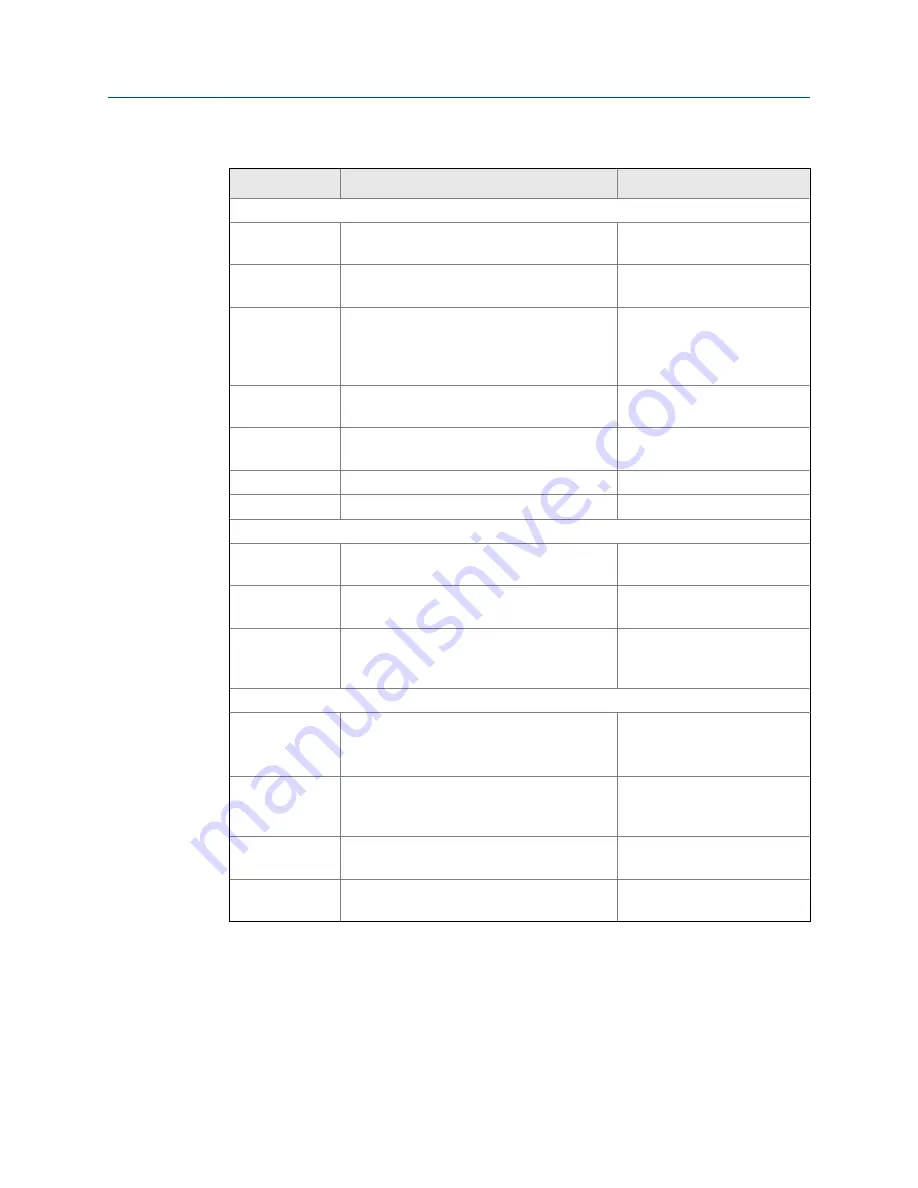

Diagnostic fault messages

Table 8-3:

Message

Description

Action

Faults

tEmP LO

Temperature is too low.

Check wiring or sensor/process

temp. Check RTD.

tEmP HI

Temperature is too high.

Check wiring or sensor/process

temp. Check RTD.

rtd FAIL

The RTD sensor line fault limits have been ex-

ceeded for the sensor.

Check wiring or Check Pro-

gram/Temp menu setting to

verify the 100-3 or 100-4 sen-

sor type connected.

CPU FAIL

The CPU has failed during RAM or EEPROM

verification.

Recycle. If persistent, contact

the factory.

FACt FAIL

The transmitter has not been accurately fac-

tory calibrated.

Contact factory.

rOm FAIL

The PROM failed the check-sum test.

Contact factory.

CyCLE PoWr

A wrong value was detected during power-up. Recycle the power.

Warnings

InPut bwArn

The compensated conductivity limit of 9999

ms/cm is exceeded.

Verify the conductivity range

setting.

OvEr rAnGE

The current range setting has been exceeded. Verify the 4 and 20 mA settings

in the Program/output menu.

AdC Error

An analog to digital conversion error has oc-

curred. (This may come up normally while

readings are changing quickly).

Recycle the power.

Errors

CAl Err or

OFFSEt Err

A calibration error has occurred between the

standard and process.

Press

RESET

and repeat.

Check calibration standards

and unit configuration.

tSLOPE Err

The limit for T-2 in a two-point calibration has

been exceeded.

Press

RESET

and repeat the cali-

brate/temp. slope menu set-

ting.

-0- Err

Sensor zero limit has been exeeded.

Press

RESET

and repeat the cali-

brate/sensor menu setting.

WritE Err

An attempt to write on the EEPROM has

failed.

The jumper JP-1 on the CPU

board has been removed.

8.2.4

Quick troubleshooting guide

Table 9-8 identifies some of the more common symptoms and suggests actions to help

resolve a problem. In general, wiring is the most common cause.

Diagnostics and troubleshooting

84

Rosemount 5081

Summary of Contents for Rosemount5081

Page 4: ......

Page 10: ...Contents vi Rosemount 5081 ...

Page 12: ...Startup procedure 2 Rosemount 5081 ...

Page 23: ...Mounting 5081 on a pipe Figure 3 2 Installation Instruction Manual 13 ...

Page 24: ...Installation 14 Rosemount 5081 ...

Page 28: ...Wiring 18 Rosemount 5081 ...

Page 50: ...Programming basics 40 Rosemount 5081 ...

Page 130: ...Diagnostics and troubleshooting 120 Rosemount 5081 ...

Page 136: ...Digital communications 126 Rosemount 5081 ...

Page 140: ...Engineering drawings 130 Rosemount 5081 ...

Page 141: ...Engineering drawings Instruction Manual 131 ...

Page 142: ...Engineering drawings 132 Rosemount 5081 ...

Page 143: ...Engineering drawings Instruction Manual 133 ...

Page 144: ...Engineering drawings 134 Rosemount 5081 ...

Page 145: ...Engineering drawings Instruction Manual 135 ...

Page 146: ...Engineering drawings 136 Rosemount 5081 ...

Page 151: ...EU Declarations of Conformity 138 Rosemount 5081 ...