Quick Installation Guide

00825-0500-4809, Rev CA

September 2003

Threaded Flo-Tap 485 Annubar

S

TEP

2: W

ELD

M

OUNTING

H

ARDWARE

NOTE

Rosemount-supplied mounting includes critical alignment hardware

that assists in the correct drilling of the mounting hole. It also assists in

the alignment of the sensor to the mounting hole for insertion.

1. At the pre-determined position, place the thread-o-let on the pipe,

gap

1

/

16

in (1.5 mm), and place four

1

/

4

-in. (6-mm) tack welds at 90°

increments.

2. Check alignment of the mounting both parallel and perpendicular to

the axis of flow (see Figure 7). If alignment of the mounting is within

tolerances, finish weld per local codes. If outside of specified

tolerance, make adjustments prior to making the finish weld.

3. To avoid serious burns, allow the mounting hardware to cool

before continuing.

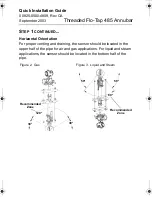

Figure 7. Alignment

(1) LMH values are as follows:

Sensor Size 1: 1.38-in. (35 mm)

Sensor Size 2: 1.56-in. (40 mm)

Sensor Size 3: 2.06-in. (52 mm)

Tack

Welds

LMH

(1)

4809-0500 Rev CA.fm Page 9 Monday, September 22, 2003 11:14 AM