66

PACMotion VFD AC Variable Speed Drive User Guide

GFK-3111A

Group 4 Parameter Listing

WARNING

Incorrect adjustment of parameters in menu group 4 can cause unexpected behaviour of the motor and any

connected machinery. It is recommended that these parameters are only adjusted by experienced users.

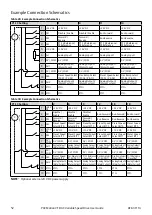

Table 38: Parameter Group 4 - Listing

Par

Parameter Name

Minimum

Maximum Default

Units

P4-01

Motor type and control mode

0

6

2

-

Setting

Motor

Type

Primary

Control

Control

Method

Additional Information

0

IM

Speed

Vector

Speed control with Torque Limit. Torque Limit Source selected

by P4-06.

1

IM

Torque

Vector

Torque Control with Speed Limit. Torque reference selected by

P4-06.

Speed Limit defined by the Speed Reference.

2

IM

Speed

V/F

V/F control for simple applications with standard IM Motors.

3

AC PM

Speed

Vector

For speed control of AC PM motors with Sinusoidal back EMF.

4

AC PM

Torque

Vector

For torque control of AC PM motors with Sinusoidal back EMF.

5

BLDC

Speed

Vector

For speed control of BLDC motors with Trapezoidal back EMF.

6

Syn RM

Speed

Vector

For speed control of Synchronous Reluctance motors.

P4-02

Motor parameter autotune

0

1

0

-

When set to 1, the drive immediately carries out a non-rotating autotune to measure the motor parameters

for optimum control and efficiency. Following completion of the autotune, the parameter automatically

returns to 0.

P4-03

Speed control P-gain

0.1

400.0

50.0

%

Sets the proportional gain value for the speed controller when operating in Vector Speed or Vector Torque

motor control modes (P4-01 = 0 or 1). Higher values provide better output frequency regulation and

response. Too high a value can cause instability or even over current trips. For applications requiring best

possible performance, the value should be adjusted to suit the connected load by gradually increasing the

value and monitoring the actual output speed of the load until the required dynamic behaviour is achieved

with little or no overshoot where the output speed exceeds the setpoint.

In general, higher friction loads can tolerate higher values of proportional gain, and high inertia, low friction

loads may require the gain to be reduced.

P4-04

Speed control I time

0.010

2.000

0.050

s

Sets the integral time for the speed controller. Smaller values provide a faster response in reaction to motor

load changes, at the risk of introducing instability. For best dynamic performance, the value should be

adjusted to suit the connected load.

P4-05

Motor power factor

0.50

0.99

-

-

When operating in Vector Speed motor control modes, this parameter must be set to the motor nameplate

power factor.

P4-06

Torque reference / limit selection

0

5

0

-

0

Maximum torque

limit P4-07

The torque controller reference / limit is set in P4-07.

1

Analog Input 1

The output torque is controlled based on the signal applied to Analog Input

1, whereby 100% input signal level will result in the drive output torque

being limited by the value set in P4-07.

2

Analog Input 2

The output torque is controlled based on the signal applied to Analog Input

2, whereby 100% input signal level will result in the drive output torque

being limited by the value set in P4-07.

3

Fieldbus

The output torque is controlled based on the signal from the

communications Fieldbus, whereby 100% input signal level will result in the

drive output torque being limited by the value set in P4-07.

4

Master / Slave

The output torque is controlled based on the signal from the Emerson

Master / Slave, whereby 100% input signal level will result in the drive

output torque being limited by the value set in P4-07.

5

PID output

The output torque is controlled based on the output of the PID controller,

whereby 100% input signal level will result in the drive output torque being

limited by the value set in P4-07.