Electrical Connections

28

Installation, Operation, and Maintenance Manual

ES-09373-1

Electrical Connections

August 17, 2022

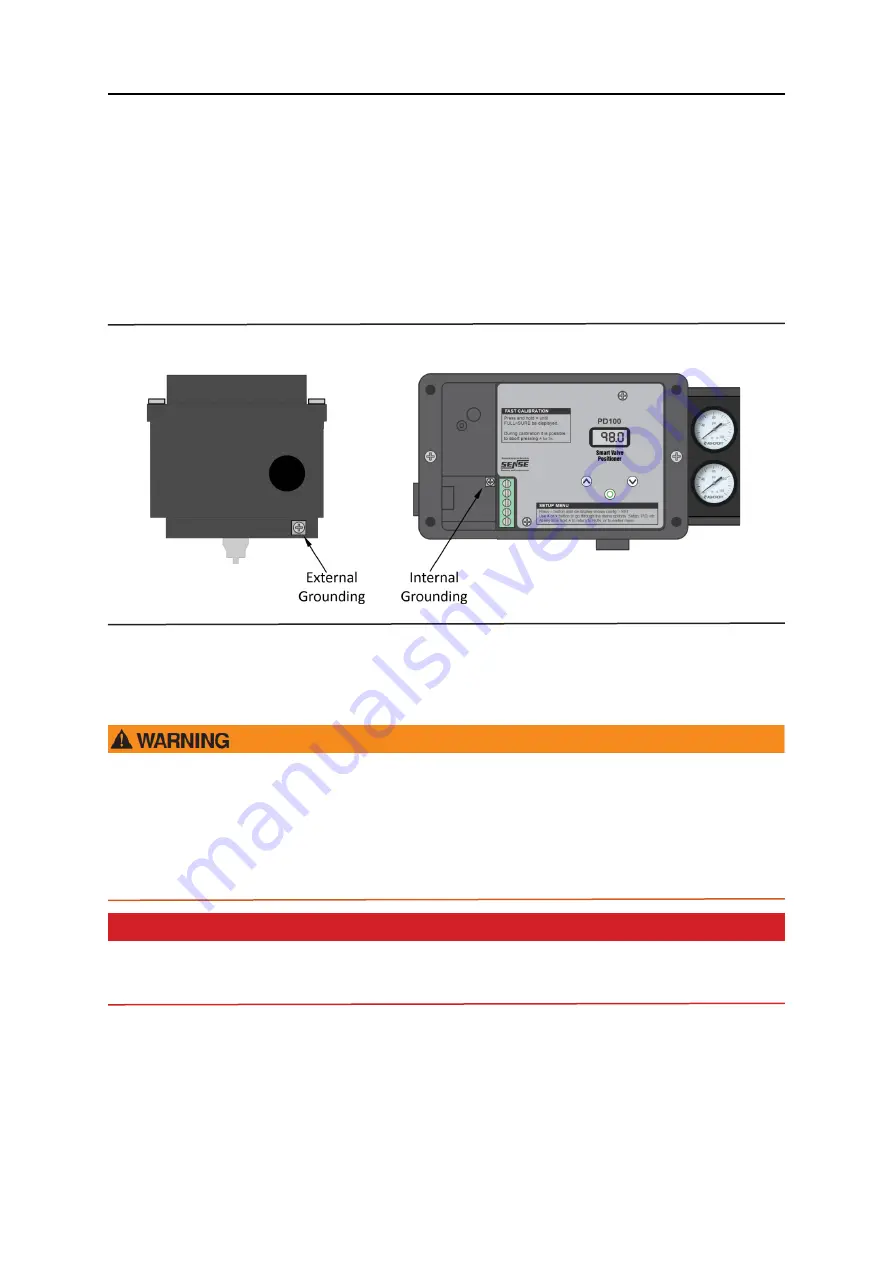

7.2 Grounding

Grounding the positioner is extremely important and highly recommended. Two

grounding points are provided, one internal and one external. If the cable used

is shielded, it is recommended that the shield be grounded at one end only. The

ungrounded end should be carefully isolated.

Figure 7-2 Grounding Screws

7.3

Electrical Connection

The PD100 is equipped with screw terminals intended for connection of the control

signal and feedback signal.

Be sure to supply the rated voltage and current indicated in this manual (see

Section 2 - Technical Specifications. Failure to do so may cause serious damage or

malfunctioning of the positioner. Despite the polarity indications, reversing them

does not alter the positioner’s operation.

When it is necessary to open the positioner’s cover in a damp place, great care must

be taken. This may cause serious damage or malfunction of the electronic circuitry.

Before installing the positioner, check the area classification. Never use a General

Purpose positioner in an area classified as an explosive atmosphere.

DANGER