2

PENBERTHY

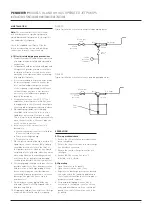

MODELS GL AND GH GAS OPERATED JET PUMPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

2 INTRODUCTION

2.1 Features and specifications

Penberthy models GL and GH gas operated jet

pumps are designed primarily for exhausting,

evacuating and priming using steam or air as

the operating medium; and for pumping water

using steam as the operating medium. They can

also be used with other gases as the operating

medium.

2.2 Design ratings at maximum and minimum

operating temperatures (see Table 1)

To determine the maximum allowable working

pressure for a specific temperature within

the design limits stated in Table 1, the user

should refer to relevant data sheets or, when

provided, the specifically stated design limits on

a product proposal.

TABLE 1 - DESIGN RATINGS AT MAXIMUM AND MINIMUM OPERATING TEMPERATURES

Material

Bodies

Nozzles

Iron

80 psig [550 kPaG] at -20°F [-29°C] to +150°F [66°C]

50 psig [340 kPaG] at + 350°F [177°C]

200 psig [1380 kPaG] at -20°F [ -29°C] to +400°F [204°C]

Bronze

200 psig [1380 kPaG] at -20°F [-29°C] to +150°F [66°C]

125 psig [860 kPaG] at + 400°F [204°C]

200 psig [1380 kPaG] at -20°F [ -29°C] to +400°F [204°C]

316 SST

200 psig [1380 kPaG] at -150°F [-101°C] to +150°F [66°C]

125 psig [860 kPaG] at + 400°F [204°C]

200 psig [1380 kPaG] at -150°F [-101°C] to +400°F [204°C]

1 ABOUT THE MANUAL

This manual has been prepared as an aid and

guide for personnel involved in installation or

maintenance. All instructions must be read and

understood thoroughly before attempting any

installation, operation or maintenance.

IMPORTANT

Emerson does not have any control over the

manner in which its jet pump is handled, installed

or used. Emerson cannot and will not guarantee

that a jet pump is suitable or compatible for the

user's specific application.

WARNING

Failure to follow any instruction could possibly

result in a malfunction of the jet pump with

resulting sudden release of pressure, severe

physical injury or property damage.

2.3 Application data

The model GL is intended to operate between

60 psig (410 kPaG) and 150 psig (1030 kPaG)

steam pressure against moderate or zero

discharge head. The model GH is intended

to operate between 20 psig (140 kPaG) and

150 psig (1030 kPaG) steam pressure against

moderate to substantial discharge head.

Note:

For specific application data within the

above ranges, the user should consult the

product proposal for the specific model and

size jet pump, or should request the supply of

the applicable technical data sheet.

WARNING

Under no circumstances should these design

ratings or application data be exceeded.

Exceeding design ratings or application data may

cause severe physical injury or property damage.

3 INSPECTION AND PERFORMANCE

CONFIRMATION

3.1 Receiving inspection

Upon receipt of the jet pump, check all

components carefully for damage incurred in

shipping. If damage is evident or suspected,

do not attempt installation. Notify the carrier

immediately and request a damage inspection.

3.2 User's rating inspection

The user should confirm that:

1. The jet pump size (cast on side of body) and

model designation (stamped on nozzle hex

flats) conforms to the description on the

user's purchase order.

2. The operating conditions described in

the purchase order agree with the actual

operating conditions at the installation site.

3. The actual operating conditions at the

installation site are within the application

data shown on the relevant technical data

sheet or product proposal referred to above.

4. The materials of construction of the

jet pump are compatible with both the

contained fluid and the surrounding

atmosphere in the specific application.

IMPORTANT

If the size, model or performance data of the jet

pump as received does not conform with any of

the criteria above, do not proceed with installation.

Contact an authorized Penberthy distributor for

assistance.