC 62040/3

Storage-Transport Temperature, UPS

-4°F to 158°F (-20°C to 70°C)

Storage-Transport Temperature, Battery

-4°F to 86°F (-20°C to 30°C)

Table 9

Mechanical characteristics

Parameter

10kVA

15kVA

20kVA

30kVA

Width, in. (mm)

24 (600)

Depth, in. (mm)

32.5 (825)

Height, in. (mm)

63 (1600)

Weight Without Inner Batteries, lb. (kg)

450 (205)

450 (205)

550 (250)

550 (250)

UPS12-100 weight

954 (433)

954 (433)

1054 (478)

1054 (478)

UPS12-140 weight

1098 (498)

1098 (498)

1198 (543)

1198 (543)

Heat Dissipation, BTU/H (kWH)

2800 (0.82)

4200 (1.23)

5500 (1.61)

8300 (2.43)

Airflow, CFM (m

3

/h)

384 (652)

558 (948)

522 (886)

834 (1417)

Cable Entry

Bottom or top

Color

PMS 877

Protection Grade (with open/closed front doors)

IP 20