Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation

Parameters

Technical

data

Component

sizing

Diagnostics

174

Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Subject to the limits the PID controller output is given by

output = error x [P + I/s + Ds/(0.064s + 1)]

Where:

error = reference - feedback

P = proportional gain = Pr

14.10

I = integral gain = Pr

14.11

D = differential gain = Pr

14.12

Therefore with an error of 100% and P = 1.000 the output produced by the proportional term is 100%. With an error of 100% and I = 1.000 the output

produced by the integral term will increase linearly by 100% every second. With an error that is increasing by 100% per second and D = 1.000 the

output produced by the D term will be 100%.

This parameter defines the time taken for the reference input to ramp from 0 to 100.0% following a 0 to 100% step change in input.

14.01

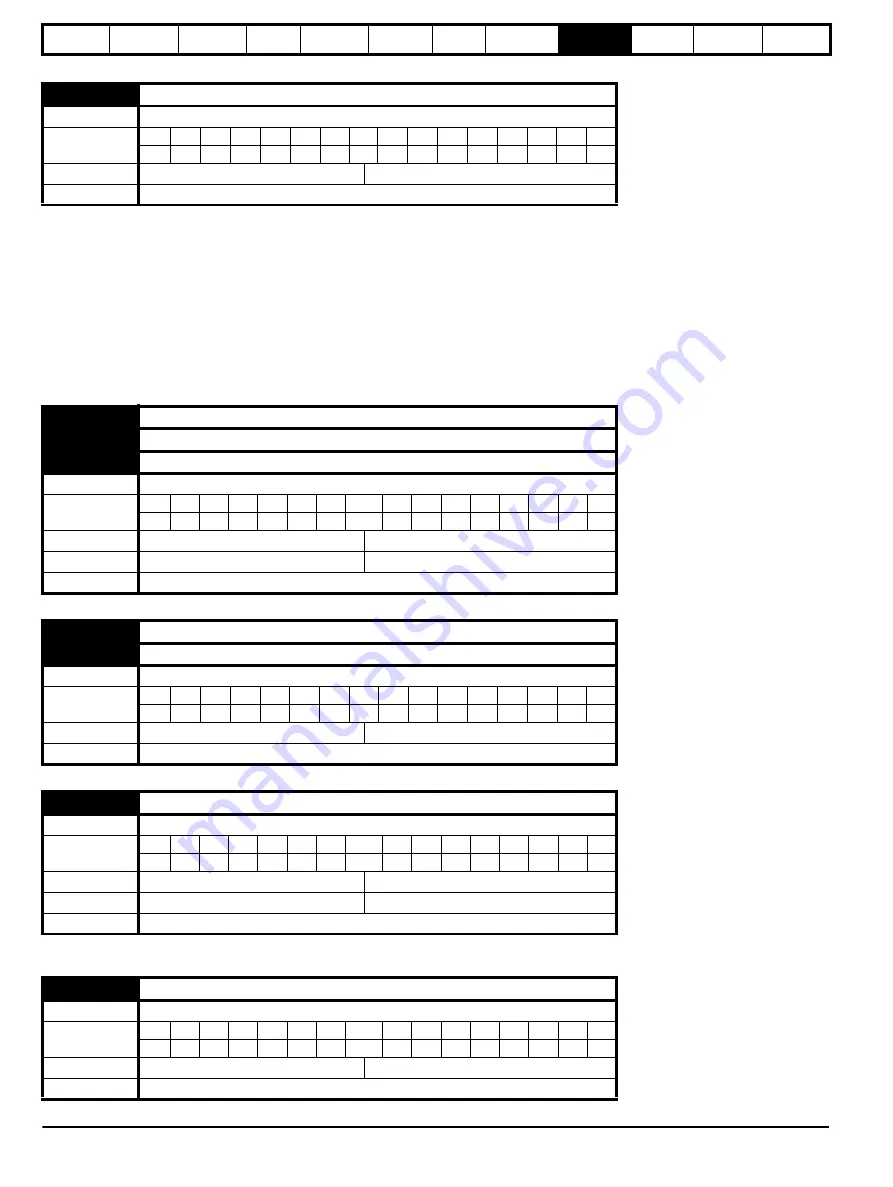

PID output

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP ND RA NC NV PT

US RW BU PS

2

1

1

1

Range

Regen

±100.00 %

Update rate

4ms

14.02

PID main reference source

14.03

PID reference source

14.04

PID feedback source

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV

PT

US RW BU PS

2

1

1

1

1

Range

Regen

Pr

0.00

to Pr

21.51

Default

Regen

Pr

0.00

Update rate

Background

14.05

PID reference source invert

14.06

PID feedback source invert

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP ND RA NC NV

PT

US RW BU

PS

1

1

1

Default

Regen

0

Update rate

4ms

14.07

PID reference slew rate limit

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV

PT

US RW BU PS

1

1

1

1

Range

Regen

0.0 to 3,200.0 s

Default

Regen

0.0

Update rate

Background

14.08

PID enable

Drive mode

Regen

Coding

Bit

SP

FI

DE Txt VM DP

ND

RA NC NV

PT

US RW BU PS

1

1

1

Default

Regen

0

Update rate

4ms

Summary of Contents for SP1201

Page 219: ......

Page 220: ...0471 0029 02 ...