4

PENBERTHY

LED ILLUMINATOR FOR FLAT GLASS GAUGES, HAZARDOUS LOCATION

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

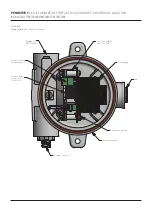

4 INSPECTION

SAFETY INSTRUCTIONS

Exercise care in handling illuminator parts to

avoid scratching, denting or otherwise damaging

the protective glass. Any marks on the protective

glass, as well as dirt, paint or tape will result

in a reduction of light output. Upon receipt of

an illuminator, check all components carefully

for damage incurred in shipping. If damage is

evident or suspected, do not attempt installation.

Notify carrier immediately and request damage

inspection. Refer to the exploded view diagram

in Sections 13-15 to inventory parts.

5 INSTALLATION

Installation should only be undertaken by

qualified personnel who are familiar with

this equipment. They should have read and

understood all of the instructions in this

manual. The user should refer to Penberthy

dimension sheets or Penberthy product

proposal to obtain dimensional information for

the specific size and model illuminator.

It is the user’s responsibility to assure that

knowledgeable installation personnel plan and

carry out the installation in a safe manner.

The following procedures are some of the

guidelines that should be employed.

5.1 Inspection and cleaning of glass

Penberthy recommends that prior to

installation of an illuminator to a gauge, that

the gauge glass be cleaned and inspected per

instructions as follows:

1. Clean glass within vision slot using a non-

abrasive household cleaner. DO NOT use

a wire brush, metal scraper or any devise

which could scratch the glass.

2. Inspect the surface of the glass for any

signs of clouding, etching, scratching or

physical damage such as bruises, chips or

erosion that penetrates the outer surface of

the glass. Shining a light at approximately

a 45º angle will aid in detecting some of

these conditions. Light will glisten more

brightly on glass imperfections than the

surrounding glass when reflecting light.

Detection of any such problem areas or

surface wear is sufficient evidence of

damage. Do not proceed with installation

with damaged glass. See appropriate

Installation, operation and maintenance

manual and replace glass.

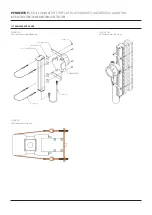

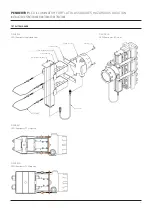

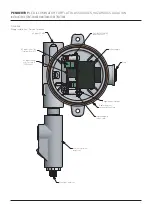

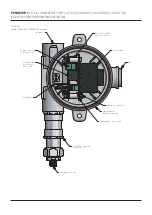

5.2 Installation of unit to gauge

Become familiar with the illuminator

components before proceeding with

installation. Refer to the exploded parts

diagram, ISO and top views in Section 13 for

transparent gauges, Section 14 for reflex

gauges, and Section 15 for TSL/TSM gauges.

As well as Figure 4A for general locations, 4B

for division locations, and 4C for ATEX/IECEx

when performing the following installation

instructions.

To assemble the illuminator to a transparent

style gauge, follow the steps below:

1. Screw the attachment plate to the slider

bracket (leave two slider brackets in the

middle-lower half of the illuminator for

the power supply).

2. Insert the eyebolt/wire assembly on one side

of the attachment plate only and fix with the

nut/wing-nut provided.

3. Position the illuminator on the gauge so that

the top end cap of the illuminator rests on

the top end of the gauge cover.

4. Position the mounting brackets with wires

where desired (3 ft. max distance between

brackets is suggested) and wrap the wire

around the gauge. Insert the other eyebolt

on the opposite side of the attachment plate

and fix with the nut/wing-nut provided.

5. Center the illuminator and firmly tighten

down the wire to hold the illuminator to the

gauge.

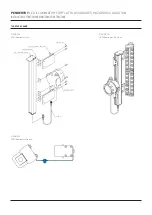

6. Open the cover of the power supply

enclosure and make sure the AC input

voltage selector switch in the power supply

matches the input voltage provided to the

unit (115 VAC or 230 VAC).

7. After voltage selector switch is selecting the

correct input voltage, connect/plug in the AC

wires to Terminal Block 1.

8. Fully close the cover of the enclosure by

hand tightening it.

9. Mount power supply to the illuminator body

using the last two slider brackets you set

aside from step 1.

10. Connect the power supply to the LED

illuminator using the cordset provided.

IMPORTANT

For Hazardous Location Only

• A flame path seal-off shall be installed within

18 in. of enclosure, see Figure 5A for Division

Locations.

• A flame path seal-off shall be installed directly

to threaded entry of enclosure, see or Figure 5B

for ATEX/IECEx.

• The LED Illuminator contains material

composition capable of igniting the explosive

atmosphere due to physical impact or friction.

Installation shall provide inherent protection

from potential impacts risks by means of

installation location, guards, and/or barriers.