© 2018 Emerson Climate Technologies, Inc.

25

AE4-1431 R1

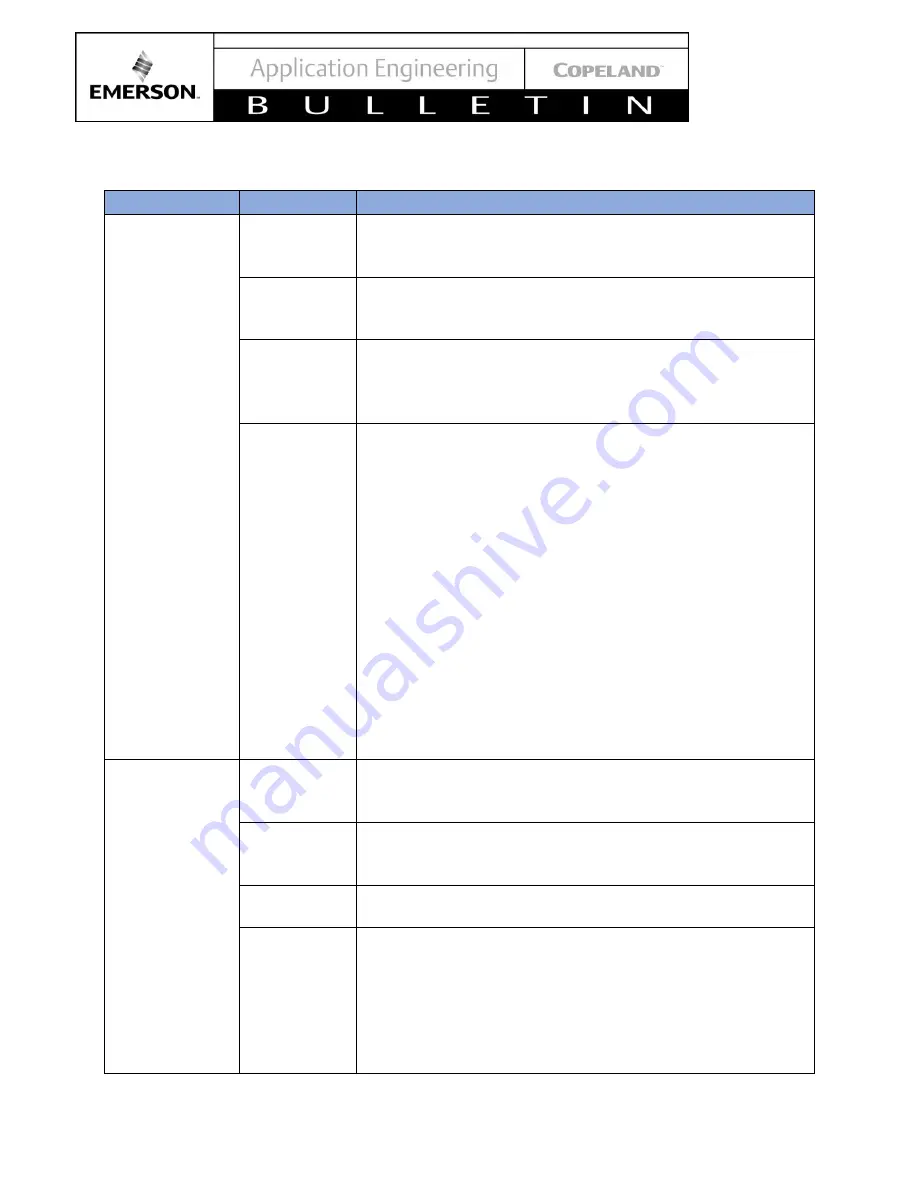

Appendix A: Common Scroll problems encountered in the field.

Condition

Cause

Corrective action

The Scroll

compressor does

not run, instead a

buzz sound can

be heard

Wired

incorrectly

Check the power supply on the compressor terminals if there is

voltage measured. Trace the wiring diagram to see where the circuit

is interrupted.

Low supply

voltage

If the voltage falls below 90% of the nameplate voltage, the motor

may develop insufficient torque. Make sure the compressor is

supplied with rated nominal voltage.

Shorted or

grounded

motor

windings

Check the motor for ground by means of a continuity check

between the terminals. If grounded replace compressor.

Internal

compressor

mechanical

damage

Refrigeration migration: When the compressor is switched off for a

long period refrigerant can condense in the crankcase. If the

compressor body is colder than the evaporator, refrigerant will

move from the evaporator to the compressor crankcase.

Refrigerant migration normally occurs when the compressor is

installed in a cold area. A pump down cycle provide good protection

against refrigerant migration.

Acid formation: Acid forms in the presence of moisture, oxygen,

metal, salts, metal oxides and/or high discharge temperatures. The

chemical reactions are accelerated at higher temperatures. Oil and

acid react with each other. Acid formation leads to damage of the

moving parts and in extreme cases to motor burnout. Several

different test methods can be used to test for acid formation. If acid

is present a complete oil change (including the oil in the oil

separator) will help. A suction filter which removes acid should also

be fitted. Check filter-drier condition.

The Scroll

compressor does

not run, no buzz

sound can be

heard

Compressor

motor

protector open

Check if there is continuity on the compressor external protector. If

the compressor is warm, it may require considerable time to cool

down.

Defective

system control

components

Check if the pressure control or thermostat works properly or if the

controls are open.

Power circuit

open

Check the fuse for a tripped circuit breaker or for an open

disconnected switch.

Burned motor

winding

If motor burned is due to undersized contactors, this is observed

when the contacts welded together. Complete motor burnout on all

three phases despite the presence of a functioning protection

system can be the result. For sizing information please consult with

Contactor manufacturer data sheet. If the application of the

compressor is changed the contactor sizing should be rechecked.

Check for unbalanced voltage.