In salt spray environments, it is

especially important to ensure that the

enclosure is sealed properly, including

all entry and exit points.

• Always install the ROC809 in a user-

supplied enclosure.

• If the ROC809 is installed outside

a building, it must be placed in a

National Electrical Manufacturer’s

Association (NEMA) 3 or higher rated

enclosure to ensure the necessary

level of protection.

• The ROC809 operates over a

wide range of temperatures.

In extreme climates it may be

necessary to provide temperature-

controlling devices to maintain

stableoperating conditions.

• In extremely hot climates, a filtered

ventilation system or air conditioning

may be required.

• In extremely cold climates, it may be

necessary to provide a thermostatically

controlled heater in the sameenclosure

as the ROC809.

• To maintain a non-condensing

atmosphere inside the ROC809

enclosure in areas of high humidity,

it may be necessary to add heat

or dehumidification.

I/O Configuration

Several options are available on the Type ROC809

controller. Outputs may be added to interface

with external devices such as systems for remote

data transmission, remote monitoring and remote

surveillance. Table 2 lists the minimal requirements.

NOTICE

Each module must be inserted in the

assigned slot as shown in Table 2.

Further configuration information is provided in the

Type Dosaodor-D Software for Configuration

of Type Dosaodor-D Odorant Injection System

Manual (D103117X012).

Refer to the ROC809 Remote Operations Controller

Instruction Manual (Form A6116).

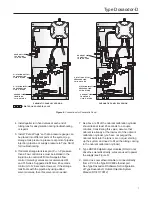

Electrical Connections Schematics

The electrical connections between the enclosure and

pneumatic panel should be completed according to

Figures 7 and 8.

Preliminary Checks

Before turning on the electronic control unit:

1. Gas Volume/Gas Delivery signal type must be set

to one of the following input signals:

• Pulse input

• Analog input

• Internal Orifice

• Internal Turbine

2. Check all of the electrical and pneumatic

connections for proper conformity throughout the

entire system, using the diagrams and drawings

supplied by the system integrator.

3. Make sure that all of the valves for connection

between the pneumatic panel and remaining part

of the station are leak free. Turn on the electronic

control unit.

Control Unit Power-On and

Parameters Set-Up

After all of the checks in the preceding section and

suggested by the system integrator have been carried

out, turn on the system, set it in Disable mode and

configure parameters as described in:

“

Procedure and Compilation of Work Parameters

”

chapter of

Type Dosaodor-D Software for

Configuration of Type Dosaodor-D Odorant

Injection System Manual (D103117X012)

.

Programmed and Displayed Data

Please refer to Type Dosaodor-D Software for

Configuration of Type Dosaodor-D Odorant Injection

System Manual (D103117X012).

11

Type Dosaodor-D