NOTE

The user must provide a means to discon-

nect the main power supply in the form of

circuit breaker or switch. The circuit break-

er or the switch must be located in close

proximity to the instrument and identified

as the disconnecting device for the instru-

ment.

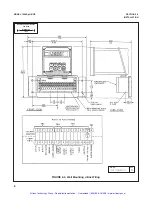

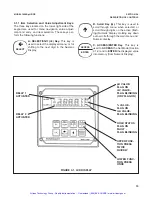

2.4.1 Power Input Wiring.

The Model 1054B can be

configured for either 115 VAC or 230 VAC power.

Connect AC power to TB1-7 and -8 (230V), or TB1-8

and -9 (115 VAC) ground to the TB3-8 (refer to

Figure 2-6).

1.

AC connections and grounding must be in com-

pliance with UL 508 and/or local electrical codes.

2.

The metal stiffener is required to provide support

and proper electrical continuity between conduit

fittings.

3.

This type 4/4X enclosure requires a conduit hub

or equivalent that provides watertight connect,

REF UL 508-26.10.

4.

Watertight fittings/hubs that comply with the

requirements of UL 514B are to be used.

5.

Conduit hubs are to be connected to the conduit

before the hub is connected to the enclosure, REF

UL 508-26.10.

6.

If the metal support plate is not used, plastic fit-

tings must be used to prevent structural damage

to the enclosure. Also, appropriate grounding lug

and awg conductor must be used with the plastic

fittings.

2.4.2 Output Wiring.

The signal output and alarm

connections are made to terminals 1 through 6 of TB1

and terminals 1 and 2 of TB3 (refer to Figure 2-6).

CAUTION

The sensitivity and stability of the analyzer

will be impaired if the input wiring is not

grounded. DO NOT apply power to the

analyzer until all electrical connections are

verified and secure. The following precau-

tions are a guide using UL 508 as a safe-

guard for personnel and property.

4

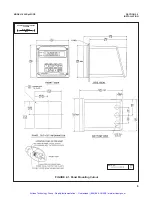

MODEL 1054B pH/ORP

SECTION 2.0

INSTALLATION

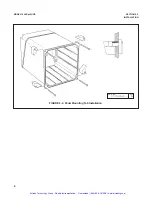

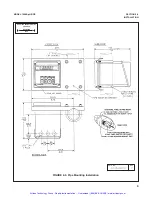

2.4 ELECTRICAL WIRING.

The Model 1054B has

three conduit openings in the bottom rear of the

analyzer housing which will accommodate

1/2

-inch

conduit fittings. From a back view, the conduit open-

ing on the left is for timer, alarm, and AC connec-

tions; the center is for signal output and the opening

on the right is for sensor wiring. AC power wiring

should be 14 gauge or greater.

The wall mount enclosure has three

3/4

-inch conduit

openings, two with

3/4

-inch fittings and one with a

NEMA 4X conduit plug. From the front view the

conduit opening on the left is for sensor wiring; the

center is for signal output, and the right is for timer,

alarm and AC power supply connections. Sensor

wiring should always be run in a separate conduit

from power wiring.

NOTE

Wall mount: use opening on the left for sensor

wiring (refer to Figure 2-4 for wiring).

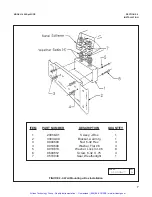

NOTE

PN 23363-00 (integral preamplifier). Refer to

Figure 2-7 for installation and wiring. PN 23508-

00 (integral preamp is for wall mount enclo-

sure). Refer to Figure 2-9.

NOTE

For maximum EMI/RFI protection the output

cable should be shielded and enclosed in an

earth grounded, rigid metal conduit. When

wiring directly to the instrument connect the

output cable‘s outer shield to the transmitter’s

earth ground via terminal 8 on TB3, Fig. 2-6.

When wiring to the wall mounting junction box

connect the output cable’s outer shield to earth

ground via terminal 6 of TB-A, Fig. 2-4.

The sensor cable should also be shielded.

When wiring directly to the instrument connect

the sensor cable’s outer shield to the transmit-

ter’s earth ground via terminal 8 of TB2, Fig. 2-

6. If the sensor cable’s outer shield is braid an

appropriate metal cable gland fitting may be

used to connect the braid to earth ground via

the instrument case. When wiring to the wall

mounting junction box connect the cable’s

outer shield to earth ground via terminal 6 of

TB-A, Fig. 2-4.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com