15

emersonfans.com

Please contact 1-800-654-3545 for further assistance

U.L. Model No.: CF850

6. Final Assembly

(continued)

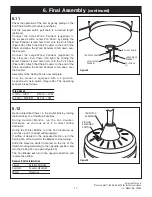

6.6

Engage the Light Kit Assembly Connector to the Motor

Connector (Figure 23) .

The Two Connectors are Keyed and Color-Coded and

must be mated correctly (color-to-color) before they can

be engaged . Make sure the Connector Latch closes

properly .

NOTE: Make sure all wires and connector are

tucked under the light kit assembly and not

pinched between light kit assembly and lower

housing.

LIGHT KIT ASSEMBLY

LIGHT KIT ASSEMBLY WIRE

CONNECTOR

MOTOR HOUSING WIRE

CONNECTOR

Figure 23

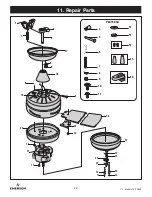

6.7

Remove One #8 - 32 x 10mm Pan Head Screw from

the Lower Housing (retain for later use) .

Loosen the other Two Screws to assemble the Light Kit

Assembly to the Lower Housing (Figure 24) .

REMOVE ONE

#8 - 32 x 10mm

PAN HEAD SCREW

LOWER

HOUSING

LOOSEN TWO #8 - 32 x 10mm

PAN HEAD SCREWS

Figure 24

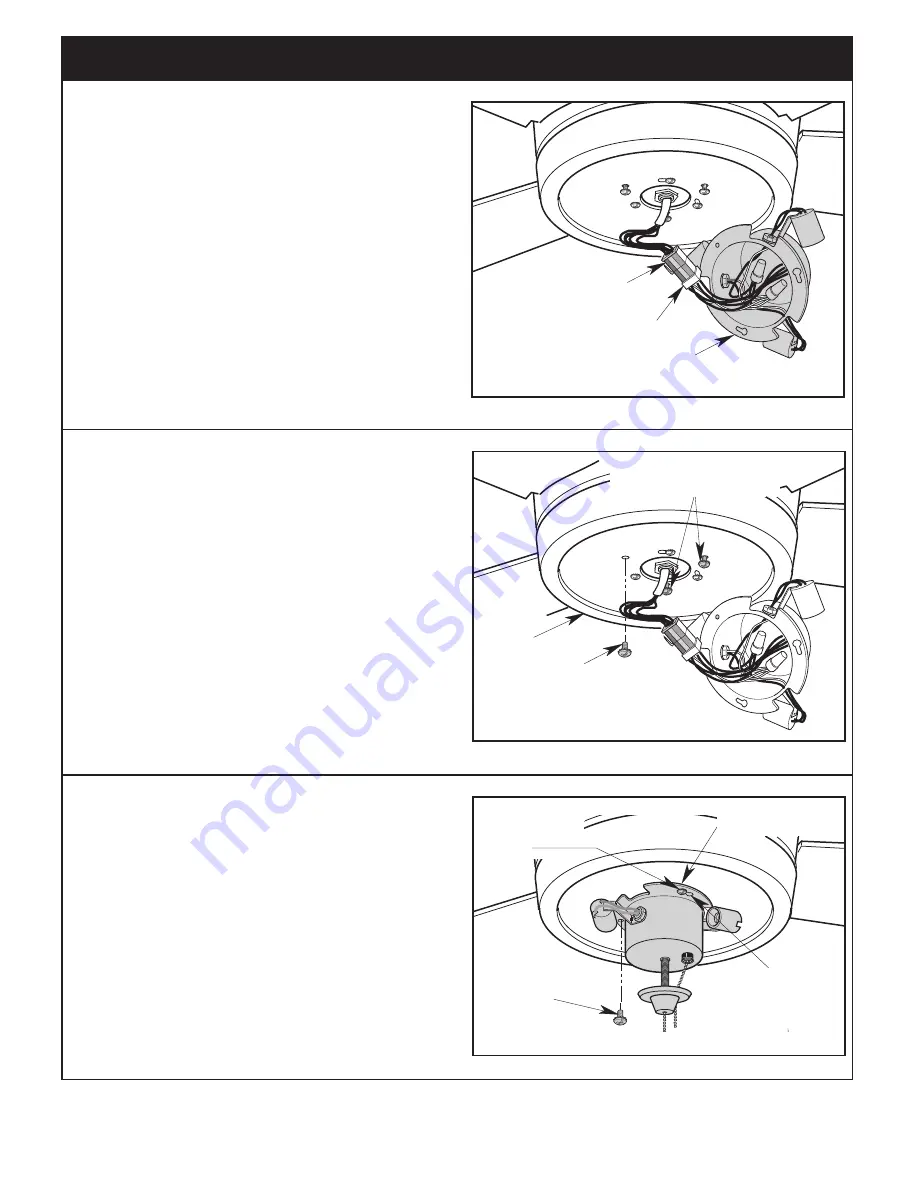

6.8

Position the Light Kit Assembly onto the Lower

Housing, aligning each of the the Three Holes .

Rotate the Light Kit Assembly to engage the Two

Loosened Screws in the Two Key Hole Slots .

Replace the previously removed #8 - 32 x 10mm Pan

Head Screw and tighten all Three Screws to secure the

Light Kit Assembly to the Lower Housing (Figure 25) .

REINSTALL AND

TIGHTEN ONE

#8 - 32 x 10mm PAN

HEAD SCREW

KEY HOLE

SLOT (2)

RETIGHTEN TWO

#8 - 32 x 10mm PAN HEAD

SCREWS

LIGHT KIT ASSEMBLY

Figure 25

Summary of Contents for SUMMERHAVEN LED CF850GES01

Page 22: ...22 U L Model No CF850 Notes ...